When it comes to managing inventory and tracking products, two critical terms often come into play: SKU and barcode. While often used interchangeably, these two identifiers serve unique purposes in the retail and warehousing sectors.

This article aims to clarify the differences between SKU and GTIN, comparing their roles in business operations. We’ll define each term, explore their use in practice, and highlight their impact on product management efficiency and overall organisational effectiveness.

So, without further ado, let’s get started.

SKUs, or Stock Keeping Units, are alphanumeric codes that businesses create to internally track their inventory and understand product performance. Think of them as unique identifiers for every identical product in a store or warehouse.

For example, an SKU might commence with alphabetic characters denoting the product category, like ‘TS’ for t-shirts. Then, additional specifics such as colour and size are included, resulting in a code like ‘TS-RD-M,’ signifying a medium-sized red t-shirt.

For a deeper dive into SKUs and to fully grasp their significance, refer to our dedicated article, What is a SKU?

Barcodes are a universal, scannable symbol that uses lines and spaces of varying widths to encode product information in a machine-readable format. Each barcode contains a specific pattern that corresponds to a set of numbers or characters.

When scanned by a barcode reader, this pattern is translated into digital data that a computer system can process. There are several types of barcodes, such as UPC, EAN, GTIN, QR codes and Data Matrix codes. These standardised formats ensure consistency and ease of use across global retail and supply chains.

To deepen your understanding of barcodes and their diverse types, we’ve curated a selection of articles that cover everything from the basics to more complex distinctions.

Here’s where you can start:

Our Barcode Learning Centre is your go-to resource for a more in-depth exploration, offering a wealth of information to satisfy your curiosity and enhance your knowledge.

The relationship between SKUs and barcodes is often misunderstood. While they intersect in inventory management, their roles and applications are fundamentally different.

SKUs act as an internal language for businesses, allowing them to categorise and manage products according to their unique systems and strategies. They are akin to a personalised filing system, adaptable to the specific nuances of each business’s inventory.

Barcodes, in contrast, serve as the universal identifiers in the retail world. They are the bridge between a product and the vast network of global retail and supply chains. They ensure that a product can be recognised and tracked worldwide.

Let us first take a quick look at the points of difference between the two:

Aspect | SKUs | Barcodes |

|---|---|---|

Origin | Created internally by individual businesses.

| Standardised formats; Are developed globally.

|

Purpose | Used for internal inventory management. | Used for universal product identification and tracking.

|

Format | Alphanumeric, often customised.

| Scannable, consisting of lines and spaces.

|

Scope | Specific to a single business or its network.

| Universally recognised and used.

|

Integration | Integrated into internal management systems.

| Integrated into POS systems and used in global logistics.

|

Flexibility | Highly flexible; Can be tailored to business needs.

| Standardised; No flexibility.

|

Data Encoding

| Can encode a wide range of information about the product.

| Typically encodes basic product information like manufacturer and product ID, to more complex data like serialisation and URLs.

|

Impact on Operations

| Facilitates detailed internal analysis and decision-making.

| Streamlines external processing like sales and inventory tracking.

|

Now that we have discussed the differences briefly, let us take a closer look at each of them to understand them in greater detail.

SKUs originate within a business and are crafted to align with its inventory management and organisational strategies. They are unique to each company, allowing for a tailored approach to categorising products based on internal criteria.

Barcodes have a standardised origin, developed for universal application across industries. This global standardisation ensures that a product’s barcode is the same everywhere, facilitating widespread recognition and compatibility in retail and supply chains.

SKUs are internal identifiers that enhance inventory control and data analysis for businesses, enabling precise stock and sales management. They allow for detailed differentiation within a company’s product range, aiding in targeted strategies and efficient replenishment.

Barcodes, in contrast, provide a standardised method for product identification across the global retail and logistics sectors. They facilitate quick transactions, streamline supply chain operations, and ensure universal trackability of goods from production to point of sale.

Employing SKUs and barcodes allows businesses to optimise internal operations while ensuring compatibility with external systems, marrying detailed internal management with broad market engagement.

SKUs and barcodes utilise distinct formats that cater to their specific roles in inventory management and product identification.

SKUs are alphanumeric, blending letters and numbers to encapsulate detailed product information such as type, size, and colour. This format’s flexibility allows businesses to tailor the structure to their internal needs, organising and encoding data in a way that best supports their inventory management processes.

Conversely, barcodes are visual symbols consisting of lines and spaces of varying widths representing data in a machine-readable form. This standardised format is designed to be scanned by optical devices, translating the encoded information into digital data that a computer system can process.

SKUs integrate into internal inventory systems, customised for specific business needs. They stay within the company’s network.

Barcodes integrate externally in sales and supply chains, following global standards for universal recognition and tracking from manufacturer to consumer.

SKUs are highly flexible as they offer a high degree of customisation. This enables businesses to incorporate detailed information about product attributes, such as type, size, colour, and more, into their inventory codes. This flexibility allows for precise internal management and categorisation tailored to the company’s needs.

In contrast, barcodes follow a universal format with limited customisation. They are designed to encode a product’s essential information, such as manufacturer and item number, in a way that is recognised globally. This ensures consistency in product identification across different retail environments.

For example, a barcode on a shampoo bottle remains the same whether it’s sold in New York or Paris, simplifying inventory tracking and management for retailers worldwide.

SKUs are alphanumeric codes, providing a rich, flexible canvas for encoding a wide array of product-specific details internally within a business.

Barcodes encompass a variety of formats, such as UPCs, EANs, QR codes, Code 39, Code 128, and ITF-14, among others. Each format offers unique capabilities for data encoding, from simple numeric information to extensive alphanumeric data. This diversity enables applications ranging from basic product identification and tracking to complex information sharing.

SKUs streamline internal inventory management, enabling precise tracking, efficient order fulfilment, and targeted marketing, directly enhancing customer satisfaction and operational efficiency.

Barcodes facilitate quick, accurate scanning for sales and logistics, improving checkout speed, supply chain transparency, and interoperability across stakeholders, reducing costs and enhancing service.

The decision between SKUs and barcodes—or the integration of both—depends on your business’s specific needs and objectives.

If your business prioritises detailed internal inventory management, desires precise tracking of product variations, and aims for in-depth data analysis to inform restocking and marketing strategies, then adopting SKUs is the way forward.

SKUs offer unparalleled customisation and detail, allowing you to categorise products based on various attributes such as type, size, colour, and more. This level of granularity is essential for businesses looking to optimise their internal operations, from warehouse management to sales forecasting.

On the other hand, if your focus is on universal product identification, facilitating quick and accurate transactions, and ensuring efficient logistics and supply chain management, barcodes should be your choice.

Barcodes provide a standardised method for product identification across different markets and supply chains, making them indispensable for businesses that operate on a global scale or rely heavily on external distribution and retail networks.

They streamline checkout, shipping, and receiving processes, enhancing operational efficiency and customer satisfaction.

Assessing the complexity of your inventory, the scope of your market engagement, and your operational priorities will guide you in choosing the right system to support your business’s success.

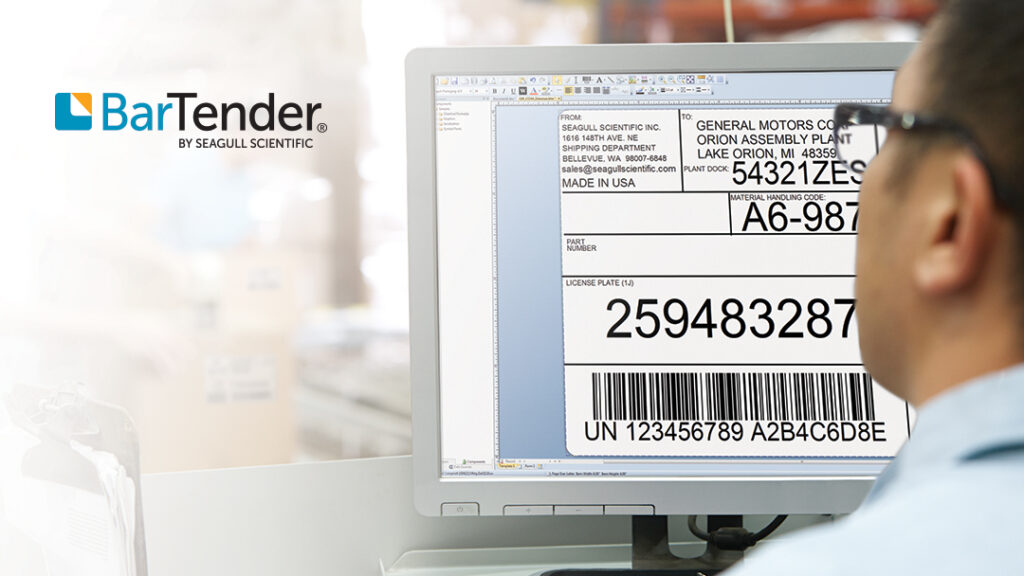

Efficient inventory management and product tracking are pivotal for any business, and creating barcodes and SKUs is at the heart of this process. A leading solution in this area is Seagull Scientific’s BarTender Software, renowned for its ability to simplify and enhance the design of both SKU and barcode labels.

BarTender Software stands out as a comprehensive tool for designing and printing labels, barcodes, RFID tags, and more. It features a specialised SKU template that easily links to databases, significantly easing the SKU label creation process.

Boasting over 400 pre-formatted barcode components and supporting 105 symbologies, BarTender meets a broad spectrum of industry standards. Its adaptability is further underscored by its capacity to integrate with various data sources, including databases and CSV files, alongside its date/time serialisation functionality.

For those interested in exploring all that BarTender has to offer, our What is BarTender? Guide is a great starting point.

At Triton Store, we offer all four editions of BarTender software: Starter Edition, Professional Edition, Automation Edition and Enterprise Edition. We also provide the latest BarTender Cloud, a cloud-based solution for remote label printing and management, accessible from anywhere.

To discern the differences between BarTender Cloud and its on-premise alternatives, our BarTender Cloud vs BarTender Software guide provides detailed comparisons.

If you’re considering upgrading your labelling system or have specific queries, we’re here to assist. Reach out to us through our live chat widget or by completing a form on our website. Allow Triton Store to guide you to the ideal BarTender labelling solution tailored to your business’s unique needs.

In wrapping up, the strategic deployment of SKUs and barcodes is pivotal for streamlining inventory management and operational workflows. The insights provided aim to empower businesses with the knowledge to make informed decisions tailored to their unique operational landscape.

Embracing the right mix of these tools can unlock efficiencies, improve accuracy, and foster growth, ensuring businesses meet and exceed their operational and customer satisfaction goals in a competitive marketplace.

Yes, SKUs and barcodes can be integrated within a single inventory management system to leverage both strengths.

SKUs provide detailed internal tracking and management capabilities, while barcodes offer standardised external identification for products. Together, they enable businesses to maintain precise control over inventory while ensuring products are easily identifiable and trackable across global supply chains.

Inventory changes, such as introducing new products or discontinuing old ones, require SKU and barcode system updates.

For SKUs, businesses must generate new codes aligning with their internal categorisation and tracking systems. New products must be registered for barcodes to receive a unique barcode that conforms to global standards.

Small businesses may face challenges such as the initial setup cost, employee learning curve, and integrating these systems with existing software.

Implementing SKUs requires developing a customised coding system that can scale with the business, while adopting barcodes involves choosing the right type of barcode and ensuring compatibility with suppliers and retailers. However, the long-term benefits of improved inventory management and operational efficiency can outweigh these initial challenges.

Yes, SKUs and barcodes can be customised to meet the specific needs of different industries. SKUs can be designed to include information relevant to the industry, such as batch numbers for pharmaceuticals or style codes for fashion.

Barcodes, while standardised, can be selected based on the type of data encoding needed, such as QR codes for additional product information or Code 128 for logistics.

SKUs and barcodes are crucial in managing inventory and sales on online platforms.

SKUs help online retailers organise product listings, track inventory levels, and analyse sales data. Barcodes are used to process orders efficiently, especially when fulfilling online orders from physical stock.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below