Barcodes are key to tracking products, information, and services swiftly and accurately. Security labels are vital within this ecosystem, ensuring data remains intact and authentic.

The integrity of barcodes is upheld by standards from the International Organisation for Standardisation (ISO). ISO standards are crucial for global uniformity. They help maintain consistent quality and reliability across borders, industries, and technologies.

This article will delve into the importance of ISO standards in barcode verification. We aim to enlighten our readers on the various ISO standards and their significance in enhancing the security and efficiency of barcode systems.

For an essential overview of barcodes and their various types, consult our comprehensive guide, What is a Barcode? and Barcode Types.

The International Organisation for Standardisation (ISO) is integral to establishing global benchmarks that promote quality, safety, efficiency, and interoperability across various sectors, including the standardisation of barcodes.

By setting comprehensive guidelines for barcode design, printing quality, and data encoding, ISO ensures that barcodes are universally readable and scannable. This helps support seamless international trade and the efficient management of global supply chains.

ISO’s barcode standards ensure that barcodes, whether traditional linear (1D) or complex two-dimensional (2D) symbols, adhere to a uniform format. This uniformity is crucial for the reliable exchange of information, facilitating the tracking of products and inventory management across industries worldwide.

To learn about 1D barcodes and 2D barcodes, refer to our comparative guide, 1D vs 2D Barcodes.

The standards cover the essentials of barcode creation, from information arrangement to verification methods. This ensures their readability and interoperability across different systems and devices.

The ISO categorises barcode standards to streamline global practices. Key standards include.

Each standard targets specific aspects of barcode creation and usage, ensuring compatibility, efficiency, and security across international supply chains. This section will explore these standards, focusing on their applications and contributions to the integrity of barcode systems.

ISO/IEC 15415 establishes essential quality benchmarks for two-dimensional (2D) barcodes, such as QR codes and Data Matrix codes. It emphasises parameters such as symbol contrast, modulation, reflectance, and print growth, aiming to optimise readability and scanning efficiency.

The ISO/IEC 15415 standard ensures that 2D barcodes are designed and printed to facilitate accurate decoding by scanners in diverse environments. This enhances data exchange and inventory management.

The standard includes a detailed grading system that ranges from A (highest readability) to F (insufficient quality). It focuses on aspects like error correction levels and the physical integrity of the barcode. This grading system helps businesses assess the reliability of their barcodes, ensuring seamless operations and compliance with international trade regulations.

Applying ISO/IEC 15415 in real-world scenarios, such as supply chain management, highlights its significant impact on operational efficiency. Industries adopting this standard have seen minimised errors in logistics and retail, underscoring its role in supporting the global movement of goods. It ensures that barcodes created in one country can be accurately scanned in another, facilitating international commerce.

ISO/IEC 15416 sets quality criteria for one-dimensional (1D) barcodes, like UPC, EAN, and Code 128. It zeroes in on attributes crucial for scanning accuracy: edge contrast, minimum reflectance, symbol contrast, and modulation.

ISO/IEC 15416 standard is key in various sectors, ensuring 1D barcodes meet quality levels for reliable scanning in logistics and retail settings. This boosts data capture and asset tracking efficiency.

It introduces a grading system from A to F, with A being the best and F indicating poor quality. This grading helps organisations assess their barcodes’ performance, which is crucial for smooth operations and global commerce compliance.

In practice, ISO/IEC 15416 enhances inventory and supply chain management. It helps businesses reduce tracking errors and improves goods distribution reliability. This standard is vital for international trade, ensuring barcodes meet a globally recognised quality benchmark.

ISO/IEC 15459 establishes a system for the unique identification of items. It provides standards for assigning clear identifiers to objects for tracking and identification. This series addresses various identification aspects, including identifier structure and issuing agency registration.

The series includes multiple parts, each targeting different identification facets, like logistic units, products, and entities. ISO/IEC 15459’s consistent identification method ensures smooth system and organisation integration, vital for efficient goods and information exchange.

ISO/IEC 15459 is crucial in logistics, manufacturing, and retail for distinct item recognition and traceability across the global supply chain. This enhances inventory accuracy and operational efficiency.

In practice, ISO/IEC 15459 reduces supply chain errors, enhances goods tracking from production to consumer, and aids in meeting international regulations. It guarantees that products from one region are easily managed upon arrival elsewhere, supporting global trade and secure goods distribution.

ISO/IEC 15459, unlike ISO/IEC 15415 and ISO/IEC 15416, focuses on identification over print quality. While the latter ensures barcode readability, ISO/IEC 15459 ensures that each barcode is a unique identifier. This highlights how these standards work together within the barcode technology ecosystem.

ISO/IEC 15418 sets guidelines for encoding information in barcodes and electronic product codes (EPC), focusing on data structure and semantics. This standard ensures that product and logistical information is consistent and understandable across industries like retail and transportation, regardless of technology or location.

ISO/IEC 15418 outlines the systematic organisation of information in barcodes using data identifiers and application identifiers. This organisation allows for the uniform interpretation of data, boosting supply chain efficiency by ensuring accurate worldwide product tracking and management.

ISO/IEC 15418 also adapts to include technologies like RFID with traditional barcode systems. This adaptability meets the changing needs of digital commerce and inventory management, promoting smooth data exchange.

ISO/IEC 24731 focuses on applying RFID (Radio Frequency Identification) technology to boost the security and efficiency of tracking systems. It offers guidelines for RFID use in various settings, such as inventory management and asset tracking, to enhance operational security and data integrity.

For a deeper understanding of how RFID technology can be utilised for asset tracking and inventory management, explore our detailed how-to guides: RFID Asset Tracking and RFID Tags for Inventory Management.

By detailing the technical characteristics and data protocols for RFID systems, ISO/IEC 24731 ensures their smooth operation across different environments and industries. It covers important areas like data storage, transmission security, and how RFID can work with existing barcode systems. This helps integrate RFID into current supply chains and logistics operations smoothly.

A key aspect of ISO/IEC 24731 is its emphasis on RFID technology’s security features. It standardises data encryption and communication between tags and readers, reducing the risk of unauthorised access and data breaches. This is vital for sectors dealing with sensitive information or valuable assets.

Unlike barcode standards, ISO/IEC 24731 delves into wireless communication, offering a technology that complements traditional barcode systems. While barcode standards focus on barcodes’ physical and data quality, ISO/IEC 24731 brings these principles into the digital realm. It provides a robust framework for secure, wireless data exchange.

ISO standards for barcode technology are critical for several key reasons, each contributing to the overall effectiveness and reliability of barcode systems worldwide. Here are the main points, organised as separate sections for clarity:

ISO standards facilitate a universal language for barcodes, allowing them to be scanned and interpreted anywhere in the world. This is essential for international trade, where products frequently cross borders and must be tracked and managed by various systems.

ISO standards specify secure encoding and printing methods, significantly reducing the risk of counterfeit or tampered products. Industries like pharmaceuticals and food rely on this for consumer safety and regulatory compliance

ISO standards streamline supply chain processes by providing barcode quality and readability guidelines. This results in accurate tracking, inventory management, and data collection, leading to cost savings and improved customer service.

ISO standards are regularly updated to reflect advancements in barcode and scanning technology. This ensures that businesses using these standards are well-positioned to adopt new technologies and remain competitive.

These aspects underline ISO standards’ comprehensive role in optimising barcode systems for security, efficiency, and global interoperability.

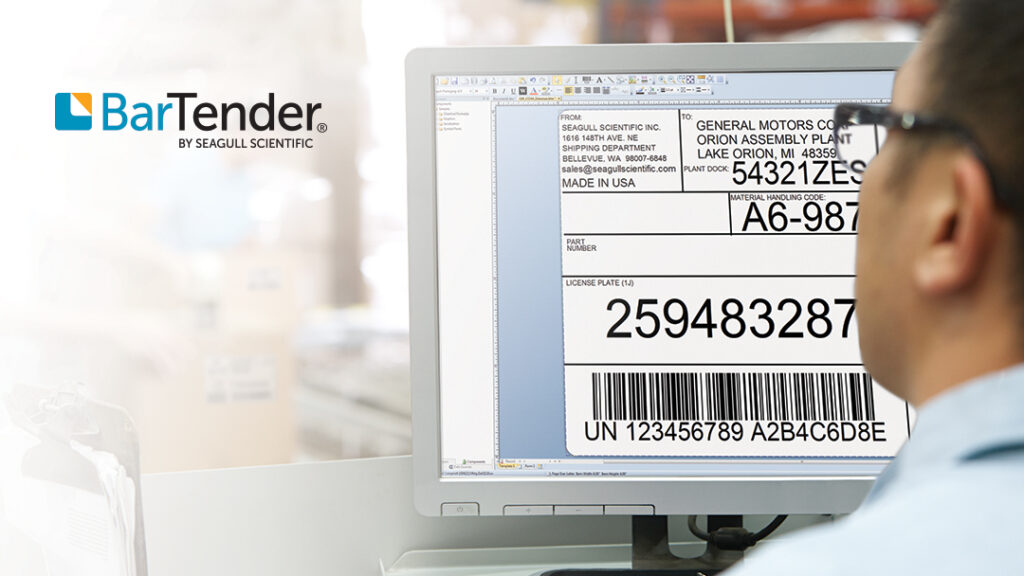

Mastering the intricacies of ISO compliance in labelling and barcode generation presents a formidable challenge for businesses committed to adhering to international standards. Seagull Scientific’s BarTender Software offers a pivotal solution, streamlining the adherence to diverse ISO mandates with remarkable ease.

As the global leader in label design and printing software, BarTender by Seagull Scientific facilitates the creation of comprehensive labels incorporating images, text, barcodes, or RFID tags. It significantly automates and refines the labelling and printing workflows, enhancing operational efficiency.

BarTender distinguishes itself in barcode generation with its expansive library, which encompasses over 400 preformatted, ready-to-use components and supports more than 105 symbologies along with a wide spectrum of barcode standards. BarTender’s user-friendly interface empowers users to craft labels that are compliant with ISO standards and perfectly aligned with the company’s branding and operational requisites.

Furthermore, BarTender’s seamless software integration capabilities indicate that achieving compliance does not necessitate overhauling existing workflows. Its compatibility with ERP, WMS, and various management systems allows for the automated generation of labels and barcodes, fostering consistent adherence to compliance standards without compromising productivity.

To accommodate diverse business needs, BarTender offers several editions, each tailored to different organisational requirements.

In addition to the four on-premise solutions, Seagull Scientific also offers a cloud-based solution named BarTender Cloud. This next-generation SaaS platform allows users to create, manage, and print labels from any location at any time, eliminating the need for additional IT infrastructure or resources.

To compare this cloud-based solution with traditional BarTender software, refer to our BarTender Cloud vs BarTender Software article.

To summarise, ISO standards are the backbone of effective barcode use, ensuring global compatibility, enhanced security, operational efficiency, and encouraging innovation. These standards are crucial for businesses aiming for quality and reliability in their operations.

Following ISO standards isn’t just about meeting requirements; it’s about making a solid commitment to operational excellence. It streamlines operations, enhances supply chain transparency, and elevates customer trust.

As we look forward, ISO standards will continue to guide the advancement of barcode technologies, securing their place as essential tools in global trade and information exchange. Embracing these standards is key for any organisation striving for success and efficiency in the international marketplace.

We hope this article was useful.

Thanks for reading!

AIM DPM (Direct Part Marking) refers to guidelines set by the Association for Automatic Identification and Mobility (AIM) for marking parts directly with a barcode. DPM is used for durability in various environments. ISO 15415, on the other hand, specifies quality requirements for 2D barcodes.

The key difference lies in their focus: AIM DPM deals with the physical marking process on objects, while ISO 15415 focuses on the print quality of 2D barcodes to ensure readability.

Yes, ISO barcode standards apply to both 1D and 2D barcodes.

ISO/IEC 15416 specifies quality requirements for 1D barcodes, while ISO/IEC 15415 does the same for 2D barcodes.

Not adhering to ISO standards reduces barcode readability, operational inefficiencies, increased data collection and inventory management errors, and potential non-compliance with regulatory requirements. This can result in delays, additional costs, and damage to business reputation.

Yes, the healthcare industry benefits from specific ISO standards, such as ISO/IEC 15418, which covers data syntax for unique identification and traceability. These standards address the unique needs of healthcare, ensuring the safety, traceability, and authenticity of pharmaceuticals and medical devices through secure barcode systems.

ISO standards are reviewed at least every five years to consider technological advancements, industry feedback, and evolving market needs. Revisions are made as necessary to ensure that the standards remain relevant and effective in promoting interoperability and quality in barcode systems worldwide.

ISO standards play a critical role in global trade and supply chain security by ensuring consistent barcode quality and interoperability across international borders. This facilitates efficient inventory management, tracking, and authentication of goods as they move through the global supply chain, reducing the risk of errors, fraud, and delays and enhancing overall supply chain security.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below