Weighing scales don’t work in isolation. Their accuracy depends on a reference weight called a calibration weight or a test weight.

This article explains the different types of test weights and the standards behind them.

Understanding these weights is essential if your operation depends on reliable mass data, whether for labelling, batching or shipping.

From E1 to M3, we outline what separates one class from another and how to choose the right one.

Calibration weights, also called test weights, are masses with a known and certified value. They serve as reference standards to verify, calibrate, and adjust weighing instruments, from laboratory balances to industrial scales and everything in between.

This comparison process confirms that the instruments produce accurate and reliable results. These weights form a cornerstone of measurement quality, connecting an instrument’s reading to an international standard through an unbroken chain of comparisons.

Test weights provide a trusted reference for comparison in a three-step process. This cycle confirms that a scale is fit for its purpose.

First is calibration. A certified weight is placed on a scale, and the scale’s reading is compared to the weight’s known mass value. The difference is the scale’s measurement error. At this stage, no changes are made to the instrument; the goal is to measure its performance.

Second is verification. This step confirms if the scale’s error is small enough for its intended job. It is a pass-or-fail check against a defined tolerance.

If the error is too large, the final step is adjustment.

The adjustment is a physical or electronic correction to bring the scale’s readings closer to the correct value. Another calibration should always follow an adjustment to verify that the fix was successful.

Test weights must conform to standards to be useful. These standards group weights into classes based on their tolerance, the maximum error a weight can have from its stated mass value.

A scale with high precision needs a test weight with a very small tolerance. The leading organisations that publish these standards are the OIML and ASTM International.

The International Organisation of Legal Metrology (OIML) publishes the recommendation OIML R 111.

This is the most widely used standard globally, especially across Europe, the United Kingdom, Australia, and New Zealand. It organises weights into classes of decreasing accuracy, from E1 (the most accurate) to M3 (the least accurate).

Class E1 and E2: These are high-precision weights. E1 weights are primary reference standards used to calibrate other weights. E2 weights, such as those in pharmaceutical labs, are also used as reference standards for calibrating high-sensitivity analytical balances. Both classes are typically made from high-quality stainless steel in a one-piece construction to improve stability.

Class F1 and F2: These are for precision balances, like those with a readability of 0.01 g or 0.001 g. They are common in laboratories for quality control. F2 weights are also used to verify high-value commercial sales, like those used to measure precious metals.

Class M1, M2, and M3: These weights have larger tolerances and are used for commercial and industrial scales (NIST Class III or IIII devices). M1 weights are used to test typical trade scales. M2 and M3 are for scales requiring less precision, such as in some retail settings or for rough weighing tasks.

OIML R 111 also lists rules for the weights’ physical properties, such as material, density, surface finish, and magnetism.

In the United States, laboratory weights are classified by the ASTM International standard E617. This system uses numbers, where a lower number means a smaller tolerance and higher accuracy.

ASTM Class 0, 1, 2, 3, 4: These are precision weights for laboratory work. Class 1 suits analytical balances, while Classes 2, 3, and 4 are for general lab use and calibrating moderate-precision scales. ASTM Class 1 is similar in tolerance to OIML Class E2 or F1.

ASTM Class 5, 6, 7: These are industrial weights with larger tolerances, comparable to OIML M-class weights. They are often made of cast iron and are used to test heavy-capacity scales like floor scales.

In the US, rules for scales used in commerce are set by the National Institute of Standards and Technology (NIST) in its Handbook 44.

NIST Class F was the standard for weights used by field inspectors to test commercial scales.

However, NIST has updated its policy. Since January 1, 2020, it has been recommended that no new Class F weights be used to test commercial scales.

Instead, NIST now recommends using weights that conform to ASTM E617 or OIML R111-1 standards, such as ASTM Class 6 or OIML Class M1, depending on the accuracy class of the scale being tested.

ASTM Class 6 or better. This change reflects that modern commercial scales have become more accurate and need better test weights. Existing Class F calibration weights can still be used if they are stable and verified, but only for testing and calibrating weighing devices classified as Class III, IIIL, or IIII, and scales without a designated accuracy class.

Both Australia and New Zealand align their national rules with the OIML framework.

Australia: The National Measurement Institute (NMI) oversees Australia’s measurement system. Weights used to verify scales for trade must be certified by the NMI or a licensed party and meet OIML class requirements. Typically, OIML Class M1 weights are used in the field.

New Zealand: The country’s Weights and Measures Act also follows OIML conventions for trade measurement. The Measurement Standards Laboratory (MSL) is the national body that maintains mass standards. All weights used for trade must be traceable, with calibration provided by MSL or a laboratory accredited by International Accreditation New Zealand (IANZ).

Accuracy, Precision, and Tolerance – How Are they Different?Accuracy describes how close a measurement is to the true value. For a scale, accuracy is its ability to show a reading that matches the known mass of a certified test weight. A scale’s accuracy is checked across its full capacity using a linearity test. Precision describes the repeatability of a measurement. It is a scale’s ability to give the same result every time the same weight is measured under the same conditions. A scale can be precise without being accurate (for example, giving the same wrong reading repeatedly). Precision is measured with a repeatability test. Tolerance, or Maximum Permissible Error (MPE), is the maximum amount a test weight’s actual mass is allowed to be different from its nominal value (the value printed on it). Each weight class, such as OIML F1 or ASTM Class 4, has a specific tolerance set by the standard. For example, a 100 g weight in OIML Class F1 is allowed a maximum error of ±0.5 milligrams from its stated value. A calibration weight is compliant if its error is within this tolerance. |

Standard Name | Brief | What Is Defined | Classes |

|---|---|---|---|

ASTM E617-23 Standard Specification for Laboratory Weights and Precision Mass Standards | Defines laboratory weight tolerances, traceability and performance requirements for classes 000-7. | Material (stainless steel, brass), density, magnetism, surface finish, geometry and mass values | Classes 000, 00, 0, 1, 2, 3, 4, 5, 6, 7 |

OIML R 111-1:2004 Metrological and Technical Requirements of Weights | International recommendation setting error limits and technical specs for legal-metrology weights. | Material (stainless steel, non-magnetic alloys), shape (cylindrical), surface finish, geometry and permissible errors | Classes E1, E2, F1, F2, M1, M1-2, M2, M2-3, M3 |

BS EN 45501:2015 Metrological Aspects of Non-Automatic Weighing Instruments | UK adoption of OIML R76-1 covering instrument requirements and referencing test-weight specs. | References OIML R 111-1 for test-weight material, shape, surface finish and error tolerances | Follows OIML classes: E1-M3 (via referenced R 111-1) |

EN 45501:2015 Metrological Aspects of Non-Automatic Weighing Instruments | EU harmonised standard aligning NAWI requirements with CE-marking and legal-metrology rules. | Refers to OIML R 111-1 for test-weight specs: material, geometry, surface finish and tolerances | Adopts OIML classes E1-M3 |

National Trade Measurement Regulations 2009 under National Measurement Act 1960 | Australia’s legal framework for trade-measurement masses and their use in commerce. | General reference to OIML classes; mandates use of weights made of stainless steel or brass, defined shapes and surface finish | References OIML R 111-1 classes E1-M3 for lab and trade use |

References OIML R 111-1 classes E1-M3 for lab and trade use | Sets legal requirements for verification, stamping and approval of trade weights. | Does not itself detail material or construction; refers to regulations that adopt OIML-based specifications for shape and finish | Implements OIML classes E1-M3 via secondary legislation |

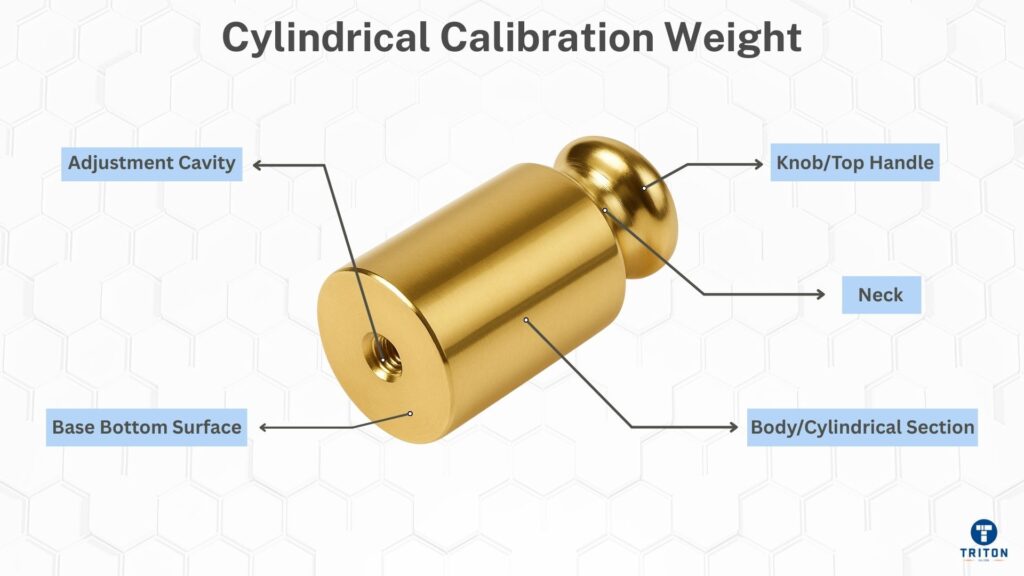

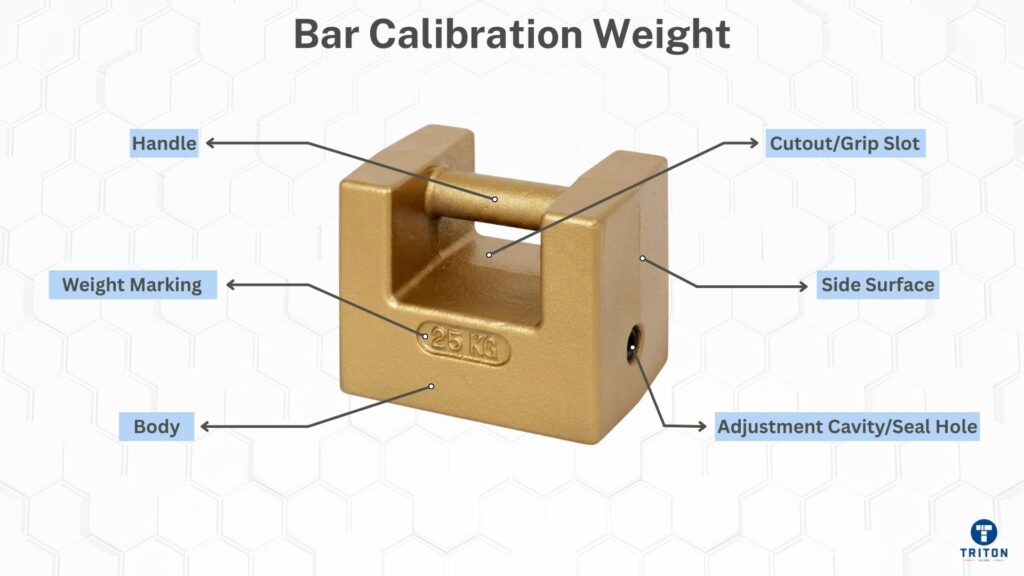

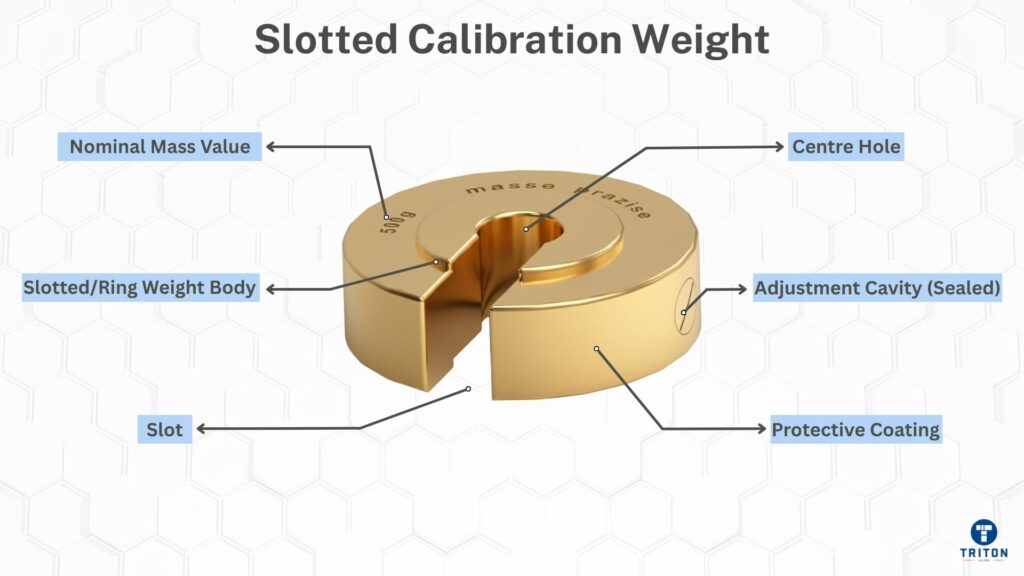

A calibration weight is a standard. For a standard to be trustworthy, it cannot change. A test weight’s form and material are therefore engineered to resist change.

Since a weight’s mass must remain constant, its material must resist mass-altering chemical changes like rust. Its density must also be stable, which makes the slight upward push from air buoyancy consistent and predictable.

Finally, the material cannot be magnetic. An electronic balance works by creating an electromagnetic force. An unwanted magnetic field from the weight itself adds a contaminating force, corrupting the measurement and making the result incorrect.

The physical design of a weight is shaped by its function, making it stable and easy to handle.

Test weights are used in any field where mass measurement is a quality, safety, or commerce factor. The class of weight and the strictness of the calibration schedule are directly related to the risk of the weighing application.

In the pharmaceutical industry, the risk of an incorrect weight is a matter of patient safety. Drug formulation depends on precise measurement of active pharmaceutical ingredients (APIs).

The United States Pharmacopoeia (USP) General Chapter <41> “Balances” therefore mandates rigorous testing with certified weights of defined tolerance. Consequently, labs routinely use high-precision OIML E2 or F1 weights for daily performance checks on analytical balances to satisfy USP and GMP requirements.

Australia’s Therapeutic Goods Administration (TGA) and New Zealand’s Medsafe enforce the PIC/S Guide to GMP, which likewise requires that balances be calibrated at defined intervals with certified, traceable weights of suitable accuracy-again typically OIML E2/F1-whose values are linked back to the national standards maintained by the National Measurement Institute (NMI) in Australia and the Measurement Standards Laboratory (MSL) in New Zealand.

The food industry relies on accurate weighing for quality control and to comply with trade laws. Any product sold by weight, from deli meats to packaged flour, must be weighed on a ” legal-for-trade ” scale.

In the United States, the scale’s design must be certified by the National Type Evaluation Program (NTEP) as meeting the rules of NIST Handbook 44.

In Australia, scales used for trade must be approved by the National Measurement Institute (NMI) under the National Measurement Act 1960 and the National Trade Measurement Regulations 2009. In New Zealand, the Weights and Measures Act 1987 mandates that any weighing equipment used for trade must be of an approved type and carry a mark of verification.

Businesses use certified M1 or M2 weights to check these scales regularly, avoiding fines and protecting their reputation. Calibrated scales are vital for recipe formulation in production, with records often forming part of a HACCP or ISO 22000 quality system.

In the chemical industry, precise weighing is important not only for quality but also for operational safety.

Furthermore, environmental rules, such as the US Environmental Protection Agency’s Resource Conservation and Recovery Act (RCRA) for managing hazardous waste, rely on accurate weight measurements to determine a facility’s legal status.

Across the manufacturing sector, test weights are used to maintain quality and efficiency. Quality Management Systems, most notably ISO 9001, mandate that all measuring equipment be controlled and calibrated on a schedule. Calibrating production scales with traceable test weights provides the objective evidence needed to show compliance with these quality standards.

In the aerospace industry, standards like AS9100 make traceable calibrations mandatory for tasks as important as weighing an aircraft to calculate its centre of gravity.

An error in weighing a chemical for an experiment can invalidate the results, wasting time and funding. For this reason, research laboratories rely on analytical and microbalances that are carefully calibrated with high-accuracy test weights to confirm that the foundational data for their discoveries is sound.

From international standards like OIML and ASTM to the specific grades of steel and iron used in their construction, it is clear that a test weight is a highly engineered tool. We have seen that its material, shape, and tolerance are carefully chosen to meet the demands of its application, whether to ensure regulatory compliance in pharmaceuticals or manage quality control in a factory.

Therefore, choosing the correct test weight is a foundation of any reliable weighing program and is an investment in measurement accuracy, data integrity, and professional quality.

To select the right certified weights for your specific application, explore the range at Triton Store.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below