RFID and barcodes have revolutionised the way businesses track and manage products. While both RFID and barcodes are asset-tracking technologies, they use different technologies and have their pros and cons.

This article aims to delve into the RFID versus barcode debate, comparing their fundamental differences, exploring practical applications, and shedding light on their impact across industries.

So, let’s get started.

RFID (abbreviation for Radio-Frequency Identification) is a technology that uses radio waves to identify and track tags. It is a form of wireless communication that enables data transmission from an RFID tag to an RFID reader device.

RFID system consists of three main components: RFID tag, RFID reader, and a backend system.

RFID tags are small electronic devices that consist of a microchip and an antenna. These tags are attached to or embedded within assets that need to be tracked. The microchip stores information about the asset, such as its identification number, serial number, etc. The scanning antenna allows the tag to communicate with RFID readers via radio waves.

RFID readers, also known as interrogators, are used to read the information stored on RFID tags.

Passive RFID tags use the energy of the radio waves emitted by the RFID reader to operate its microchip and send a signal back to the reader.

The backend system is responsible for processing and managing the data collected by the RFID readers. It includes software and databases that store and analyse the information received from the RFID tags.

This system can provide real-time tracking, inventory management, theft control, etc.

RFID systems offer many advantages. Some of these are:

A few RFID disadvantages are as follows:

A barcode is a machine-readable code. It comprises a series of black and white bars of varying widths and spacing enclosed within a square or rectangular frame. For a detailed overview of barcodes please read this blog what is a Barcode?

A barcode is designed to store data that can be easily decoded by a barcode scanner. Barcodes are often accompanied by printed numbers beneath the bars, for manual data entry in case of scanning failure.

Barcode technology uses a barcode scanner, which emits light onto the barcode and measures the reflected light. The process involves the following steps:

At Triton, we offer a wide range of high-quality barcode scanners from leading brands like Honeywell and Zebra.

Our inventory offers a diverse range of models to fit your specific requirements. From general scanner, mobile terminal, rugged scanner, 2D scanner, USB scanner, wireless scanner, Bluetooth scanner to fixed mount scanner and sensors, Triton has got you covered.

A few barcode advantages are:

A few limitations of barcode are:

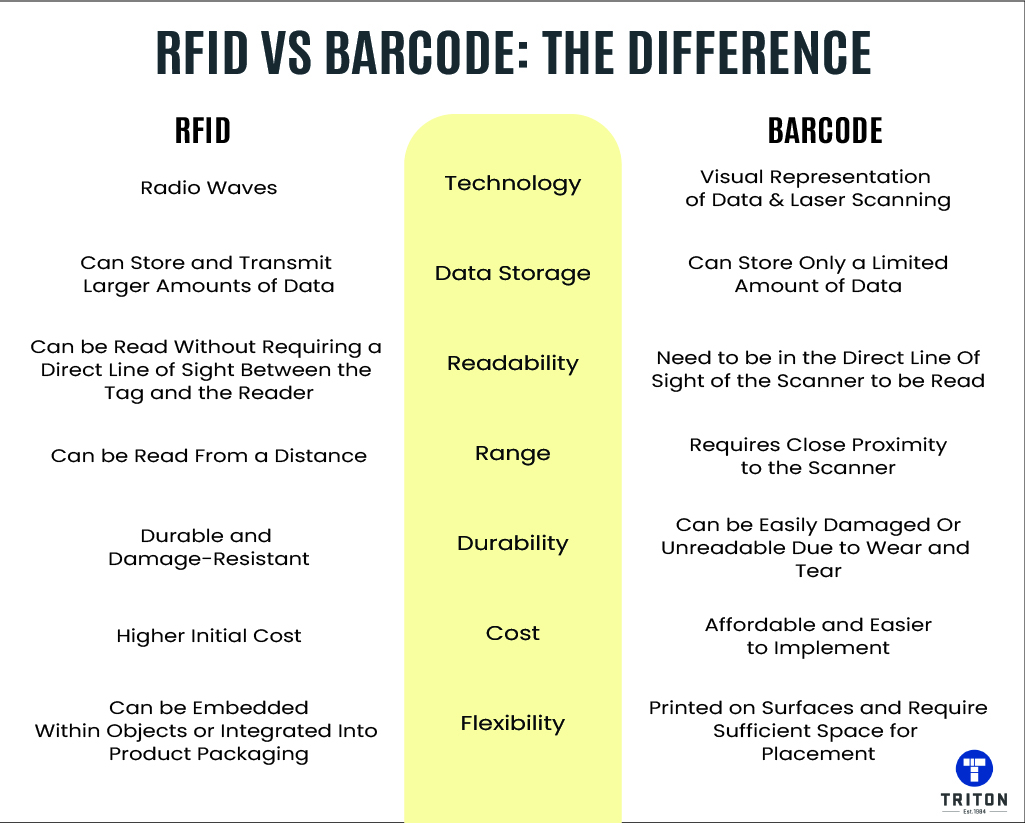

RFID and barcodes differ from each other on the following parameters:

RFID | Barcode | |

|---|---|---|

Technology | Uses radio frequency waves to communicate between RFID tags and readers.

| Rely on the visual representation of data using patterns of bars and spaces.

|

Data storage

| Can store and transmit larger amounts of data than barcodes. RFID tags can hold unique identifiers, additional product information, or even real-time sensor data.

| Stores only a limited amount of data, such as product identification numbers.

|

Readability | Can be read without requiring a direct line of sight between the tag and the reader.

| Needs to be in the direct line of sight of the scanner to be read.

|

Range | Can be read from a distance, depending on the frequency and power of the reader. This allows for quick and non-contact scanning of multiple items simultaneously. | Requires close proximity to the scanner and have a limited range for scanning.

|

Durability | More durable and damage-resistant than barcodes. They can withstand harsh environments (depending on their material), including exposure to water, dust, and extreme temperatures.

| Barcodes, particularly printed ones, can be easily damaged or unreadable due to wear and tear.

|

Cost | RFID technology typically has a higher initial cost compared to barcodes, including the cost of RFID tags and readers.

| More affordable and easier to implement.

|

Flexibility | Can be embedded within objects or integrated into product packaging, making them less visible and more discreet.

| Printed on surfaces and require sufficient space for placement.

|

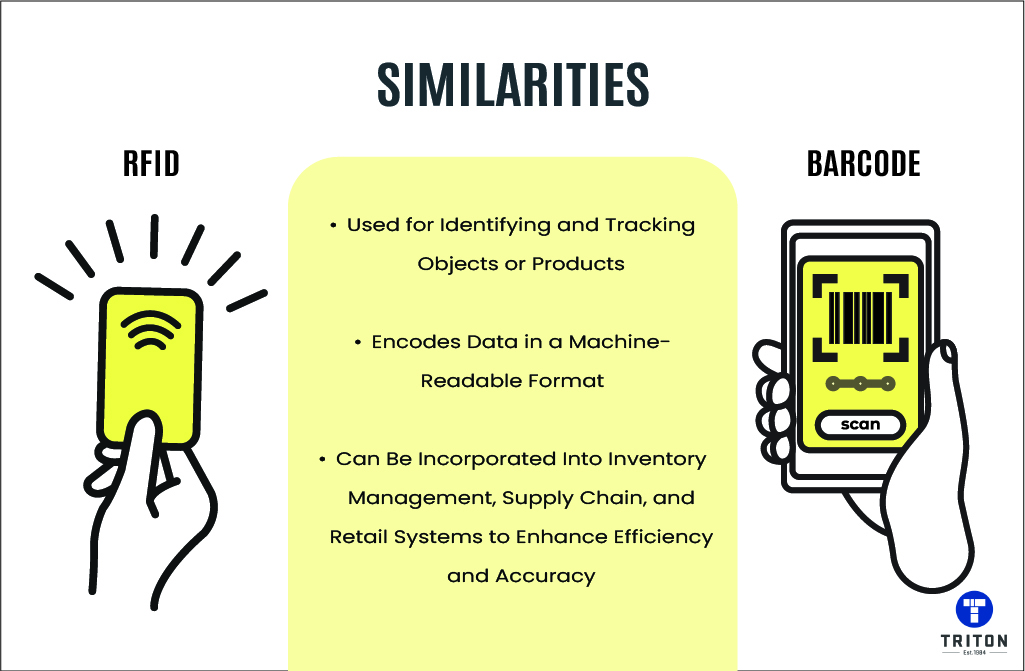

RFID (Radio Frequency Identification) and barcodes are different technologies but share some similarities in certain parameters:

In terms of raw speed, RFID is generally faster than barcodes.

With RFID, information can be read or written to a tag without the need for line-of-sight contact, as it uses radio waves to communicate. This means that multiple RFID tags can be read simultaneously, leading to faster and more efficient data capture.

For example, in a retail environment, RFID technology can enable faster inventory management and checkout processes than barcodes.

Barcodes, on the other hand, require a line-of-sight reading approach. Each barcode needs to be individually scanned by a barcode reader, which can take longer, especially when dealing with large quantities of items.

The choice between RFID (Radio Frequency Identification) and barcodes depends on the specific needs and requirements of the application.

Barcodes are generally more cost-effective and easier to integrate, while RFID offers advantages in terms of speed, range, and data capacity.

The choice depends on the application’s specific needs, such as the required reading range, data capacity, environmental conditions, and budget.

In conclusion, the comparison between RFID (Radio Frequency Identification) and barcodes reveals distinct differences and shared characteristics.

The choice between RFID and barcodes ultimately depends on specific requirements, industry demands, and budget considerations.

Understanding the strengths and limitations of each technology is essential for making an informed decision and leveraging the benefits they offer in various business contexts.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below