A thermal printer is a great investment for the business. However, like any other machinery, thermal printers require some upkeep to maintain their optimal performance.

Dust, debris, and even paper particles can build up inside the printer and cause problems like paper jams or reduced print quality. Moreover, these foreign particles will lead to costly repairs and reduce the printer’s lifespan in the long run.

Therefore, performing a routine cleaning of thermal label printers is best to avoid such future headaches.

As you read on, you will find different methods of cleaning thermal printers, thermal printheads, and platen rollers. You will also get some best practices for extending the life of thermal printers and printheads.

Let’s start with some precautions to take before cleaning thermal printers.

Here are a few things to keep in mind before starting the cleaning process.

Now that we know what precautions to take, let’s move on to cleaning thermal printers.

The following materials are required to clean the exterior of thermal printers.

Start by wiping the exterior body of the printer using a dry lint-free cloth. Wipe it down in gentle, circular motions until all dry dirt and dust are removed. Use a soft cleaning brush to dust off any dirt or debris from hard-to-reach areas like screw heads and connection ports.

If there are tough stains like sticker residue, dampen another lint-free cloth with some isopropyl alcohol or water and gently rub the affected area in a to-and-fro motion. Pour only a small amount of liquid on the cloth, so it doesn’t drip inside the printer and damage its electronic components.

Once all the stains are removed, go over the area with a dry lint-free cloth to wipe off the moisture.

After cleaning the body, move on to cleaning the control panel.

Use a soft brush to remove dry dust from the buttons and display screen. If there are any greasy fingerprints or smudges, dampen a lint-free cloth with some isopropyl alcohol or water and gently wipe them away. Again, ensure you don’t use too much liquid, as it can seep inside and damage the electronic components beneath the control panel.

Once you’re done cleaning, wipe the buttons and display screen with a dry lint-free cloth to remove the moisture.

Interior cleaning of thermal printers is a bit more delicate as we will deal with sensitive components like media hangers and sensors.

The following things are required to clean the interior.

Start by blowing off any dust or debris from the interior using canned compressed air. If you have a small anti-static vacuum cleaner, you can use that instead. Be careful not to use too much pressure or put the vacuum nozzle too close to printer components.

Once all the dust has been removed, wipe down all surfaces with a clean, lint-free cloth. Use cotton swabs for sensitive, difficult-to-reach places like printer sensors.

Never use any liquid, like water, inside the printer.

A thermal print head is the most important, delicate, and expensive component of direct thermal printers and thermal transfer printers.

Read our article on direct thermal vs thermal transfer printing to learn about the differences between the two print technologies.

Any damage to the print head will result in poorer print quality or, in worst-case scenarios, a complete replacement of the print head. Therefore, extra care must be taken when cleaning a print head.

There are four methods of cleaning a thermal print head.

Follow our thermal printhead care guide for best practices on maintaining a thermal printhead

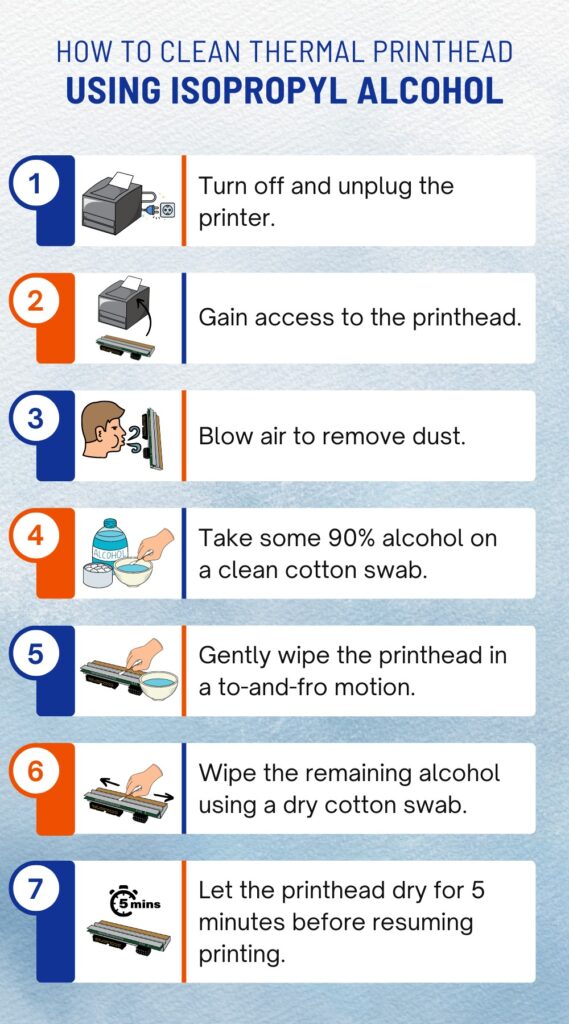

Step 1 – Turn off the printer and unplug it from the power source.

Step 2 – Pull the print head access door to access the thermal head.

Step 3 – Blow some air to remove dust or debris around the print head. You can also use a can of compressed air for this.

Step 4 – Pour a few drops of isopropyl alcohol onto a cotton swab.

Step 5 – Using the soaked cotton swab, wipe the surface of the thermal head in a to-and-fro motion. Run the swab along the entire length of the head. Apply firm but gentle pressure to ensure proper cleaning.

Step 6 – Wipe the head with a dry cotton swab to remove excess alcohol.

Step 7 – Allow the thermal head to dry for 5 minutes before closing the print head access door and plugging in the printer.

The isopropyl alcohol cleaning method is considered one of the safest and most effective ways to clean a thermal print head. It can be used regularly (like every week) to keep the print head clean and ensure high-quality printing.

Most printer manufacturers like Honeywell, Zebra, and TSC recommend using isopropyl alcohol for cleaning the printhead.

A cleaning card is a small, rectangular card made of a soft, lint-free material. It is slightly larger than a credit card and thinner than a business card. Cleaning cards come pre-saturated with isopropyl alcohol.

When a cleaning card is inserted into the printer, it runs through and comes in contact with the print head. The printer then moves the cleaning card repeatedly, ensuring that the entire print head is exposed to the cleaning card. This action transfers dust, debris, or buildup to the cleaning card, leaving the print head clean.

Moreover, as cleaning cards are moved through the printer multiple times, they also clean the platen roller. A clean platen roller ensures that print media moves smoothly and doesn’t get stuck in the printer.

Using a cleaning card may vary depending on your printer model. Therefore, please refer to your printer’s user manual for specific instructions.

Cleaning cards are an easy and effective way to clean a thermal printer without opening it up or coming into contact with the print head. However, cleaning cards can damage the print head and the platen roller if used frequently (like every two weeks).

We recommend using cleaning cards periodically, like once a month.

This method is highly recommended for card and badge printers.

A cleaning pen is a small, hand-held cylindrical device with a soft, absorbent felt tip. The tip of the cleaning pen is soaked in isopropyl alcohol.

Please ensure the cleaning pen contains 90% or higher isopropyl alcohol.

Here’s a step-by-step process on how to use cleaning pens to clean thermal printers.

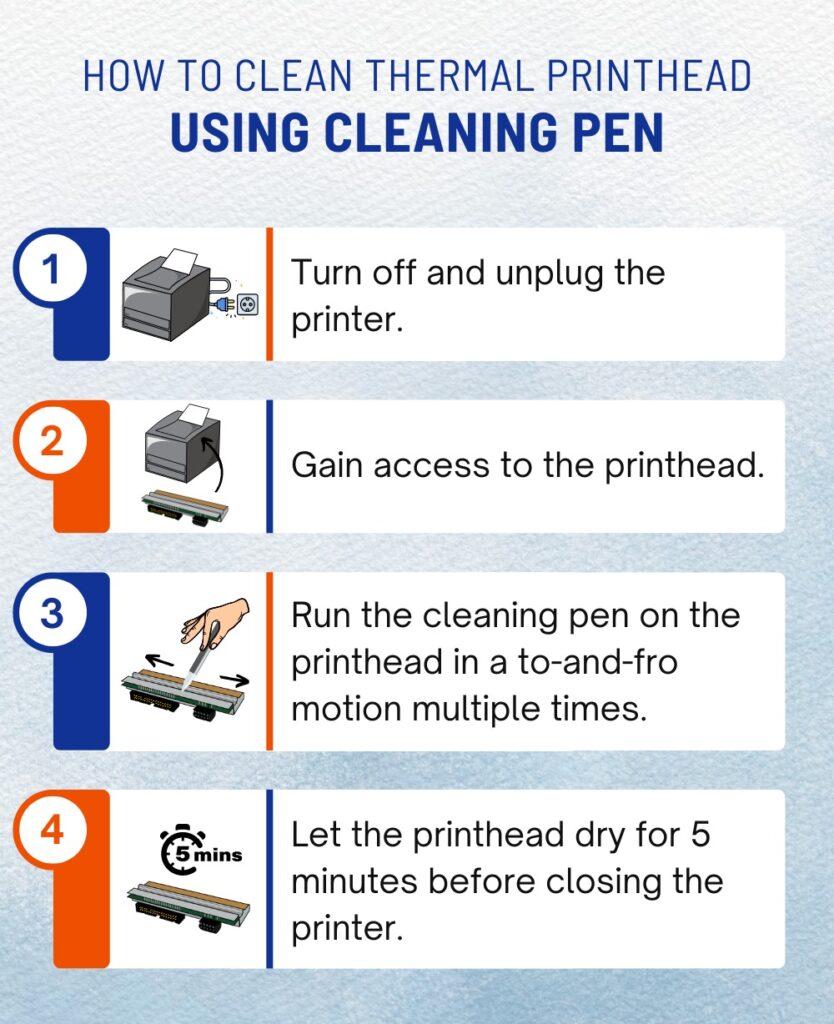

Step 1 – Turn off the printer and unplug it from the power source.

Step 2 – Lift the print head access door to access the thermal print head.

Step 3 – Run the cleaning pen along the entire length of the thermal print head multiple times. Apply gentle pressure to ensure that the felt tip comes in contact with the whole surface of the head.

Step 4 – Let the thermal print head air dry for about five minutes before closing the print head access door and plugging in the printer.

Cleaning pens can also be used to clean the platen roller. Simply run the cleaning pen along the entire length of the roller.

A cleaning pen will easily last for roughly 10-12 uses before it needs to be replaced. Here is a list of some reputable brands that offer cleaning pens.

Cleaning pens are safe and will not damage the print head or platen roller if used properly. They are recommended for all types of thermal printers.

Some thermal ribbons come with an attached cleaner strip located at the start of the ribbon roll. This strip is coated with a cleaning solution. When this cleaner strip comes in contact with the thermal print head, it removes the buildup or dirt present on the head.

Thermal ribbons with built-in cleaners are designed to remove dirt and dust from the print head every time a new ribbon is installed. These are perfect for those who forget to clean their printer regularly.

This method works with thermal transfer printers only. As direct thermal printers don’t use ribbons, they cannot take advantage of this cleaning method. To learn about the working of thermal printers, check out our article on how thermal printers work.

Platen roller cleaning is often overlooked, but it’s an important part of maintaining a thermal printer. A dirty platen roller can cause print quality issues like lines, smudges, or wrinkles.

We have divided the platen roller cleaning methods into two categories – Regular Cleaning and Deep Cleaning. The cleaning procedure will be determined by how dirty the roller is.

For a lightly soiled platen roller with visible dirt or debris, we recommend using the regular cleaning method.

For a heavily soiled platen with stickiness or caked-on dirt, we recommend using the deep cleaning method.

Regular cleaning methods include using isopropyl alcohol, cleaning cards, and cleaning pens.

Please use these cleaning techniques according to the instructions in the respective sections above.

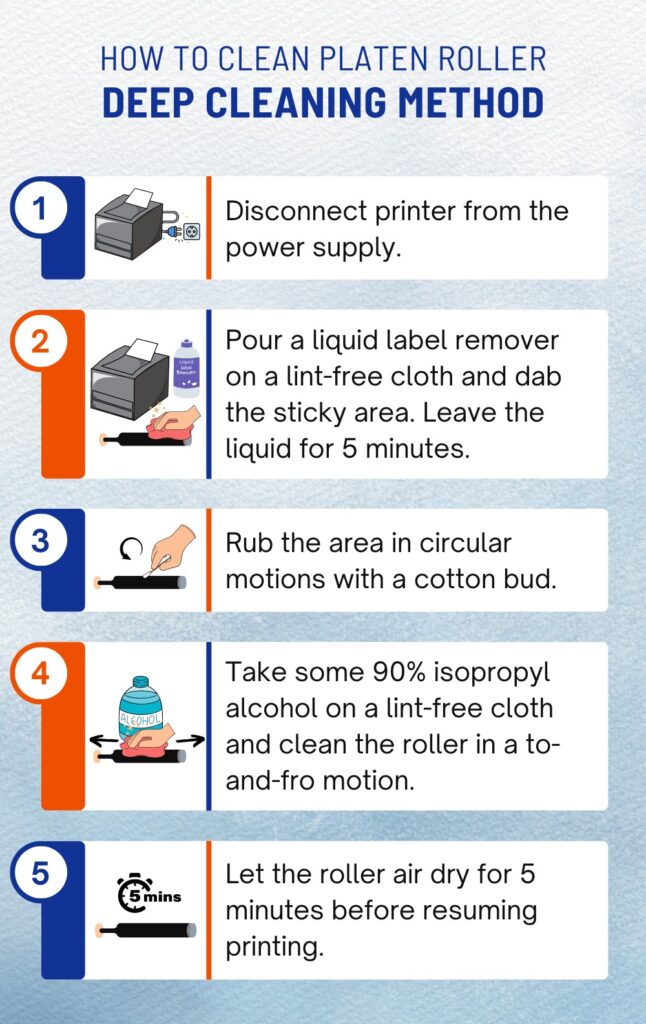

Step 1 – Turn off the printer and disconnect it from the power supply. If the printer is loaded with print media, remove it as well.

Step 2 – Pour a generous amount of liquid label remover into a clean, lint-free cloth. Dab the sticky area of the platen roller using this dampened cloth. Let the liquid sit for about five minutes. Make sure you dab the area lightly to avoid liquid label remover seeping into the thermal printer.

Step 3 – After five minutes, take a cotton bud and gently rub the area in a circular motion to loosen the adhesive.

Step 4 – Pour a small amount of isopropyl alcohol onto a clean, lint-free cloth. Rub the platen roller with this dampened cloth in a to-and-fro motion. This will remove the adhesive and other dirt from the platen roller. Make sure to rotate the roller while cleaning to cover the entire surface.

Step 5 – Allow the platen roller to air dry for about five minutes.

Repeat the process if the platen roller is still sticky.

This cleaning method should be performed with high caution as it has the potential to damage the platen roller. We recommend you seek professional help if the platen roller is severely sticky.

Here are a few tips that will help you extend the life of your thermal printer and its printhead. For an in-depth article see our Printhead Care Guide.

Regularly cleaning the thermal printer will prevent dirt and dust from entering the machine and damaging the print mechanism. Doing so will also ensure that the printer works optimally and produces high-quality prints.

As labels and ribbons come in direct contact with the printhead, it is important to use high-quality products to minimize wear and tear.

Using low-quality labels or ribbons will cause extra abrasion, adhesive bleeding, unfavorable perforations, and increased unwanted deposits, all leading to premature printhead malfunction.

Triton provides premium quality consumables at affordable prices to ensure optimal performance and longevity of your thermal printer. Click here to view our selection of print consumables.

Using original replacement parts is crucial for maintaining the printer’s performance and extending its lifespan.

Duplicate or counterfeit parts may not fit properly, leading to printing errors and malfunctions.

In our 40 years of business, we have seen many non-genuine parts cause problems. With that said we have scoured the market and found an excellent line of Datamax compatible printheads and Honeywell compatible printheads that are as good if not better than the OEM’s for a fraction of the cost. Beware though the quality of compatible printheads is rare and this particular line we supply is a rare exception!

Always refer to the printer manual for recommended replacement parts. Make sure to purchase original replacement parts from the manufacturer or authorised retailers like Triton. Authentic printer parts may cost a bit more, but they will save you money in the long run.

Triton offers a vast range of replacement parts at unmatchable prices. Click here to view our selection of accessories and spares.

Printer settings have a significant impact on printhead life. These print settings include print speed, temperature or darkness level, and printhead pressure.

Print speed is the rate at which the printhead moves during the printing process. As a general rule, the faster the print speed, the higher the wear and tear on the printhead.

But why do print speed settings affect printhead life?

When a faster print speed is selected, the printhead is forced to move more quickly. This rapid movement causes friction and heat buildup, leading to printhead damage.

To prolong the life of the printhead, we suggest printing at the slowest speed available unless there is a pressing time constraint.

Thermal print media rely on heat to activate the colorant and produce a print. Therefore, the more heat applied to the thermal print media, the darker and crisper the print.

However, constantly printing at high temperatures or darkness levels can cause damage to the printhead. This is because high temperatures lead to overheating and burning of the resistors on the printhead. High temperatures also increase the accumulation of print media deposits, leading to subpar print quality and early printhead failure.

To avoid such irreparable damages, we recommend using the thermal printer’s default temperature or darkness settings.

If, for some reason, you need darker prints, use the printer menu or drivers to change the darkness or temperature levels rather than modify the thermal printhead settings.

Printhead pressure determines the force at which the printhead is pressed against the thermal media during printing. It is responsible for producing clear, crisp, and darker prints.

Similar to temperature and darkness levels, too much pressure can damage the printhead. This is because excessive pressure will put added strain on the printhead. It also increases the friction and heat buildup as the printhead moves, reducing its lifespan.

Therefore, we suggest maintaining the default pressure settings or using the recommended settings as per the printer’s manual. If needed, make small incremental adjustments rather than drastically increasing the pressure.

Sharp tools like razor blades, cutters, or knives should never be used to remove labels. These tools can scratch, gouge, or cut the platen roller and printhead. Such damages are irreparable and lead to voids and imperfections in future prints.

Ribbon wrinkles refer to random diagonal lines that appear on printed labels. They are caused by various factors, such as.

If you notice ribbon wrinkles in your prints, check for the above causes and take corrective actions to fix them.

Media guides are adjustable arms that guide the label stock through the printer. They prevent misfeeds and ensure proper label alignment during printing.

However, leaving the media guides too far from the label margins can cause the media to move side to side. This will result in inaccurate printing, paper jams, delays, and additional expense due to the wastage of label roll.

Therefore, we recommend positioning the media guides as close to the label margins as possible. 1/16 inch gap is ideal for most label stocks. However, always refer to the printer manual or contact the manufacturer for specific media guide settings.

Most thermal printers feature a rugged and durable design, allowing them to handle various environments. However, exposing the printer to extreme temperatures can cause damage and affect its performance.

Check the operating condition range of your thermal printer and avoid exposing it to conditions outside of this range. Additionally, make sure the printer is not placed near heating or cooling vents, direct sunlight, or near heat sources like heaters or radiators.

As thermal printers are often used for industrial or commercial purposes, they are often misused and mishandled. They are also used for continuous printing without breaks in between.

Loose or missing components can result in printing errors, paper jams, and hindrances to proper printer function. Therefore, it is essential to regularly check for loose printer components and tighten them if necessary. These print components include media guides, supply spindles, printhead screws, and other removable parts.

We recommend checking all visible areas of the printer at least once a month.

Placing a thermal printer in a high-traffic area can increase the chances of it being mishandled or bumped into, causing damage. It can also lead to dust and debris accumulation on the printer and its components, leading to technical glitches.

We recommend keeping the printer in a designated work area with limited foot traffic. This will ensure proper handling and reduce accidents.

When not in use, turn off the printer and unplug it from its power source. Store it in a clean, dry area away from dust, moisture, and extreme temperatures. We also recommend covering the printer with a dust cover to protect it from dust accumulation.

We recommend setting up a maintenance contract with the manufacturer or authorized service providers for added protection and convenience. This will ensure regular printer check-ups, cleaning, and necessary repairs to keep it functioning at its best.

A thermal printhead is one of the most moving components that comes into direct contact with the printing media.

Over time, the printhead accumulates a lot of foreign particles like dirt & dust, adhesive residue, paper dust, and ink buildup. These particles clog the printhead, forcing it to work harder and potentially reducing its lifespan.

Therefore, cleaning the printhead prevents such buildups and keeps the printhead functioning properly.

No, you should never clean thermal printheads with water or solvents like nail polish remover. These substances do not evaporate quickly enough and can damage the resistors.

It is best to stick with 90% or more isopropyl alcohol for cleaning the printer and its components.

Here are common signs indicating that your thermal printer needs maintenance.

The time frame for cleaning a thermal printer or printhead depends on how often it is used and the type of environment it operates in (i.e., dusty or clean).

As a general rule, you should clean the printer and the printhead each time you replace a new roll of label or ribbon.

Thermal printers are expensive investments, and with proper cleaning and maintenance, they can last for many years. By following the cleaning methods and printer maintenance tips above, you can keep your thermal printer functioning at its best.

We hope this article has provided helpful information on maintaining your thermal printer.

If you’re having problems deciding on a thermal printer, our thermal printer buying guide can help. Or, simply check out the list of best thermal printers in the market today.

If you have any other questions regarding thermal printers, please feel free to contact us via the live chat widget below. We will be happy to assist you.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below