Non-impact printers have revolutionised the printing industry by providing a quiet and non-contact printing process. From text documents to photos, non-impact printers allow you to print quickly and efficiently without worrying about noisy machinery or paper jams.

In this article, we will talk about non-impact printers. We will discuss their various types, characteristics, advantages and disadvantages. We will also compare impact printers with non-impact printers.

Let’s get started.

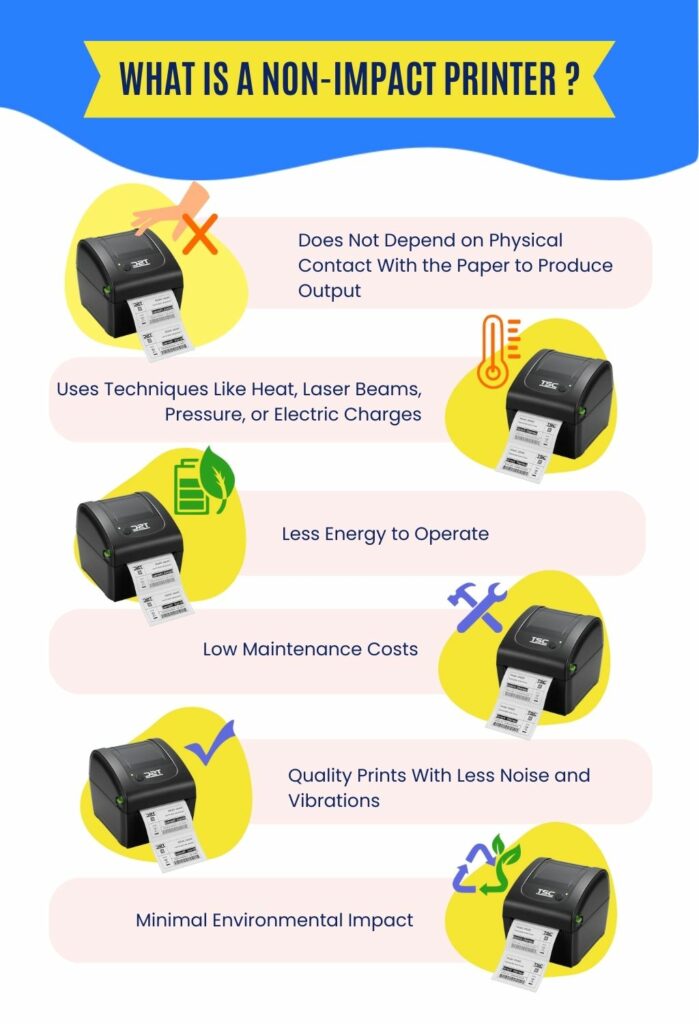

Non-impact printers are a type of printer which do not depend on direct physical contact with the paper to produce output. Unlike impact printers, they don’t need a print head or print hammer striking against a print medium to produce output.

Instead, non-impact printers use techniques such as heat, laser beams, pressure, or electric charges to create prints on print media. Non-impact printers are generally faster and quieter compared to other printer types.

Non-impact printers are now considered a staple of modern printing technology, as they require less energy to operate and produce quality prints with less noise and vibration. They are known for their low maintenance costs and minimal environmental impact.

Non-impact printers have also opened up the possibility of producing multiple print copies quickly, which was not possible using traditional printing technologies. They also offer high-quality resolution prints with vivid and crisp text and images.

Now that we have a basic idea about non-impact printers let’s see the different types of non-impact printers.

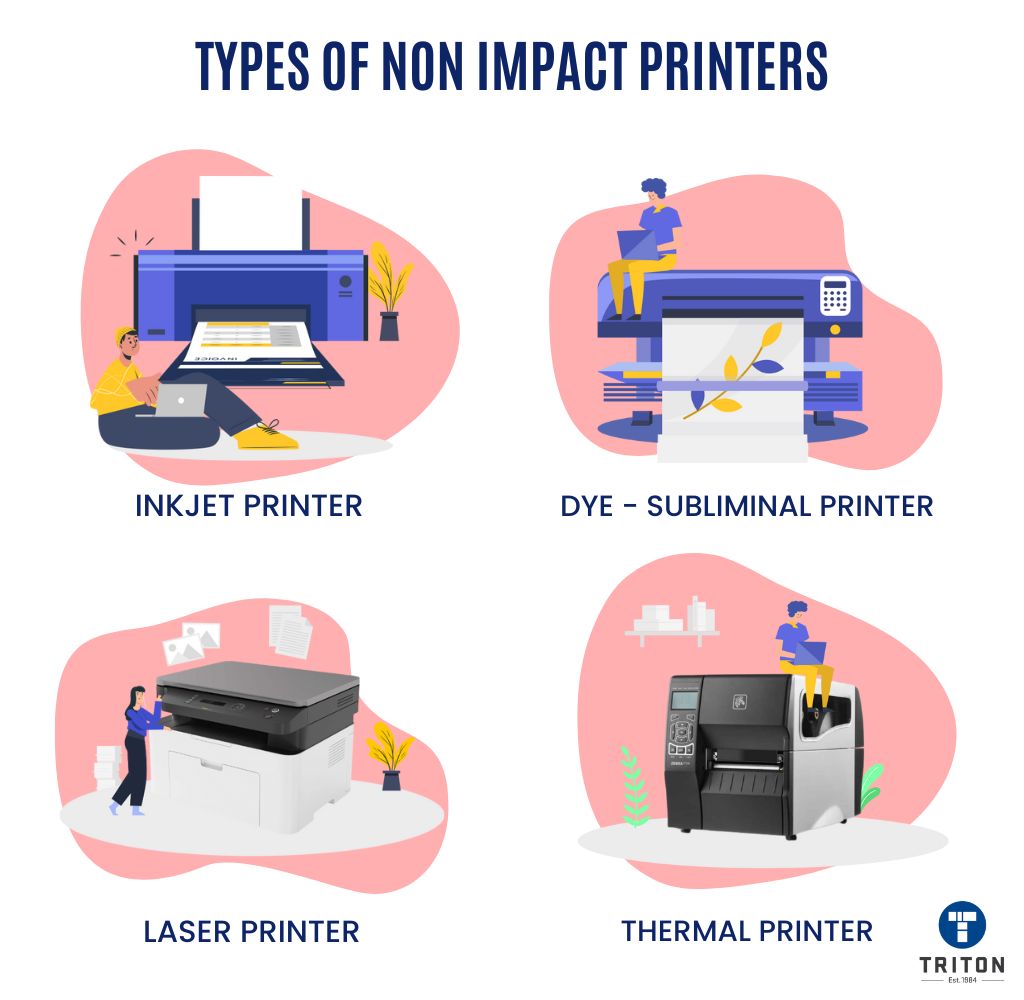

There are several types of non-impact printers which include –

Each non-impact printer type has its own unique advantages in terms of speed, reliability and cost efficiency. They use different printing mechanisms for creating prints and have different output quality levels to suit specific application needs.

Let’s have a look at each type of non-impact printer.

Laser printers are a type of non-impact printer that use laser LEDS to create an image.

Laser printers operate by creating an electrostatic image on a cylindrical-shaped roller known as the drum. This image is created by employing laser LEDs, which selectively charge the required areas on the drum’s surface.

Once the electrostatic image is formed, the drum is coated with a fine powder known as toner. The toner particles are attracted to the charged areas on the drum, adhering to the surface in the shape of the desired image or text.

Following this step, a sheet of paper is pressed against the drum. The toner particles are then transferred from the drum onto the paper. To ensure the toner stays in place and is firmly fixed onto the paper, a heat source is utilised. The heat melts the toner particles, fusing them to the paper’s surface and creating a clear, high-quality printed image or piece of text.

As you can see, the laser printing process relies on the intricate interaction of numerous components, such as lasers or LEDs, electrostatic charges, toner particles, and heat. This combination allows for impressively sharp image reproduction and crisp text, making laser printers popular for various printing needs.

Laser printers generate a significant amount of heat while working. This can reduce their lifespan and cause damage to the paper.

Inkjet printers are a type of non-impact printer that uses liquid ink to create prints. Inkjet printing functions by spraying fine droplets of liquid ink onto paper through minuscule nozzles.

There are several key mechanical components in an ink jet printer that work together to create the final print. These parts include ink cartridges, print heads, paper feed mechanisms, and control panels.

Ink cartridges are essential to an inkjet printer as they hold and supply the liquid ink required for printing. The printhead consists of a series of tiny nozzles that spray the ink onto the paper with precision. The print head moves across the paper horizontally, releasing ink droplets in a controlled pattern to form the desired image or text.

Inkjet printers are commonly used in home and small office environments to print text, photos, and other documents. This is because of their relatively low-cost printing with high-quality output. They also tend to be smaller and more compact, making them suitable for smaller areas.

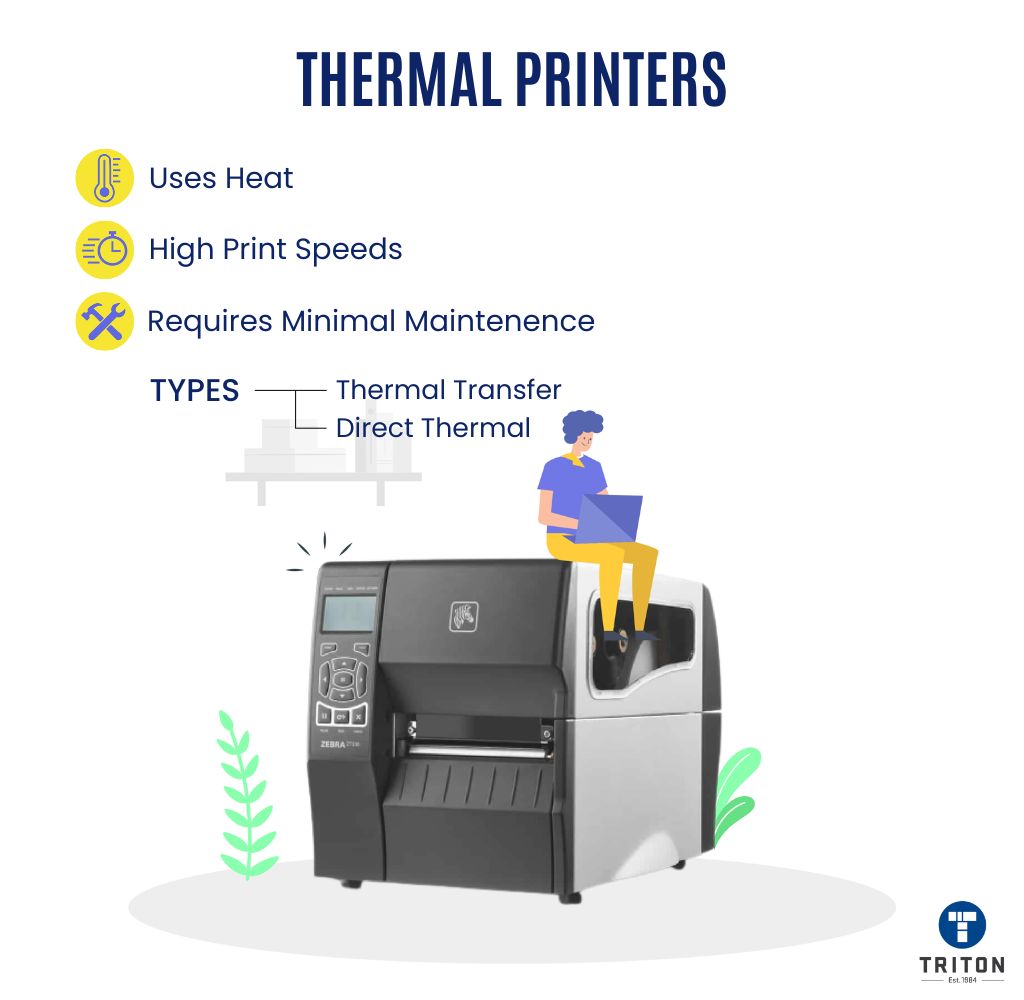

Thermal printers are non-impact printers that use heat to create prints. Thermal printers produce images by using heat-sensitive paper or ribbon, which is then heated and transferred to form a print.

The working of a thermal printer involves three main components: a print head, a platen (a rubber roller that feeds the paper), and a spring (applies pressure to hold the paper and printhead together).

Refer to our article on how a thermal printer work for a detailed explanation.

Thermal printers are generally used for printing small labels, receipts, tickets, and other shorter documents due to their high speed. Moreover, they require minimal maintenance and generate no sound when working.

There are two main types of thermal printers: Direct Thermal Printers and Thermal Transfer Printers.

In direct thermal printing, the thermal printer model uses thermal paper, which is coated with chemicals to change colour when heated. This heat-sensitive label receives heat from the thermal printhead, which darkens it, forming the desired print.

In thermal transfer printing, the thermal printer model uses a ribbon and print media to create desired prints. A ribbon is a thin film containing wax, resin, or a combination of both.

A thermal transfer printer first milts the ribbon and then transfers it onto the print media to create an image.

Triton is your comprehensive solution for all thermal printing requirements. We offer an extensive selection of direct thermal printers and thermal transfer printers from leading brands Honeywell, Zebra, and TSC. Our product lineup includes barcode label printers, desktop printers, and industrial printers, all available at highly competitive prices.

In addition to providing top-quality thermal printers, we also cater to your printer consumables needs with products such as thermal transfer ribbons, thermal labels, thermal carton labels, thermal carcase tags, and food-compliant thermal inserts. Our print consumables are of superior quality and are designed to provide sharp and vivid prints.

We understand the importance of maintaining your printers, and that’s why we also provide a wide range of spare printer parts and accessories, including thermal print heads, to keep your printers functioning at their best.

Our commitment to quality products and exceptional customer service makes Triton the perfect choice for all your thermal printing needs, whether for personal or business purposes. Choose Triton for a seamless and hassle-free printing experience today!

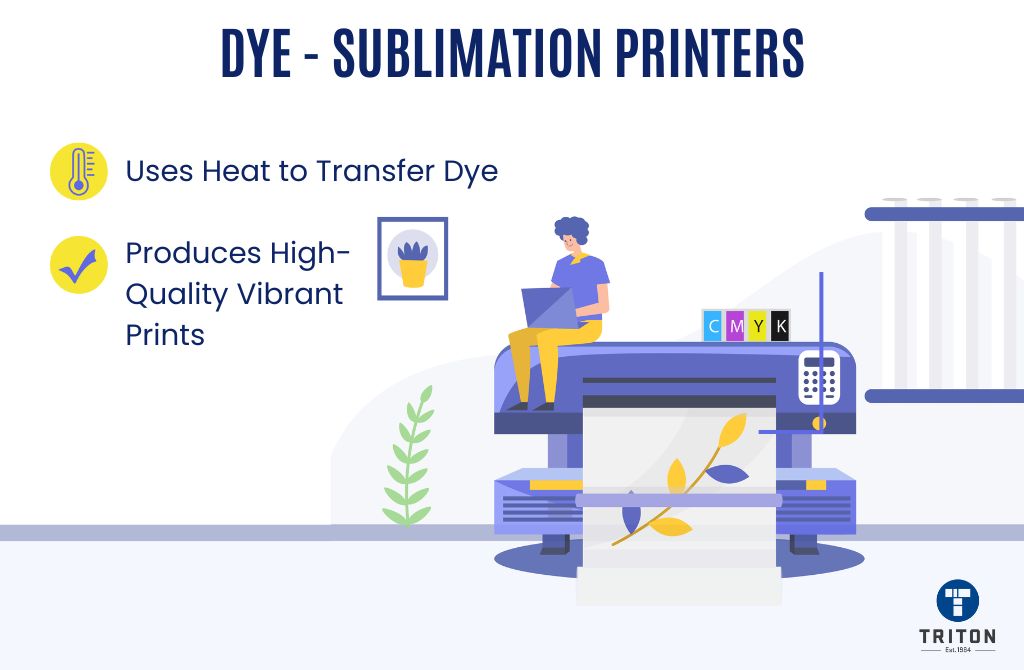

Dye-sublimation printers, also known as dye-sub printers or simply sublimation printers, are a type of printer that uses heat to transfer dye onto various materials such as paper, plastic, fabric, or metal.

The dye-sublimation printing process involves printing an image onto special transfer paper using a dye-sublimation ink ribbon. The transfer paper is then placed face-down on the material to be printed and heated with a roller or press.

As the transfer paper heats up, the ink sublimates into a gas, penetrating the material’s surface to create a permanent image.

Dye-sublimation printing produces high-quality images with vibrant colours that are resistant to fading and smudging. They are commonly used in applications such as photo printing, textile printing, and printing on mugs, keychains, etc.

Now that we have discussed the different types of non-impact printers let’s look at some general characteristics that all non-impact printers have in common.

Non-impact printers are much quieter than other printer types. This is because they do not have to physically contact the paper or any other material with a hammering device to create the desired printing result.

Quiet operation makes non-impact printers ideal for office environments where silence and efficiency are highly valued.

Non-impact printers offer significantly lower maintenance requirements than impact printers. Since they do not have any moving parts that come into direct contact with the paper, they have fewer mechanical failures and last a long time.

The risk of paper jams or other issues related to the misalignment of components is also very low in non-impact printers. Furthermore, these printers often include self-cleaning mechanisms like auto-nozzles and ink-drying systems. Such self-cleaning mechanisms help to reduce regular maintenance over time, saving you time and money.

Non-impact printers are usually much faster than impact printers when it comes to printing large volumes of documents. They are often equipped with features like automatic double-sided printing and document feeders that can further increase their output speed.

Non-impact printers produce high-quality prints with sharp details and vibrant colours. Both inkjet and laser printers can produce prints with resolutions of up to 1200 dpi (dots per inch), which results in extremely fine detail and clarity.

Non-impact printers use advanced technology to produce high-quality prints making them a bit expensive compared to other types of printers.

The initial cost of purchasing a non-impact printer is comparatively high. They also have ongoing costs for maintaining and replacing consumables such as toner or ink cartridges.

These costs can add up over time, making non-impact printers a more expensive option. Although their cost may be high, their reliability and long lifespan make them a worthwhile investment in the long run.

Non-impact printers can handle a wide range of media types and sizes, allowing users to create various printed materials for different purposes. This makes them very flexible and versatile for different printing needs.

Non-impact printers are also more flexible in terms of connectivity options. Most models come with built-in Wi-Fi, Bluetooth, USB, and Ethernet ports, making them easy to integrate into a network and various devices like computers, smartphones, and tablets.

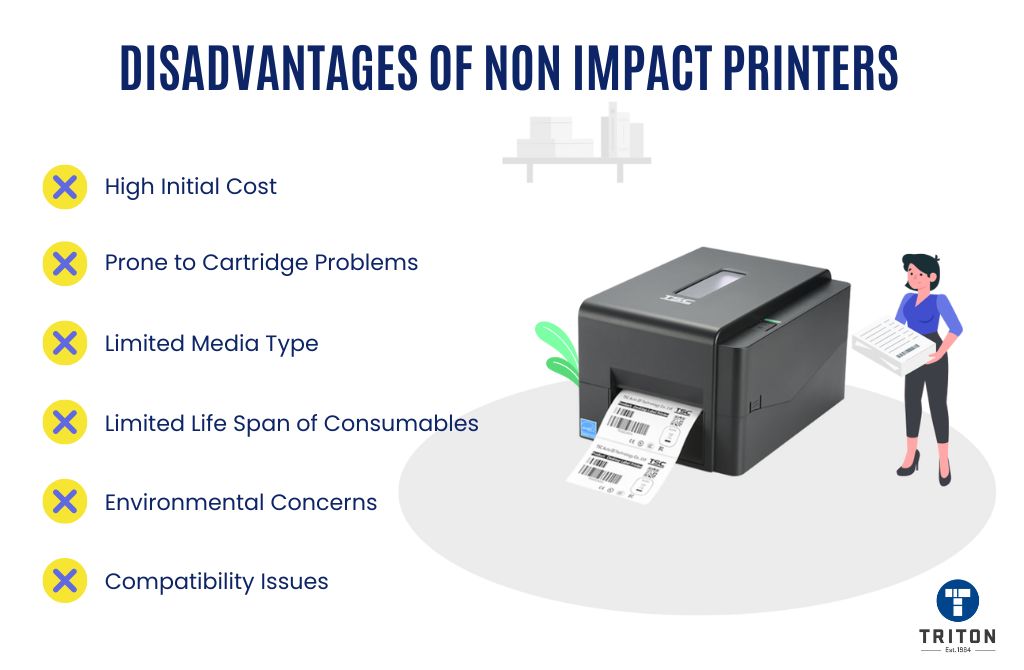

Here are some of the disadvantages associated with non-impact printers:

Non-impact printers often have a higher initial cost than other types of printers. This is due to their use of complex design advanced technologies.

Non-impact printers can be prone to cartridge problems. These problems range from poor print quality, clogged nozzles, or even complete failure.

Non-impact printers are limited in the types of media they can handle. These printers use either liquid ink or dry toner particles, which makes them unsuitable for materials with thick surfaces, such as cardstock or carbon paper.

Moreover, non-impact printers cannot print on transparencies. This is because they require a higher resolution that most non-impact printers cannot achieve.

Non-impact printers also generally don’t have the necessary power to print onto heavier media like cardstock or put a lot of pressure on the paper for embossing.

Non-impact printers are much more expensive to operate than their impact printer counterparts. This is largely due to the high costs of replacing inkjet cartridges and toner cartridges.

The cost of these print consumables can add up quickly and lead to higher per-page costs over time when compared with impact printers that use ribbons instead of cartridges.

In addition to the cost of purchasing new cartridges, there are environmental and waste disposal costs associated with appropriately disposing of the old cartridge.

Non-impact printers can have many negative environmental impacts when not used and disposed of responsibly.

From an energy consumption standpoint, non-impact printers require more electricity than impact printers.

The materials used in constructing non-impact printers, including plastic and metals, can be difficult or impossible to recycle. There are high chances for these materials to end up in landfills or other areas, where they can release toxins into the environment and take years to break down.

Inkjet printers, in particular, can generate highly hazardous waste. These hazardous chemicals released contain heavy metals such as lead, mercury, and cobalt – all of which can be harmful to both humans and the environment if released into the air or soil. Inkjet printers also produce volatile organic compounds (VOC), which are harmful.

Moreover, some types of ink used in non-impact printers contain toxic or carcinogenic substances when inhaled and can cause skin irritations or allergic reactions if touched.

To ensure minimal environmental impact from these devices, users should consider purchasing Energy Star-certified models. These models consume less electricity and use recycled materials in their construction.

Consumers should also pay attention to the materials used in their printer consumables and take steps to dispose of them responsibly.

Non-impact printers have a number of compatibility issues when certain software and hardware are used together. It is also seen that additional software will be needed for some functions of the printer to work.

Non-impact printers also face connectivity issues. Wireless signals can be interfered with due to other electronic devices nearby.

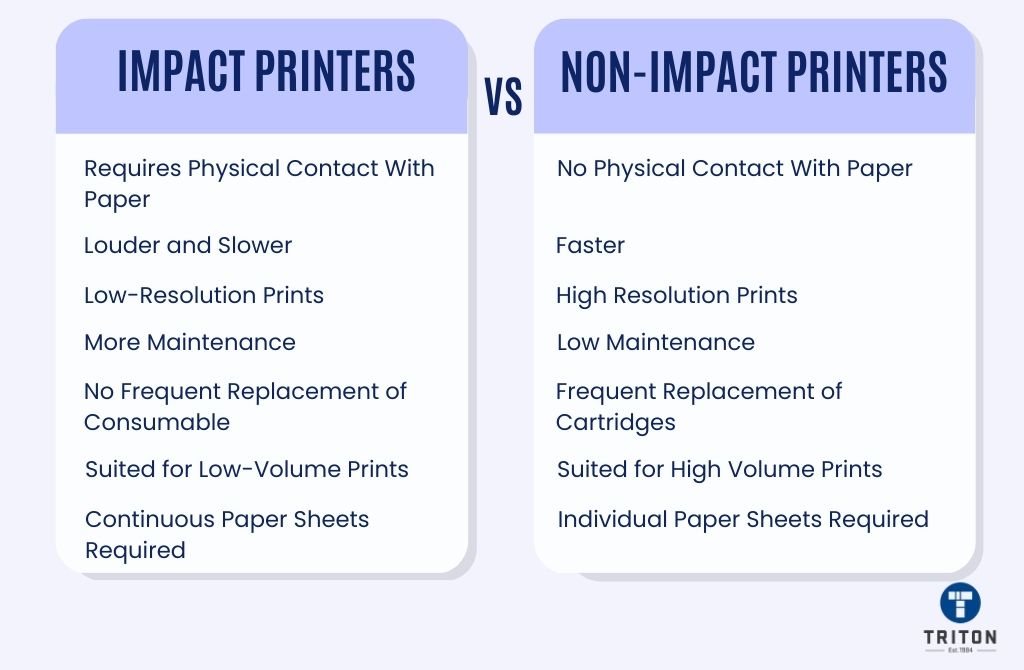

Impact printers are a type of printer that uses physical contact to create output. Unlike non-impact printers, they require a print head striking against an ink ribbon or another surface to produce output.

There are mainly three types of impact printers.

Let’s have a look at the major differences between impact and non-impact printers.

Impact Printers | Non-Impact Printers |

|---|---|

Needs physical contact with the paper to print

| No need for physical contact with the paper

|

Louder and slower

| Fast compared to impact printers

|

Low-resolution and low-quality prints

| High resolution and printing quality

|

Require more maintenance

| Low maintenance

|

No need for frequent replacement of consumables

| Frequent replacement of cartridges

|

Suited for low-volume prints with text and simple graphics

| Suited for large-volume prints requiring high resolutions

|

Require continuous paper sheets

| Require individual paper sheets

|

Non-impact printers are an excellent choice for applications that require high-resolution printing and minimal noise. However, they come with some drawbacks, such as compatibility issues, connectivity problems, and the need for frequent replacement of consumables like toner cartridges or inkjet cartridges.

It is important to consider your specific needs when choosing a non-impact printer to ensure you get the best results from your prints.

We hope this blog covers all the information you need about non impact printers.

Thanks for reading!

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below