In many industrial settings, labels have to endure very tough conditions. They must keep important information—such as product identification, safety notices, and tracking codes—clear and readable throughout the product’s lifecycle. Synthetic labels excel in these situations.

They stand up to moisture, chemicals, abrasion, UV light, and extreme temperatures. This resilience is especially important in industries where product safety and adherence to regulations are vital.

By contrast, paper labels may look nice and are often affordable for mild conditions, but they tend to fail when exposed to demanding environments. Meanwhile, more advanced options—such as RFID tags—offer improved tracking but can be expensive and technically complex.

In this guide, we will look at how synthetic labels fit into the broader labeling landscape. We will consider their performance, role in compliance, environmental impact, and the technology trends shaping their future.

The global market for synthetic labels has shown steady growth over the past few years. In 2023, it was valued at around $2.6 billion and is expected to reach roughly $4.9 billion by 2032. That comes out to a compound annual growth rate (CAGR) of about 7.1%. One major driver behind this steady rise is the growing demand for labels that can handle challenging environmental stresses.

Major companies in this space include Avery Dennison, CCL Industries, UPM Raflatac, 3M Company, and Lintec. They invest heavily in research and development to boost both the performance and the eco-friendliness of synthetic labels, meeting the changing demands of customers around the world.

Different types of synthetic labels are designed for specific industrial applications. Each material has unique properties that determine its suitability for various environments.

Polyester labels are highly durable and resistant to chemicals, heat, abrasion, and UV exposure. They are commonly used in automotive, electronics, and industrial equipment, where labels must withstand extreme temperatures and harsh handling.

PET labels maintain print clarity and adhesion over time, making them ideal for long-term asset tagging and compliance labels in demanding settings.

Polypropylene labels provide a balance between durability and flexibility. They resist water, oil, and mild chemicals, though they are less heat-resistant than polyester.

PP labels are widely used in the food & beverage, personal care, and retail packaging industries. Their semi-rigid structure makes them a good choice for applications where the label needs to conform to curved or squeezable surfaces without breaking.

Polyethylene labels are softer and more flexible than PET or PP, making them suitable for squeeze bottles, flexible packaging, and curved containers. They are commonly used in pharmaceuticals, cosmetics, and chemical packaging, where resistance to moisture and mild chemicals is essential.

PE labels are often chosen for their adaptability to flexible product packaging without compromising durability.

Vinyl labels are strong, weatherproof, and UV-resistant, making them ideal for outdoor signage, safety labels, and industrial warnings. They maintain readability even under prolonged sun exposure and extreme weather conditions.

However, due to environmental concerns over PVC plastics, they are being phased out in some regions in favour of more sustainable alternatives.

Polyimide labels are designed for extreme heat resistance, capable of withstanding temperatures over 300°C. These labels are widely used in electronics, aerospace, and high-temperature manufacturing. They are essential in printed circuit board (PCB) production, where labels must endure soldering and reflow processes without degrading.

Security labels are designed to prevent counterfeiting and unauthorised tampering. These include void labels, destructible films, and holographic labels, which show visible signs of interference when removed. They are widely used in pharmaceuticals, high-value consumer goods, and brand protection.

Tamper-evident labels help ensure product authenticity and regulatory compliance in industries where safety and security are critical.

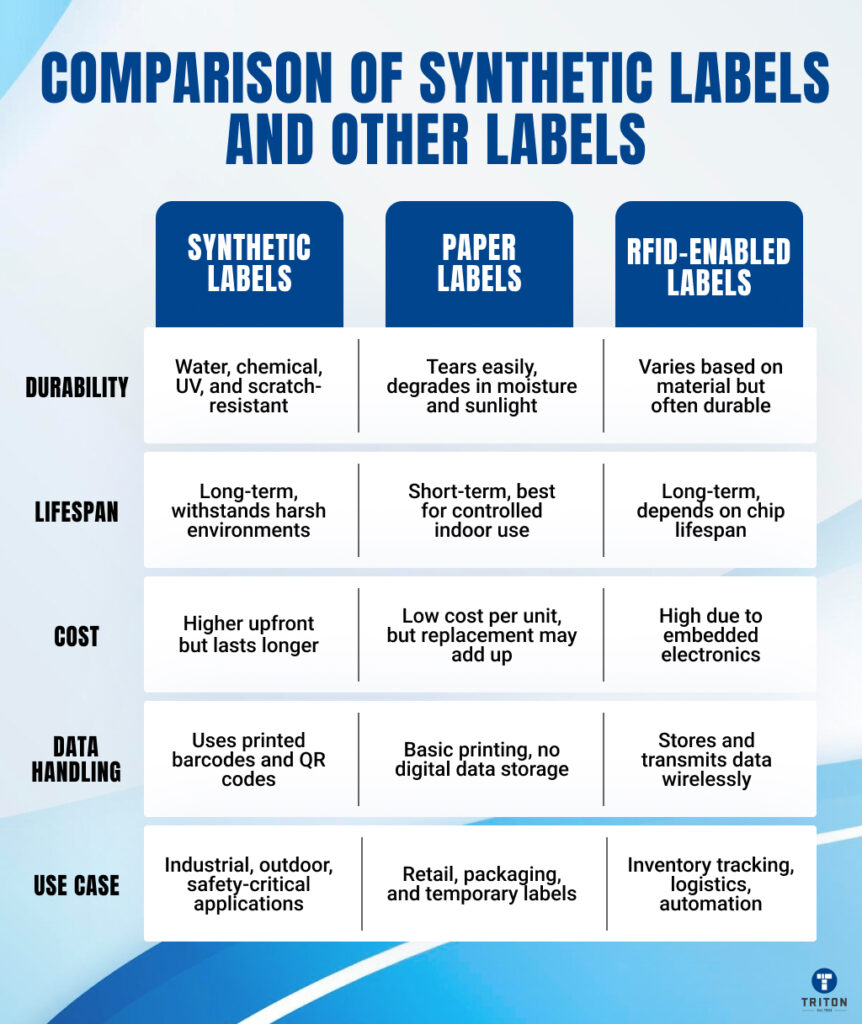

Durability & Longevity

Cost and Aesthetics

Data Capture and Tracking

Cost and Complexity

In short, paper labels may suffice when conditions are mild, and RFID tags deliver superior tracking but at a higher price. Synthetic labels often strike the best balance between cost, durability, and reliable performance. They also work well alongside RFID for businesses that want both durability and next-level traceability.

Regulatory requirements are strict in sectors like food, healthcare, and chemicals, where label failure can lead to serious risks.

Material Safety: Adhesives and coatings on synthetic labels for food packaging must be food-grade. They must comply with regulations like FDA’s 21 CFR §175.105, EU standards, and Food Standards Australia New Zealand (FSANZ) requirements.

Durability: Nutritional facts, ingredient lists, and allergy details must remain intact throughout the product’s shelf life, even under cold or moist conditions.

Legibility and Stability: Labels must stay clear through manufacturing, sterilisation, and distribution. They must comply with FDA regulations, Good Manufacturing Practices (GMP), and standards like ISO 15223–1 and ISO 11607–1. In Australia, labels must meet the Therapeutic Goods Administration (TGA) labelling requirements under the Therapeutic Goods Order (TGO) No. 91 and 92.

Traceability: Regulations require drugs and devices to be tracked via unique codes or barcodes that remain readable over time. Synthetic labels provide the reliability needed for compliance with these rules.

Hazard Communication: Labels must display hazard symbols and safety data in line with the Globally Harmonised System (GHS) and regulations like OSHA’s Hazard Communication Standard. In Australia, labels must follow Work Health and Safety (WHS) regulations and the Australian Code for the Transport of Dangerous Goods by Road & Rail (ADG Code).

Marine and Industrial Standards: For chemicals shipped across oceans, labels may need to meet British Standard (BS) 5609 to ensure they can endure prolonged exposure to seawater and extreme conditions. The UK’s Classification, Labelling and Packaging (CLP) Regulation, which aligns with GHS, applies similar standards (CLP Regulation).

Because of their durability, synthetic labels are often the safest choice where meeting these regulations is non-negotiable.

Synthetic labels offer excellent performance, but their environmental impact is a growing concern. Below are the main sustainability issues and how the industry is adapting.

Since most synthetic labels are made from plastic, they do not break down like paper. They can also interfere with recycling if they are not designed with disposal in mind. The adhesives and coatings may add another layer of complexity.

The labelling industry is tackling these challenges in several ways:

Governments are pushing businesses to reduce plastic waste and improve recyclability. Buyers now consider both performance and environmental impact when choosing labels.

New developments in labelling are turning synthetic labels into “smart” solutions that do more than just give basic information.

Smart labels merge synthetic materials with embedded digital tech:

Digital printing has brought major changes to the label industry:

Material science research keeps improving synthetic label formulas:

All these new technologies make synthetic labels more capable, more efficient, and more interactive, opening up fresh ways to streamline operations and connect with customers.

Synthetic labels play a key role in industrial and commercial applications where toughness, compliance, and reliability are essential. They stay legible and intact in settings that involve chemicals, extreme temperatures, or other challenging factors.

Paper labels still have their place in low-risk, short-term uses, but synthetic labels shine where a label absolutely must not fail.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below