Inkjet marking is a printing method that sprays tiny drops of ink to print letters, numbers, barcodes, logos, and QR codes on products. Industries like packaging, pharmaceuticals, and electronics use this method daily. Inkjet marking helps businesses add lot codes, serial numbers, and essential data quickly and easily.

This article explains how inkjet marking works, the different types, key uses, benefits, and how to choose the right system.

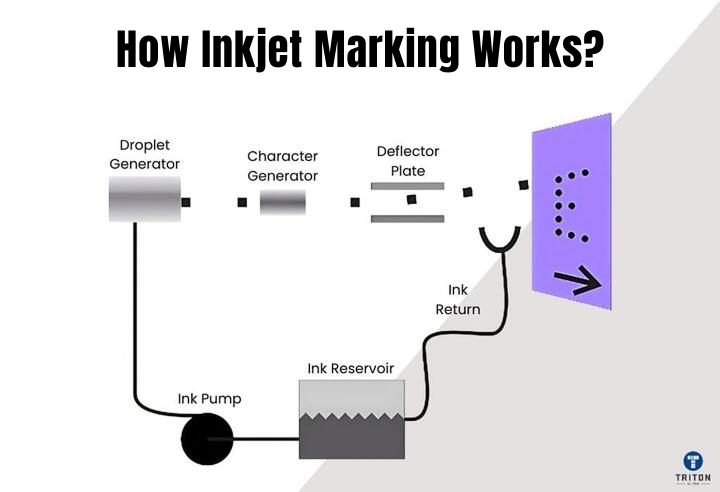

Inkjet marking systems spray tiny droplets of ink onto surfaces without touching them. Ink flows from cartridges or tanks through small nozzles. Electric signals cause droplets to leave the nozzle at high speeds, creating printed text or codes. This non-contact method protects products and ensures high-quality printing.

Inkjet marking is simple, straightforward, and fast. It is used for printing important data like date codes or product batch numbers.

Inkjet printing often prints detailed images or colourful graphics on paper, labels, or textiles. Inkjet marking typically prints small, clear characters quickly, while inkjet printing is used for high-resolution, colourful images.

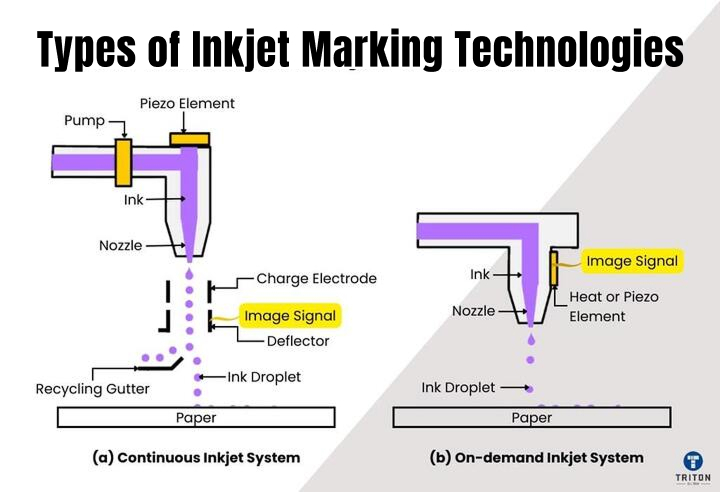

CIJ printers spray ink in a constant stream. Tiny droplets pass through electric fields that direct them onto the product. These machines print very fast, which is ideal for production lines with high demand. They print well on non-porous substrates like metal, glass, or plastic. But they need regular maintenance to avoid clogging.

DOD printers spray ink only when needed, providing more precise control.

TIJ printers heat the ink to create tiny bubbles. These bubbles force droplets out, forming clear, precise marks. They work great for printing barcodes, pharmaceutical packaging, or serial numbers. TIJ systems are easy to maintain and perfect for high-resolution printing.

Piezoelectric printers use electric currents to flex a nozzle, pushing ink droplets out. They print on many substrates, including plastics, paper, and cardboard boxes.

Piezoelectric inkjet markers offer flexibility and produce high-quality results for larger characters, logos, or labels.

Inkjet marking is vital for packaging operations. Companies print lot codes, expiry dates, and batch numbers on boxes, labels, bottles, and bags. Inkjet systems ensure these marks are clear, readable, and quick to print.

Electronics makers use inkjet marking for small, detailed marks on printed circuit boards (PCBs). Automotive factories print serial numbers and traceability codes on parts. High-quality marks help track items efficiently through operations.

Inkjet marking is widely used in pharmaceutical packaging. Companies must print clear codes on medicines to follow strict regulations. These codes include serial numbers, expiry dates, and batch numbers.

The codes allow companies to track medicines from factories to stores. Clear tracking protects patient safety.

Inkjet marking is very efficient, and high-speed printing matches production lines. It offers flexibility because systems quickly switch between different codes and data.

Companies save money since inkjet marking systems usually have lower costs than other marking solutions.

Because it is non-contact printing it does not damage delicate items and since it uses the inkjet technology, it produces high quality prints.

Selecting the right inkjet marking system depends on several factors. First, consider the materials you will mark. Examples include glass, plastics, metals, and paper. Next, choose an ink type suitable for your surface.

Solvent-based inks dry quickly and stick to non-porous surfaces like plastic or metal. UV-curable inks dry under UV light and leave marks that last longer on many materials. Also, make sure the system fits your working environment. Check if regular maintenance is easy to perform. These factors help you pick a system that meets your exact needs.

Inkjet marking does not work well on every type of surface.

It has difficulty marking oily metals, surfaces coated with lubricants, or hydrophobic plastics that repel water-based inks. Materials like Teflon present unique challenges since standard inks rarely adhere effectively.

Continuous Inkjet (CIJ) systems often face clogging issues due to dried ink deposits in nozzles, requiring frequent maintenance to remain operational.

Ink drying speed also varies depending on the ink formulation, substrate type, and environmental conditions. Slow-drying inks disrupt production speeds by forcing longer intervals between printing and handling products.

Humidity, temperature, and exposure to dust also affect reliability and print quality.

Choosing special inks, like solvent-based inks for non-porous surfaces or UV-curable inks for fast and reliable curing, overcomes the above mentioned limitations.

Limitation | Solution |

|---|---|

Poor adhesion on oily or hydrophobic surfaces | Solvent-based inks (e.g., MEK inks by Videojet, Markem-Imaje 5150) or UV-curable inks (e.g., Kao Collins UV-Curable Ink)

|

Difficulty marking Teflon and similar substrates | Specialized solvent-based inks designed for difficult surfaces (e.g., Videojet V421-D ink, Markem-Imaje 5199 ink) |

Frequent clogging in Continuous Inkjet (CIJ) systems | Automated cleaning CIJ systems (e.g., Domino Ax-Series) and recirculating printheads (e.g., Xaar TF Technology) |

Slow drying inks affecting production speed | Fast-drying solvent inks (e.g., Videojet Fast Dry MEK Ink, Domino BK651), or instant-curing UV inks (e.g., Kao Collins LED-curable ink) |

Sensitivity to temperature and humidity | Robust, stable formulation inks (e.g., HP 2580 Solvent Ink), climate-controlled printing environments |

New printhead technologies from manufacturers like Xaar and HP are improving print speed and reliability. For instance, Xaar’s recirculating printhead design helps prevent ink clogs, increases operational uptime and reduces maintenance.

HP’s thermal inkjet (TIJ) technology now achieves higher resolutions and is better at printing small text, QR codes, and barcodes.

These advancements help companies improve productivity, reduce operating costs, and decrease environmental impact.

As these trends continue, inkjet marking will become more efficient, reliable, and widely used across industries.

Inkjet marking is reliable for precise, fast printing across industries. Visit the Triton Store for the best inkjet marking solutions for your business needs.

We offer various printing solutions, including barcode generators, QR code generators, and advanced marking systems for diverse materials and industries.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below