Static cling stickers are printed graphics on a flexible plastic film that hold to smooth surfaces without adhesive. Instead of glue, they rely on physical attraction between the film and the surface.

These stickers come with a backing sheet, known as a release liner, which protects the cling side until application.

They are commonly used in retail displays, warehouse labelling, and logistics operations. Clings perform best on glass, metal, or glossy plastic and can be removed and reused if kept clean.

This article explains how static cling stickers work and why they matter when choosing labelling or signage solutions.

Static cling stickers do not rely primarily on static electricity, despite the name.

Although they may carry a minor static charge when peeled from the liner, this short-lived effect plays only a minor role in adhesion.

The actual sticking force comes from a physical interaction called van der Waals forces.

These weak molecular attractions occur when two smooth surfaces come into very close contact. The molecules on both surfaces develop temporary, opposite charges that attract one another. While each attraction is small, the combined effect across the entire surface holds the cling firmly.

Both surfaces must be clean, smooth, and non-porous for van der Waals forces to work well. Glass is ideal because it allows complete contact. Dust, texture, or moisture reduces the contact area and weakens the bond.

This explains why static cling sticks to windows but not to materials like cardboard or fabric.

Cling films are soft and flexible due to the use of plasticisers. This softness helps the vinyl mould to the surface, filling small pits and gaps. Greater surface contact increases the overall strength of the cling.

What Are van der Waals Forces?Van der Waals forces are weak attractions between neutral molecules. They happen when the molecules are very close together. These forces come from temporary changes in how electrons are shared, which create slight positive and negative areas that pull the molecules toward each other. There are three types:

These forces help static cling stickers stick to smooth surfaces. They also matter in coatings, adhesives, drug design, and nanotechnology. Scientists use them to study how molecules behave and separate. |

Static cling stickers consist of three layers:

Let’s look at these layers.

The cling film is made from soft, flexible plastic that enables it to form close contact with smooth surfaces. Most cling films are based on calendered PVC, selected for its dimensional stability and natural cling behaviour.

Manufacturers add plasticisers such as phthalates or citrates to achieve the required softness. This flexibility helps the film conform to surface variations, improving adhesion strength through increased molecular contact.

Cling PVC films are typically 150 to 250 microns thick.

New films may appear slightly hazy or oily due to plasticiser migration, but this effect fades after application. The film resists tearing and stretches enough to allow easy handling during installation without permanent deformation.

Polyethene (PE) is sometimes used as an alternative to PVC. PE cling films are fully recyclable and remain clear over time because they do not require plasticisers. However, they may cling less firmly and are often used in environments prioritising sustainability over grip strength.

Only one side of the cling film is printable. In some stickers, this surface is treated through corona discharge or coated with a primer to accept different ink types.

These stickers can be printed via screen printing, UV offset, digital inkjet (eco-solvent, solvent, latex, UV), and thermal transfer.

Clear cling films are often reverse-printed for application inside windows, allowing the graphic to face outward while remaining protected.

The release liner protects the cling surface until use. Most liners are made from between 140 and 180 grams of silicone-coated paper per square metre, though some products use clear polypropylene liners to improve recyclability and transparency during alignment.

The liner provides a stable base for cutting and printing, prevents dust contamination, and maintains flatness in storage. It is discarded before installation.

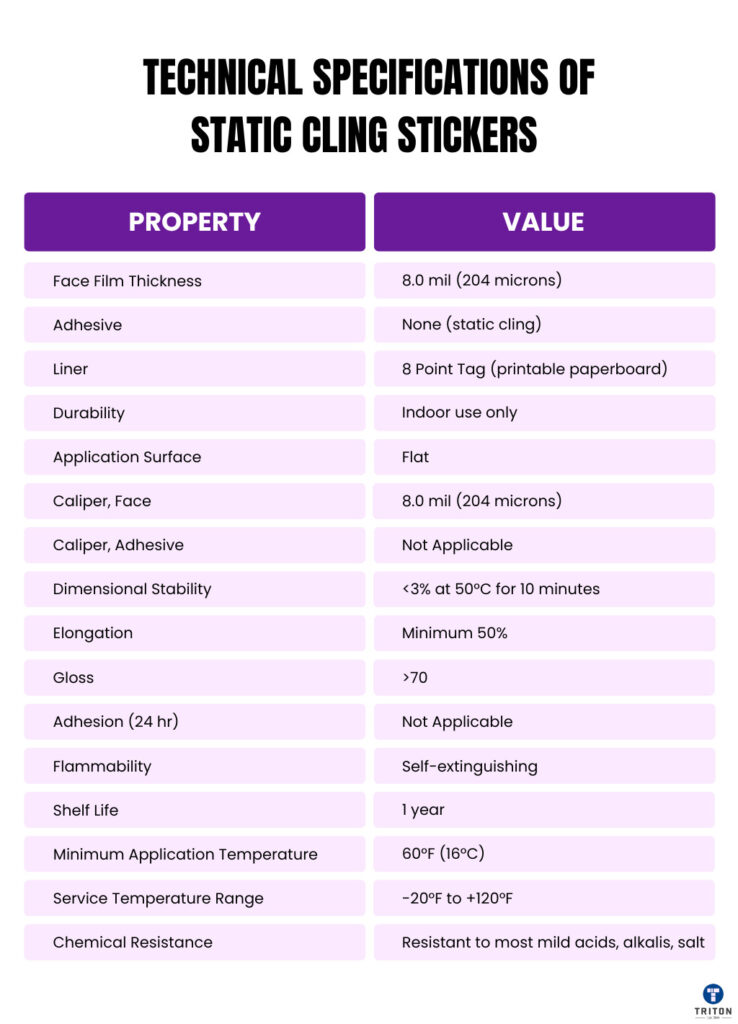

Understanding these specifications will help you select a sticker that fits your application and applies correctly across different surfaces and environments you care about.

Here are the specifications of static cling stickers.

Static cling vinyl films are typically 150-200 microns thick.

For example, Metamark’s MD-SC film measures 170 microns, while Avery Dennison’s SF 100 series is 204 microns thick. Dura-ID offers a 160-micron film. The release liners vary in thickness; Metamark uses a 180gsm kraft liner, and Avery Dennison employs an 8-point tag liner.

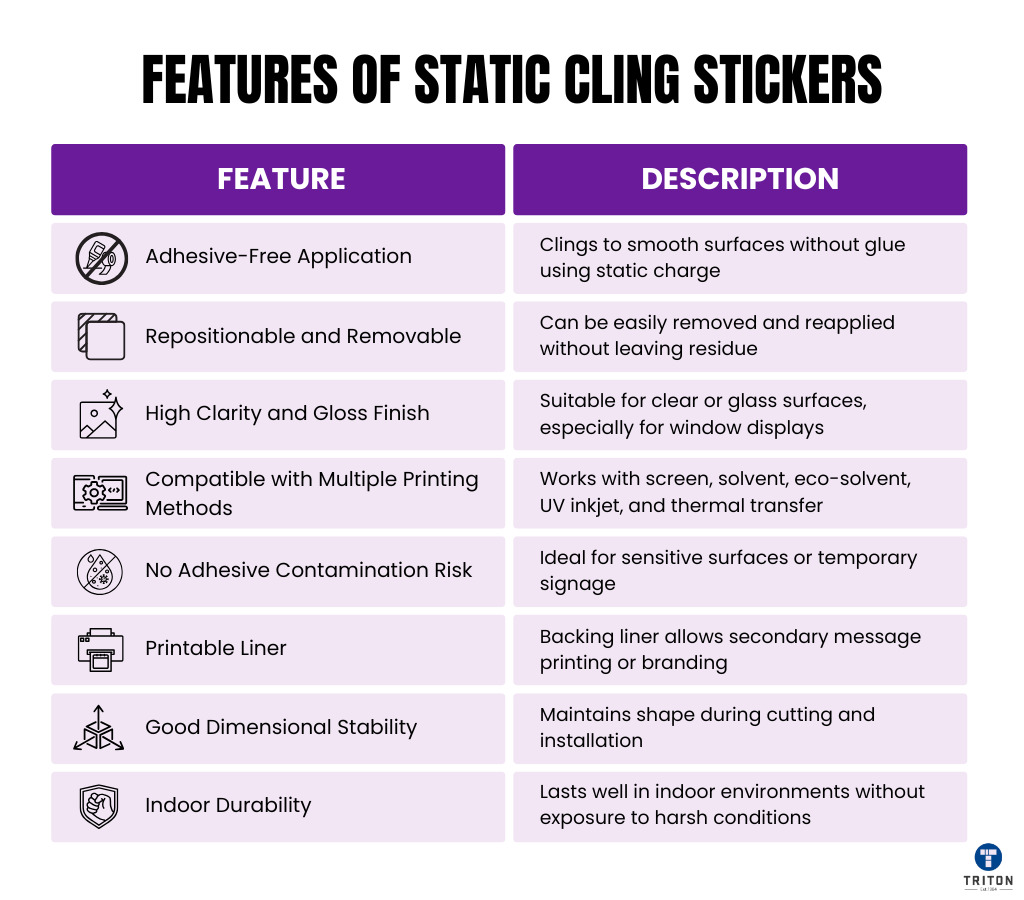

Static-cling stickers adhere via molecular attraction and the surface tension of the vinyl film. They suit temporary applications on clean, smooth surfaces such as glass or metal and allow easy removal and repositioning without leaving residue.

Static cling vinyl performs reliably within a moderate temperature range. Most products are suitable for use between −20 °C and +50 °C, covering typical indoor and controlled outdoor environments. For example, Metamark specifies a service temperature range of -20 °C to +50 °C. Avery Dennison’s SF 100 series operates between -20 °C and +49 °C.

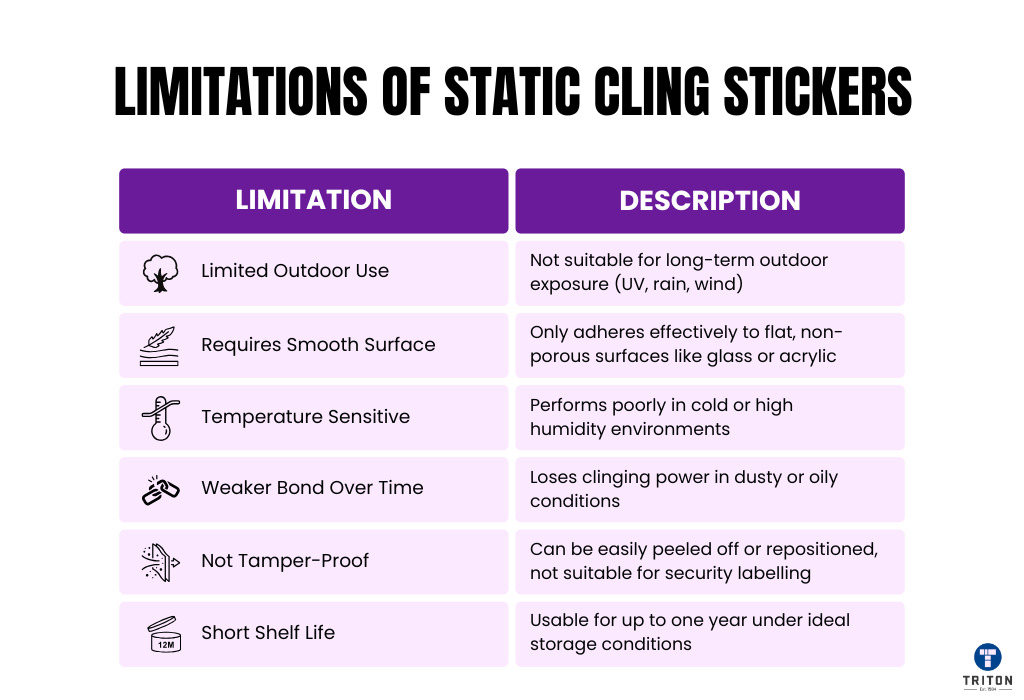

Static cling stickers are designed primarily for indoor use. Metamark rates their MD-SC film for up to three years indoors and up to two years in mild outdoor conditions.

Avery Dennison’s SF 100 series is intended for short-term indoor applications. Exposure to sunlight, rain, and wind may shorten the sticker’s lifespan.

Cling vinyl is resistant to water, mild detergents, and common cleaning agents. Metamark’s MD-SC film can be wiped clean using water and non-abrasive detergents, but is not recommended for immersion in esters, ketones, or gasoline. Avery Dennison’s SF 100 series is resistant to most mild acids, alkalis, and salt solutions.

Metamark’s MD-SC film exhibits excellent tensile strength (≥16 N/mm²) and is a soft PVC material, allowing flexibility during application without tearing. Surface hardness is not always specified, but cling films are generally smoother than laminated adhesive vinyls and more prone to scratching.

A clear protective laminate can be applied after printing for applications that require added durability.

Static cling stickers have a shelf life of approximately one year when stored under conditions defined by FINAT (20-25 °C, 40-50% RH). After this period, the film may lose its grip or feel oily.

The backing paper leaves marks if stored for a long time. To get the best results, store new stickers in clean, sealed bags away from heat and moisture.

Static cling stickers attach without glue or adhesive, allowing clean removal with no residue left behind. After use, surfaces like glass, stainless steel, or painted metal remain undamaged. For example, temporary vehicle graphics or equipment labels can be removed without scraping or solvents.

Clings lift off in one piece without tearing. Unlike paper labels, they do not leave fragments or sticky patches. If stored properly and kept clean, they can be reused multiple times, which makes them suitable for seasonal displays or repeat-use warehouse signage.

During installation, users can lift and adjust static-cling decals. This process does not impair the film or reduce its cling properties. Repositioning suits large-format graphics, where accurate placement and smooth application require adjustments.

When you apply them to a clean, smooth surface, they hold indoors for up to a few months. Some vinyl clings last up to about a year under stable conditions. They suit temporary promotions, signage and point-of-sale displays.

Static cling stickers perform best on smooth, non-porous surfaces. These include glass, acrylic, polycarbonate, glazed tiles, stainless steel, and glossy painted metal. Surfaces should be tested before use, especially painted finishes, as prolonged contact may leave a faint haze from plasticiser transfer.

Because there is no adhesive, static clings leave no residue on surfaces. They do not transfer ink or sticky material during application or removal. This makes them safe to place over printed signs or sensitive displays.

Cling films support full-colour, high-resolution printing. Most films have a glossy finish, which enhances image clarity and colour strength. Clear cling films are nearly invisible except where printed. Reverse printing allows the graphic to face outward through a window while protecting the print from weather or abrasion.

Static-cling vinyl flexes to follow curves on surfaces such as vehicle windows or container walls.

Installers position the film and press from the centre outward to expel trapped air.

The film maintains surface contact and prevents gaps and wrinkles.

Static cling stickers are waterproof and can be cleaned with water or mild detergents. Short-term exposure to rain does not affect their performance, as they contain no water-soluble adhesive. Most cling resists UV yellowing indoors and tolerate mild chemical cleaners, including ammonia-based glass sprays.

Static cling stickers meet safety standards for use in consumer and indoor environments. Many films use phthalate-free plasticisers and follow chemical regulations such as REACH. Without adhesives, they do not release solvents or harmful gases. Most cling vinyl materials also meet fire safety ratings such as UL 94 VTM-0, showing they are self-extinguishing and do not support flames.

Print shops use digital, screen, offset or flexographic presses to apply inks to static-cling vinyl films. Technicians pick ink based on graphic detail and end-use conditions. For gradients or photo images, they use UV-curable ink; for displays in direct sunlight, they use solvent ink; for settings with ventilation limits, they use eco-solvent ink.

After printing, technicians die-cut or kiss-cut each decal, inspect edges, and package for delivery.

Static cling films accept a range of printing techniques suited to different production needs.

Screen printing uses a mesh frame and stencil to force ink through open areas onto the vinyl surface via a squeegee. This method suits high-volume runs by delivering consistent ink opacity and bold colours.

Both solvent-based and UV-curable inks bond well to non-topcoated static-cling vinyl.

Screen-printed clings resist fading under indoor lighting and handle frequent handling.

Offset printing transfers ink from a metal plate to a rubber blanket onto the vinyl film. UV offset cures ink instantly under ultraviolet light, producing sharp, photorealistic images.

Conventional offset inks require a topcoat on the cling film to secure adhesion and prevent smudging.

This process excels at long runs of product labels and detailed window graphics.

After printing, technicians die-cut or kiss-cut each decal to shape, inspect edges, and package for delivery.

Digital inkjet printing is preferred for short runs, prototypes, or custom artwork. Inkjet printers using solvent, eco-solvent, latex, or UV inks produce full-colour images directly on the film. Proper curing is essential to avoid ink retention that may weaken cling performance.

Thermal transfer printing is used for small-format labels with variable data, such as barcodes or serial numbers. This method prints directly onto the film using thermal ribbons and supports on-demand jobs.

Other processes, such as letterpress, flexographic, and HP Indigo printing, are also used in speciality or niche applications requiring specific finishes or small-scale runs.

After printing, the inks are dried using UV lamps or heated ovens to ensure proper curing and image stability.

After the labels are printed, converters trim cling sheets to shape and size using die-cutting or rotary-cutting methods.

Die-cutting forces the vinyl and liner through steel-rule or rotary dies for consistent, repeatable shapes. Rotary cutters handle long runs at high speed, while flat-bed dies deliver precise cuts for intricate designs.

CAD plotter cutting uses computer-guided blades to trace complex outlines. It is suitable for low-volume orders or customised graphics.

Trimming with guillotines or shears is used for rectangular or circular decals, such as posters and large window displays.

Waste removal and stacking follow the cutting process. As the film does not contain adhesives, excess vinyl is lifted cleanly, and the remaining decals are stacked or rolled for handling.

Applying static cling stickers correctly requires little training and skill.

There are two ways: dry and wet, each suitable for different situations. Both approaches rely on careful surface preparation.

No matter the application method, the surface must be clean, dry, smooth, and at room temperature. Any dust, dirt, oil, or even slight grime can weaken adhesion and cause air bubbles. Clean the surface thoroughly using glass cleaner or an isopropyl alcohol solution and allow it to dry completely.

Avoid extreme temperatures.

Temperatures below about 10°C risk moisture condensation, reducing cling effectiveness. Temperatures above about 30°C can soften the vinyl backing and cause the sticker to stretch or slip. To ensure adhesion, apply between 15°C and 25°C. Keep stickers and the surface out of direct sunlight until you apply. That prevents heat build-up that can weaken the cling.

You can apply small decals (up to 300 mm) dry: peel off the liner, press the sticker onto a clean surface and smooth out bubbles with a squeegee or credit card.

For larger or detailed graphics, use the wet method: mist both the surface and the decal with a mild soapy-water mix, slide the film into position, then squeegee from the centre outward to push out liquid and air.

Both methods let you shift the decal into place as you go, then remove and reuse it cleanly without residue.

Before applying the cling, make sure the surface is:

This method works best for decals up to A4 size.

Steps:

This method is better for large decals or shapes with fine detail.

Steps:

Clings applied inside a window last longer because they are protected from sunlight, wind, and rain. Use reverse-printed clings if they need to be seen from outside. Outside mounting is easier and more visible, but the exposure may shorten the life of the decal.

Static cling decals work best on clean, smooth, and non-porous surfaces. Avoid applying them to textured, frosted, or matte finishes, as these reduce surface contact and can cause the decal to detach. Coated glass should be tested before use because treatments such as Rain-X or silicone-based coatings can prevent the cling from holding. Static clings do not perform well on fabric, rough paint, or porous materials, where the vinyl cannot form a consistent seal.

After installation, check that all edges remain sealed. If any lift, clean the surface again and reapply. To remove the cling, peel slowly from one corner. This prevents the film from stretching. To reuse a cling, rinse it with lukewarm water, dry it using a cloth that does not leave lint, and store it flat on the original liner or a smooth plastic film. Keep it in a cool place away from moisture and sunlight.

Static cling stickers work on clean, flat surfaces for short-term use. Their performance depends on surface type, temperature, and moisture.

Static cling stickers need little maintenance. However, routine care helps preserve grip and appearance over time, especially in commercial settings.

Proper cleaning restores contact between the cling and substrate and prevents grip or unwanted residue loss.

Wipe the substrate with a cloth and mild detergent or isopropyl alcohol to remove dust, oil and residue. Don’t use ammonia or bleach-based cleaners; these leave streaks or damage the vinyl film. Rinse with clear water and use a dry cloth or paper towel to eliminate moisture. Let the surface air-dry thoroughly before applying the cling.

Submerge the cling in warm water mixed with a drop of dish soap and lift off dirt by rubbing with a cloth. Rinse the film under running water to clear all soap, then lay it on a clean, dry surface to air-dry. Do not use solvents such as acetone or alcohol, which can break down the vinyl or fade inks.

Don’t use scraping tools that can nick or scratch the film; reuse fails if the surface layer tears. With both film and substrate clean and dry, static-cling stickers will adhere firmly, free of bubbles or gaps, and remain easy to remove and reuse.

Cling film can stretch or crease if handled roughly. Limit peeling or repositioning to keep their shape. Repeated removal can cause dust build-up or warping. Avoid pressing with fingernails or sharp tools, which can leave permanent marks or air pockets.

Humidity and temperature can affect cling performance. In cold areas, wipe off condensation to restore grip. In dry spaces, reduce dust by using anti-static spray near, but not on, the cling side.

Clean the cling and surface for long-term use every three to six months. This limits dust, prevents ghosting, and keeps the cling clear. Decals left in one spot for too long can become hazy or hard to remove. Rotate or replace them to maintain performance.

Store unused clings flat or rolled on a large core. Keep the cling against a liner, wax paper, or plastic film. Use a cool, dry place away from sunlight. Seal in a bag to block dust. Most clings last up to a year before signs of ageing appear, such as oily residue.

Handle the clings by the edges to avoid skin oils. Support large decals fully to prevent folding. If layers stick together, separate them gently with water. Avoid creasing, as it can affect flat application.

Damaged clings-creased, torn, or stretched-usually cannot be repaired. Avoid using glue or tape, as this leaves residue. A small piece of tape may hold a lifted edge temporarily, but replacement is best for professional use.

Check regularly that the cling stays in place, primarily where it provides safety or information. A loose decal can block vision or confuse you; clean and reapply it if it lifts.

In industrial use, static clings are easier to maintain than adhesive labels. No residue removal is needed. Facilities often wipe containers and return cling labels to their liners, keeping them ready for reuse.

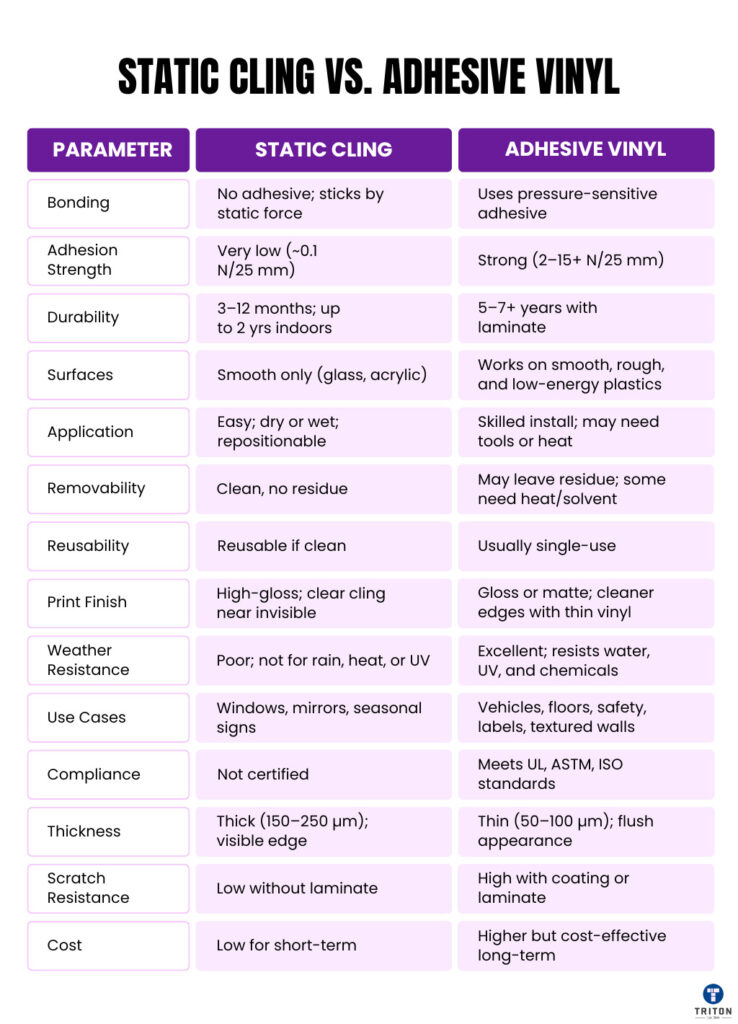

Parameter | Static Cling | Adhesive Vinyl |

|---|---|---|

Bonding Mechanism | Van der Waals forces and minor electrostatic attraction; no adhesive layer. | Uses pressure-sensitive adhesive (PSA) like acrylic or rubber-based; bonds by molecular diffusion and fills surface micro-crevices. |

Adhesion Strength | Extremely low. ~0.1 N/25 mm (10-20 g/inch) on glass. Often not listed in FINAT/ASTM standards due to low values. | Removable vinyl: ~2 N/25 mm (e.g. FINAT FTM-1). Permanent vinyl: >15 N/25 mm (1500+ g/in). 10× to 100× stronger than static cling. |

Durability & Longevity | Short-term: 3-12 months typical; up to 2 years indoors. Losses cling over time due to dust, moisture, or plasticiser loss. | Long-term: 5-7 years+ outdoors with laminate. Adhesive bond strengthens over the first 24-72 hrs (per ASTM D3330). Suitable for extended outdoor use. |

Surface Compatibility | Works only on very smooth, high surface energy substrates like glass, acrylic, polished metals. | Compatible with smooth and rough surfaces. Special adhesives enable use on low-energy plastics, textured walls, fabrics, and more. |

Application Method | Easy, repositionable. Supports both dry and wet application. Allows adjustment and smoothing without damaging material. | More demanding. Permanent adhesives may grab instantly. Air-egress and repositionable adhesives exist but require more skill to install without bubbles or misalignment. |

Removability | Instant and clean. No residue. Can be peeled by hand without tools. | Varies. Removable PSA peels cleanly, but after long exposure may leave residue. Permanent PSA often requires heat or solvents to remove. |

Reusability | Highly reusable if kept clean. Can be removed, cleaned, and reapplied multiple times. | Generally single-use. Adhesive becomes contaminated or degrades after removal. Some repositionable adhesives may allow 1-2 reuses. |

Print Quality and Appearance | High-gloss finish. Clear clings appear nearly invisible on glass. Thicker vinyl makes edges slightly more visible. May show edge silvering if not flat. | High-gloss finish. Clear clings appear nearly invisible on glass. Thicker vinyl makes edges slightly more visible. May show edge silvering if not flat. |

Environmental Resistance | Limited. Not suitable for rain, prolonged humidity, or high heat (>50 °C). Vulnerable to condensation, dust, and UV degradation. | Excellent. Weatherproof types resist moisture, heat, cold, chemicals. UV-blockers and laminates allow years of outdoor exposure. |

Specialty Uses | Short-term window signs, mirror labels, equipment protection masks, reusable seasonal signage. | Floor graphics, vehicle wraps, safety labels, reflective signs, regulatory plates, wall graphics-especially for curved or textured surfaces. |

Regulatory Compliance | Not compliant with UL, ASTM, or MIL durability standards. Not suitable for permanent safety or compliance labelling. | Commonly used in regulated industries. PSA vinyls meet UL 969, ASTM D3330, ISO 15184, and other certification standards for durability and safety. |

Thickness | Typically thicker (150-250 µm / 6-10 mil). Offers rigidity but more visible edges on glass. | Varies widely. Thin options (50-100 µm) available for subtle, flush-mounted applications. |

Scratch & Chemical Resistance | Limited unless laminated. Unprotected surface is more prone to scratching or chemical damage. | Often laminated or clear-coated for abrasion and chemical resistance. More durable under cleaning, handling, and harsh exposure. |

Cost | Low material cost. Often cheaper than PSA vinyl for short-term jobs. | Higher upfront cost, especially with laminates or specialty adhesives. Cost-effective over long service life. |

Static cling stickers provide a clean, reusable labelling option for smooth surfaces without adhesive. Their straightforward application, repositioning, and removal make them ideal for short-term use in retail, logistics, and industrial settings. While limited by surface type and lifespan, they offer practical value for temporary displays, signage, and equipment marking.

For high-quality printers, labels, and accessories to complement your labelling needs, explore the complete range at the Triton Store.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below