Every weighing task starts with the same question: how precise must it be?

From there, other factors quickly follow – durability, usability, cost and whether the scale suits the environment.

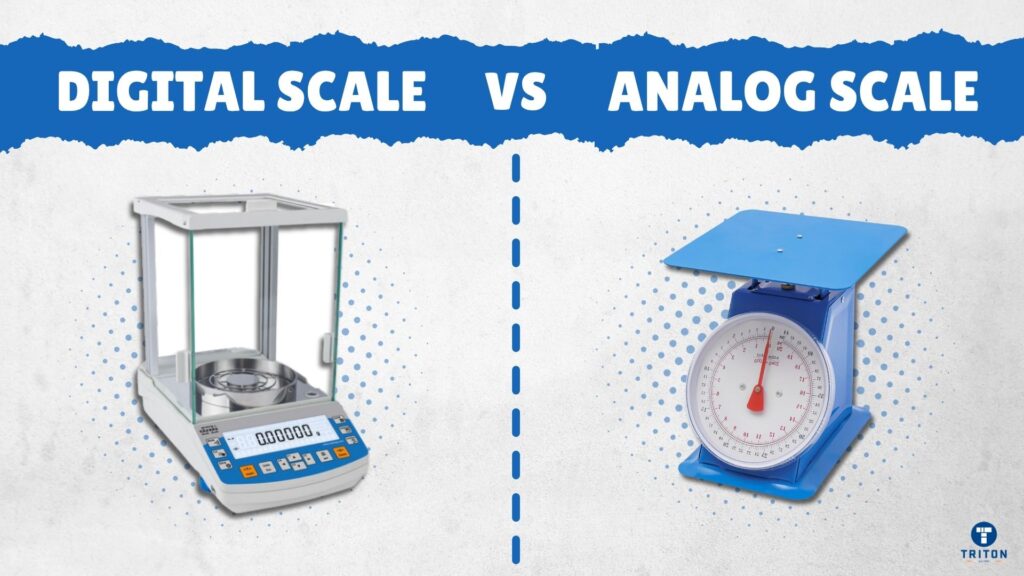

Digital models dominate labs and regulated industries, delivering accuracy within fractions of a per cent and offering features like auto-tare, calibration, and data transfer.

Analogue scales trade that precision for resilience. Their springs and levers can shrug off dust, moisture, and rough handling for decades, with no power source required.

The choice is rarely about technology. It’s about matching the tool to the job: fine measurement in controlled spaces, or dependable readings in tough conditions.

Understanding where each type excels helps buyers cut through marketing claims and focus on what matters – whether the scale needs to be highly accurate, or simply reliable day after day.

Digital scales are precise within ±0.02 – 0.1% of their capacity and have resolutions down to 0.5 g, with extras like tare, calibration, and data output.

Analogue scales are accurate to about ±0.1 – 0.5%, use springs and dials that resist dust, moisture, and power failures, often lasting decades: digital suits labs, packing, and compliance-heavy industries.

Analogue fits farms, warehouses, and scrap yards where “close enough” is enough. The choice is simple: digital for accuracy and features, analogue for rugged reliability.

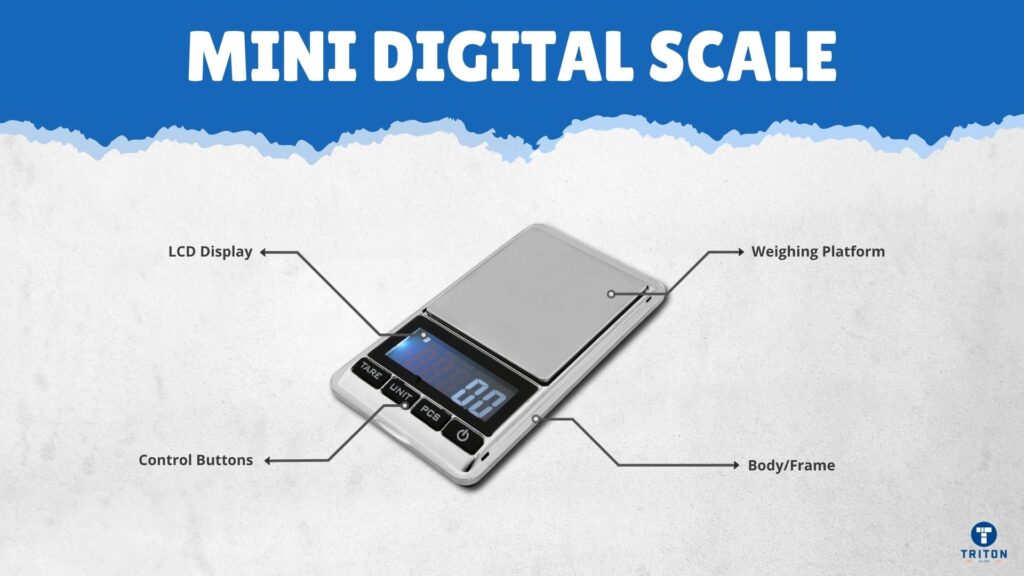

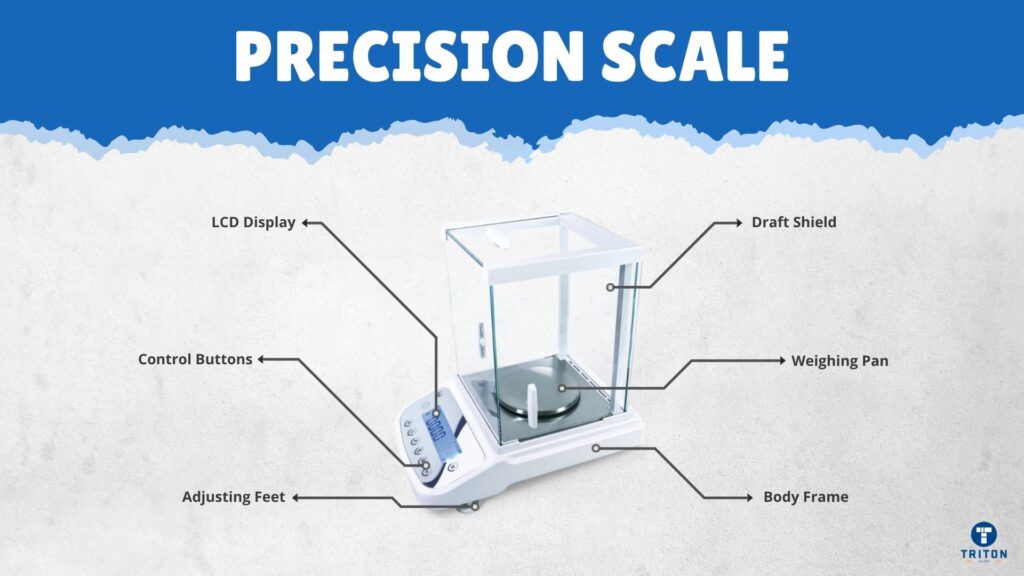

Before comparing these scales in detail, let’s take a quick detour to understand digital and analogue scales.

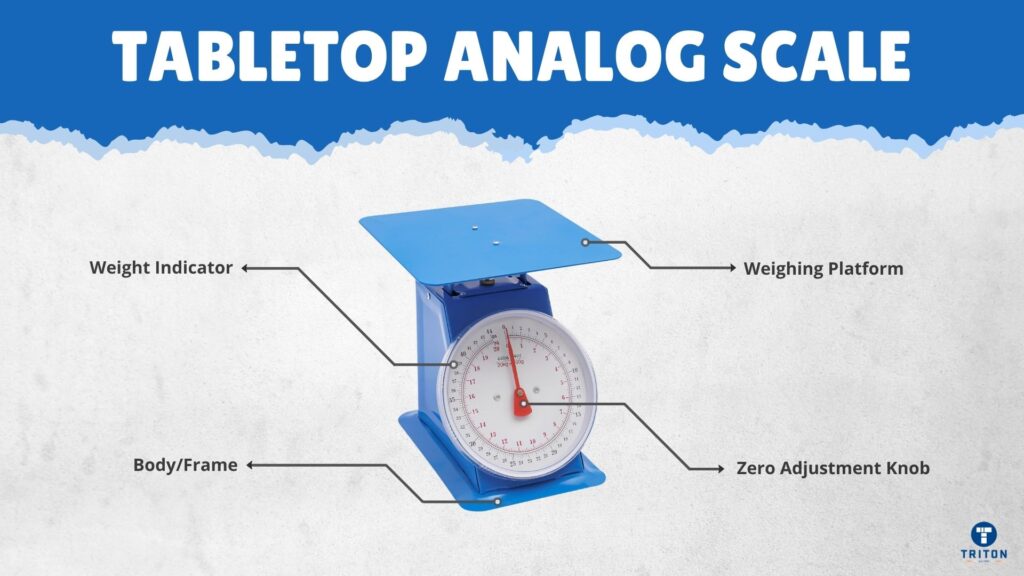

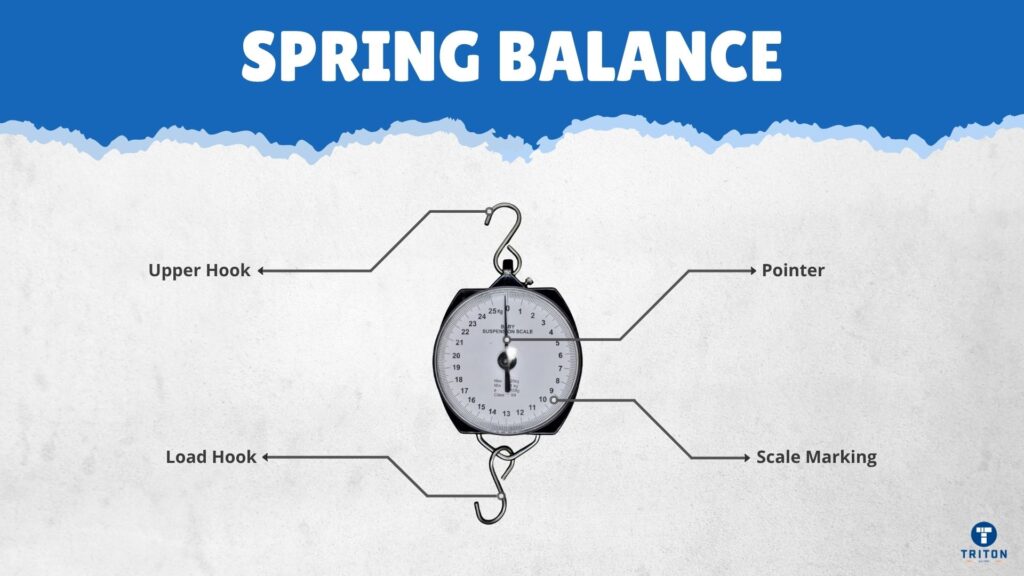

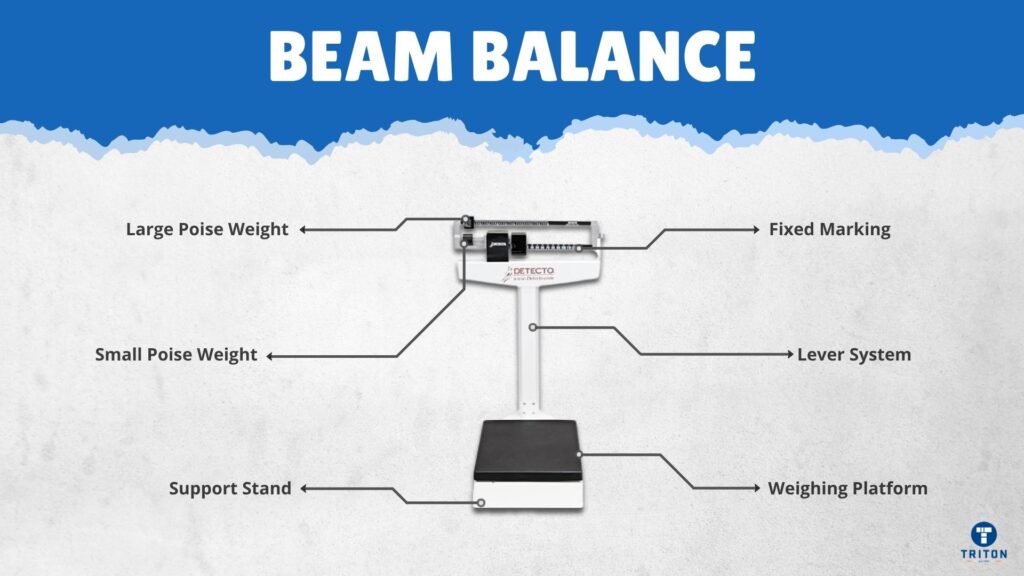

Analogue scales are mechanical weighing instruments that measure weight via physical movements such as spring compression, beam balance lever arms, or deflection of a pointer rather than digital electronics. They display weight via a dial, pointer, or sliding masses, requiring no batteries or electronic components.

Digital scales convert weight into an electronic signal via strain-gauge, capacitive, or piezoelectric load cells and then process it through amplifiers and A/D converters to display precise weight values.

Digital scales have high precision: lab digital scales have accuracy in the range of ±0.001 g to ±0.01 g on sensitive ranges, or ±0.1% of full scale for industrial units.

Resolution may be up to 1 in 100,000 counts in high-end precision devices, and 1 in 1,000 to 1 in 10,000 for general industrial types.

Digital scales deliver higher accuracy, repeatability, multi-functionality, and near-instant display, but they also require power, regular calibration, and greater investment than analogue scales.

When comparing accuracy and resolution across the full range, digital scales span from ±1 µg on microbalances to ±0.03% of capacity on 100-tonne weighbridges. Analogue scales range from ±0.05 g on laboratory beam balances to about ±0.5% of capacity on spring and dial models.

Digital systems reduce human error with direct numerical readouts, while analogue designs are affected by mechanical tolerances, wear, and parallax in dial reading, leading to greater variability over time.

Feature | Analog Scales | Digital Scales |

|---|---|---|

Resolution | Coarse increments (e.g., 0.5 kg or 0.2 lb) on dial; limited by scale markings. | Fine increments (e.g., 0.01 g or 0.1 kg) via electronic display. Limited by significant digits in the digital readout. |

Accuracy | Dependent on mechanical condition; springs can stretch; reading error from needle positioning. | High accuracy; sensors and digital readouts reduce misreading; calibrated for consistency. |

Repeatability | Poorer over time as springs and dials wear; manual reading variability. | Better repeatability; digital sensors and A/D conversion give consistent readings for much longer periods |

Environmental Influence | Temperature, humidity, and mechanical wear affect accuracy significantly. | More stable, though still sensitive to extreme conditions; calibration helps. |

User Reading Error | Higher: needle may wobble; difficult to discern exact weight on dial. | Lower: numerical display avoids visual ambiguity. |

Analogue scales withstand physical abuse, like drops, dust, and high vibration, better than many digital models because they don’t use delicate electronics.

Analogue scales also don’t fail from a dead battery or a surge.

However, they suffer from environmental wear: temperature swings cause springs and metal parts to shift or expand, leading to drift, while humidity can corrode components and loosen calibration. Mechanical wear (e.g., spring loosening or pivot corrosion) accumulates over time and degrades the precision of analogue scales.

Digital scales, if built with proper protection like sealed load cells, IP ratings, and corrosion-resistant housings, maintain tighter environmental tolerances. Still, the electronics are vulnerable: excess moisture, extreme heat, or cold can cause sensor drift, display failure, or shorter lifespan.

Exceptional models include shock-absorbing elements and reinforced casings, but these cost extra.

Environmental Factor | Analog Scales | Digital Scales |

|---|---|---|

Physical shock & vibration | High resistance; few fragile parts | Vulnerable – electronics and LCDs may crack unless ruggedised |

Temperature extremes | Spring tension changes, zero-point drift with heat/cold | Drift in load cell output or electronics; some models mitigate this with compensation |

Humidity & dust | Susceptible to corrosion and mechanical degradation | Risk of moisture ingress damaging circuitry; sealed models offer better protection |

Long-term wear | Springs and pivots loosen over time, affecting accuracy | Sensors stay stable longer but electronic components (e.g., displays) may fail |

Power issues | No dependence on power – always operational | Power failure (battery or mains) can render scale unusable when needed |

Cost for ruggedization | Base model already durable; less extra cost needed | Rugged variants (IP rated, heavy-duty) are more expensive |

Analogue scales indicate weight changes almost instantly because their mechanical linkages move continuously with force changes. Digital scales, however, must process signals, viz., sample, convert (Analogue/Digital), sometimes average, and then display a value, causing a short delay. In stable conditions, results appear fast, but digital units can lag by hundreds of milliseconds under rapid load changes.

Category | Analog Scales | Digital Scales |

|---|---|---|

Display Speed | Near-instant, continuous movement | Update delay due to sampling and processing |

Transient Handling | Displays fluctuations immediately | May smooth or delay transient changes |

Typical Delay | On the order of milliseconds or less | Often tens to hundreds of milliseconds in real-world use |

Digital scales cover the broadest span of measurement. Microbalances can detect as little as one µg (0.000001 g) at the low end, offering excellent resolution. At the high end, digital floor, truck, and rail scales measure 100 tonnes or more, while still giving usable precision.

Analogue scales operate across a narrower spectrum. The most sensitive types, like triple-beam balances, usually resolve to about 0.1 g and handle capacities of a few kilograms. On the heavy side, mechanical platform and beam scales can manage 20 – 30 tonnes, but with coarse graduations compared to digital units.

Scale Type | Minimum Capacity / Resolution | Maximum Capacity |

|---|---|---|

Digital | ~1 µg (0.000001 g) | 100+ tonnes |

Analog | ~0.1 g | ~30 tonnes |

Compliance in weighing scales means meeting legal and technical standards that validate measurements in trade and regulated industries.

Scales must carry NTEP certification under the National Conference on Weights and Measures in the United States. The European Union requires CE marking and type approval under the Measuring Instruments Directive (MID).

In Australia, trade scales fall under the National Measurement Act 1960 and the Trade Measurement Regulations 2009, both enforced by the National Measurement Institute (NMI).

In New Zealand, the Weights and Measures Act 1987 applies, with Trading Standards responsible for ensuring that only type-approved and verified instruments are used.

Traceability links every calibration step to a recognised national or international standard, such as the International System of Units (SI), with laboratories accredited under ISO/IEC 17025. Without compliance and traceability, scale readings lose legal standing, risking fines, rejected transactions, and damaged credibility.

Requirement | US (NTEP) | EU (MID/CE) | Australia (NMI) | New Zealand (Trading Standards) |

|---|---|---|---|---|

Type Approval | NTEP Certificate of Conformance required | CE marking and MID type approval mandatory | NMI type approval under National Measurement Act | Certificate of Approval required |

Verification / Stamping | Verified and sealed before trade use | Initial verification and CE marking | Verified by licensed technician; sealed and marked | Mark of verification (AP or crown stamp) required |

Calibration Traceability | Traceable to NIST standards | Traceable to EU national metrology institutes | Traceable to NMI via NATA accredited labs | Traceable to MSL via IANZ accredited labs |

Ongoing Compliance | Re-verification required after repair or interval checks | Periodic inspection depending on instrument class | Re-verification required after repair or at intervals

| Certificate of accuracy renewed as required |

Enforcement | NCWM / State Weights and Measures | National metrology authorities in EU states

| NMI inspectors enforce | Trading Standards officers enforce |

Digital scales cover everything from small bench units to heavy industrial platforms. They are accurate and feature packed.

But they also need care like regular calibration, steady power, and protection from moisture or surges. Rugged IP-rated housings and surge protection help, and some models even calibrate themselves. Day-to-day upkeep usually means checking load cells and arranging servicing if faults appear.

Analogue scales range from simple beam balances to massive mechanical platforms. With no electronics, upkeep is lighter, but moving parts like springs and pivots can still wear or corrode, calling for cleaning, recalibration, or replacement.

Scale buyers weigh lifetime costs: digital scales provide efficiency gains and data integration, while analogue models often deliver decades of service with straightforward upkeep.

Digital and analogue scales each have clear strengths. Digital delivers precision, advanced features, and compliance support. Analogue offers mechanical resilience and long service life with little upkeep. The right choice depends on workload, environment, and regulatory needs.

For organisations upgrading or replacing weighing equipment, explore the range of trade-approved solutions at Triton Store to match your operational demands.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below