Store Location

Choose Your Store

You are currently in the Australian store. If you are located in New Zealand please select the correct store below.

You are currently in the Australian store. If you are located in New Zealand please select the correct store below.

TSC PEX Series print engines offer reliable, high-speed performance for automated labelling applications. Designed for use in print and apply systems, they combine precise media handling with strong integration capabilities to support demanding production environments.

This article outlines the key technologies behind the series, including dual-motor control, thermal printing options, and GPIO (General Purpose Input/Output) connectivity. It compares current 4-inch and 6-inch models based on resolution, media support, and interface options.

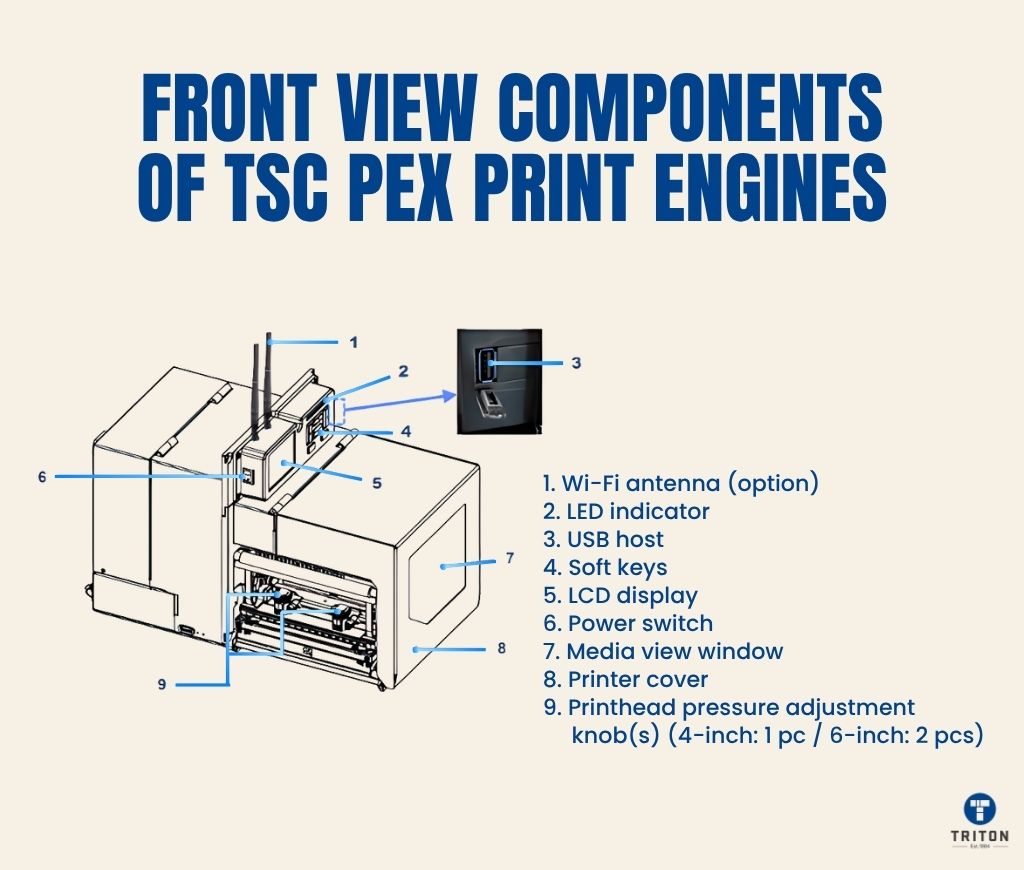

TSC PEX Series print engines integrate with labelling lines. They come in 4″ or 6″ widths and allow left- or right-hand configuration to suit line setup and customer preference. Each engine uses a die-cast frame, a colour LCD and dual-motor control to handle labels at high speed. On-device tools simplify setup, calibration and diagnostics. Models work with label formats and ribbon types.

These 4-inch, 203 dpi print engines are available in left-hand (L) and right-hand (R) orientations. They offer fast throughput with resolution suitable for shipping, pallet, and logistics labels.

Key Features:

These 4-inch, 300 dpi models are available in both orientations and are ideal for applications requiring more refined barcode and graphic output, such as product labels and retail packaging.

Key Features:

This left-hand 6-inch engine combines extended media width support with ultra-high 600 dpi resolution. It is well-suited for precision labelling in electronics, medical devices, and regulatory applications.

Key Features:

The PEX-2360L is a 6-inch, 300 dpi print engine designed for large-format labelling where speed and label width are prioritised. It supports detailed graphics, GHS-compliant chemical labels, and outer carton identification.

Key Features:

With 600 dpi resolution and wide-format support, the PEX-2640L is optimised for high-resolution GHS labelling, long-format regulatory content, and variable data with fine detail.

Key Features:

With a 203 dpi resolution and impressive print speeds, these 4-inch engines are designed to handle high-volume labelling effortlessly. Ideal for demanding workflows in manufacturing, warehousing, and distribution.

Key Features:

Compact 4-inch print engines with 300 dpi resolution, built for reliable, high-performance labelling in industrial environments.

Key Features:

Built for high-precision tasks, these 4-inch print engines produce clear, detailed labels at 600 dpi, ideal for industries where accuracy matters most.

Key Features:

The advantages of using TSC PEX Series print engines come directly from their precision-built design. Whether printing compact product labels or wide-format drum IDs, each model in the series is purpose-built for fast, consistent, and durable industrial labelling. Here’s a closer look at the engineering and integration features that power performance across all models.

TSC PEX Series print engines deliver high-speed label printing on demand, eliminating delays from pre-printed stock and enabling live variable data, barcodes, and product content per label cycle.

The 4-inch models, including the PEX-2240L and PEX-2240R, offer speeds of up to 457 mm/s (18 ips), making them suitable for rapid box labelling, carton IDs, and shipping workflows. The 6-inch PEX-2360L handles larger label formats at up to 305 mm/s (12 ips), making it ideal for GHS-compliant labelling and container labelling with large barcodes and detailed graphics.

All models process jobs in real-time and respond instantly to applicator signals, helping to maintain production flow without bottlenecks or queuing errors.

Across the PEX range, resolution options scale from 203 dpi for standard logistics applications to 600 dpi for fine-detail work. The 4-inch PEX-2340L and PEX-2340R support a 300 dpi resolution, striking a balance between performance and barcode legibility in high-density applications such as retail packaging and inventory management.

For demanding use cases that require micro text, serialisation, or compact 2D codes, the PEX-2260L and PEX-2640L deliver 600 dpi clarity on both narrow and wide labels. These models ensure consistent print contrast and clean edge definition, reducing scanning errors and maintaining compliance with regulated labelling requirements.

The 4-inch models in the series handle media up to 120 mm wide and support print widths of 104 mm, making them suitable for most product, shelf, and outer carton labelling. These units are often installed on automated conveyors or integrated into packaging lines where precision and speed are critical.

The 6-inch models – PEX-2360L, PEX-2260L, and PEX-2640L – support media widths up to 180 mm and print widths up to 168 mm. These models are used in applications such as pallet ID tags, chemical drum labelling, and large-format GHS compliance labels where space and content complexity demand wider output.

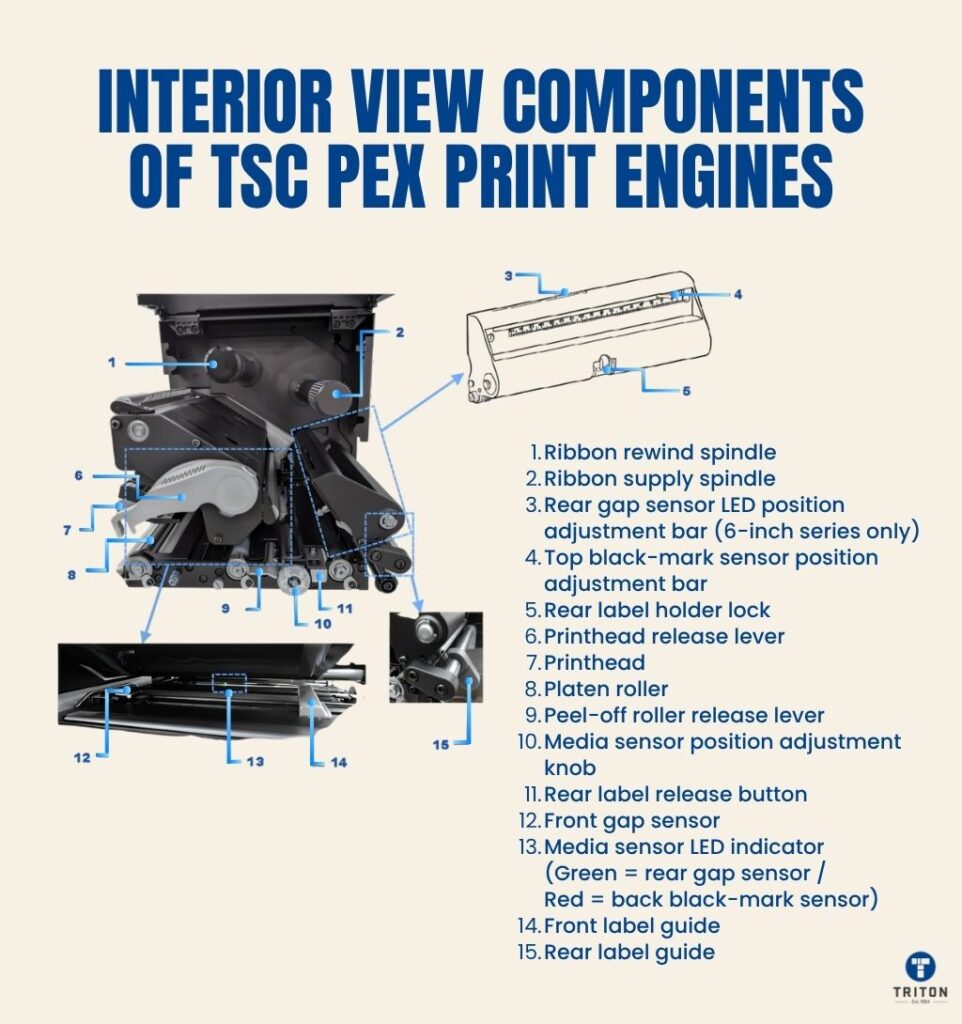

All PEX Series print engines feature dual-stepper motors that independently manage ribbon and media. This mechanism prevents ribbon wrinkling and maintains accurate tension across continuous or variable-length labels. The result is smooth feeding, clear registration, and consistent quality across extended print runs.

Sensor systems automatically detect gaps, black marks, or notches and support both continuous and die-cut media. Automatic calibration routines adjust feed position and top-of-form alignment, reducing manual input and setup time. The series supports up to 600 metres of ribbon, whether ink-side-in or ink-side-out, with widths ranging from 40 mm on 4-inch models to 180 mm on 6-inch units.

Each model includes a 15-pin GPIO port that interfaces directly with print-and-apply automation. This interface enables synchronised label application, pausing, and error response with external hardware such as tamp applicators, sensors, or conveyor-mounted PLCs.

Standard I/O functions include ribbon out, print complete, a job in progress, and applicator-ready signals. These functions are configurable on the device through the control panel or remote configuration tools. GPIO ensures responsive, hardware-level coordination for real-time industrial labelling.

The firmware across all models supports TSPL-EZ, ZPL, and DPL command languages. This ensures compatibility with existing thermal transfer print engines from other manufacturers, allowing label files and templates to be reused without redesign.

Native support for 1D and 2D barcodes, scalable fonts, variable data, and Unicode text ensures high-quality output across multilingual and data-rich label formats. Standard software packages, such as BarTender, NiceLabel, and Loftware, are supported using certified drivers, while integration with SAP and WMS platforms is seamless.

All models include USB 2.0, USB Host, Serial (RS-232), and Ethernet ports for direct integration. Optional wireless modules provide dual Wi-Fi and Bluetooth support, allowing use in mobile cart stations or network-segmented areas.

Each unit features a web-based management interface that is accessible through any standard web browser. IT teams can access job queues, firmware versions, sensor status, and usage logs. The PEX Series is compatible with SNMP for fleet-wide monitoring and integrates with remote management platforms such as TSC Console and SOTI Connect, helping reduce downtime and simplify device maintenance across multiple locations.

All PEX print engines feature rigid die-cast aluminium housings built to endure harsh operating conditions. These housings protect internal mechanisms from dust, vibration, and temperature changes, ensuring long-term reliability in manufacturing and logistics environments.

The 6-inch models utilise reinforced label paths and wider drive rollers to prevent oversized media from slipping or skewing. Maintenance is simplified by front-panel access to the printhead and platen roller, allowing routine service to be completed without the need for tools or production delays.

Each engine includes a 3.5-inch colour LCD with a six-button keypad for local control. Operators can perform sensor calibration, adjust print parameters, and execute diagnostics directly from the printer without requiring a host connection.

The system provides real-time alerts for ribbon end, media low, head open, and sensor fault. Print history and system logs can be exported for review, and test print functions are available for validating resolution, alignment, and barcode performance.

Setup across multiple units is simplified with USB configuration cloning, allowing a single profile to be replicated across an entire printer fleet.

The TSC PEX Series print engines are built for tough, high-speed label printing on automated production lines. They support different print widths and resolutions, making them easy to drop into existing setups. These machines don’t quit. They run non-stop in high-demand jobs like logistics, packaging, compliance labelling, and product tracking. Anywhere you need accuracy and speed, every single time.

Discover the TSC PEX Series at Triton Store. From 4-inch to 6-inch models, we provide trusted support, reliable stock, and fast shipping. Visit the Triton store to find the right print engine for your labelling system.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below