MaxiCode barcodes are free for public use and do not require a license or permission. You can generate them using online tools like MaxiCode Code Generator or software like Seagull Scientific’s BarTender Software.

To obtain a MaxiCode barcode, you can follow these steps.

- Choose a MaxiCode Generator: There are various software applications, online tools, and barcode generator libraries available that can generate MaxiCode barcodes. Look for a reliable and trusted generator that supports MaxiCode symbology.

- Enter the Data: Determine the information you want to encode in the MaxiCode barcode. This can include data such as tracking numbers, addresses, shipment details, or any other relevant information.

- Generate the MaxiCode Barcode: Click on the “Generate” or “Create Barcode” button to generate the MaxiCode barcode based on the provided data and settings.

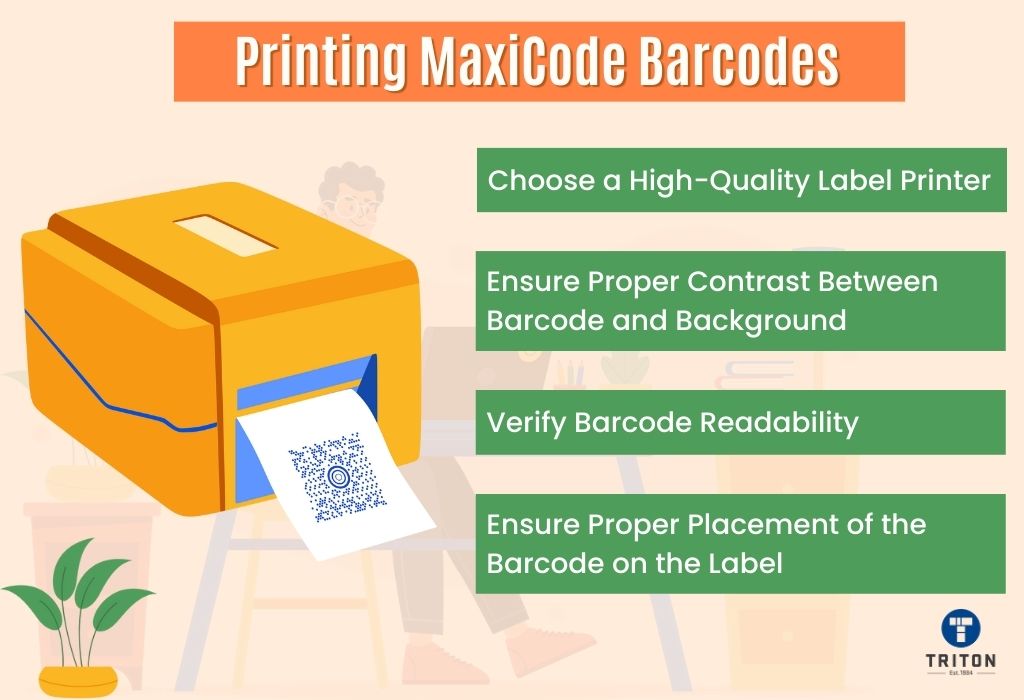

- Save or Print the Barcode: Once the MaxiCode barcode is generated, you can save it to your computer or directly print it.

- Test the Barcode: Before implementing the MaxiCode barcode in your business operations, it is advisable to test its readability using barcode scanning devices or software. Ensure that the barcode can be scanned accurately and the encoded data is correctly retrieved.

While free online barcode generators may offer a quick and convenient solution for generating MaxiCode barcodes, it’s crucial to consider their limitations. Here are some common limitations associated with free barcode generators.

- Limited customisation: Free barcode generators often provide limited options for customising the appearance of the barcode.

- Absence of technical support: Free barcode generators typically lack dedicated technical support. If you encounter any issues or need assistance with barcode generation, you may not have access to timely support or guidance.

- Security and privacy concerns: When using free online barcode generators, you need to upload your sensitive information to their servers. This can cause security and privacy concerns.

To overcome these limitations and ensure high-quality barcode generation, you should invest in paid barcode generators. They offer advanced features, customisation options, comprehensive technical support, and enhanced data handling capabilities.

One paid software we highly recommend to our customers is Seagull Scientific’s BarTender Software, the world’s premier label design and printing software.

Seagull Scientific’s BarTender Software is the ultimate solution for all your label design, management, and printing needs. With its comprehensive features and user-friendly interface, BarTender empowers users to create visually stunning labels that effectively communicate your brand image.

BarTender software offers a wide range of design tools, allowing you to incorporate graphics, logos, and text elements with ease. What’s more, the software supports RFID tags, enabling you to leverage the power of advanced label management. Experience the revolution in label design with Seagull Scientific’s BarTender Software.

At Triton, we understand that every business has unique label printing requirements. That’s why we offer all four editions of BarTender Software, including Starter Edition, Professional Edition, Automation Edition and Enterprise Edition. We also offer the latest addition to the BarTender family, BarTender Cloud enabling you to access and manage your label designs from anywhere, anytime. With Triton, you can be confident that you’ll receive top-quality software at the best prices.

To learn more about Seagull Scientific BarTender Software, contact us via the live chat widget below or fill out a form here.