Ultraviolet (UV) printing is a digital process that jets specially formulated UV-curable inks and solidifies them almost instantaneously using ultraviolet light.

Because the inks polymerise on the surface instead of drying by evaporation, UV printing delivers ready-to-use output on rigid boards, films, glass, metal, wood and other materials that traditionally required separate finishing steps.

As interest in on-demand manufacturing, mass customisation and sustainable production grows, UV technology has become central to signage, packaging, product decoration and industrial manufacturing.

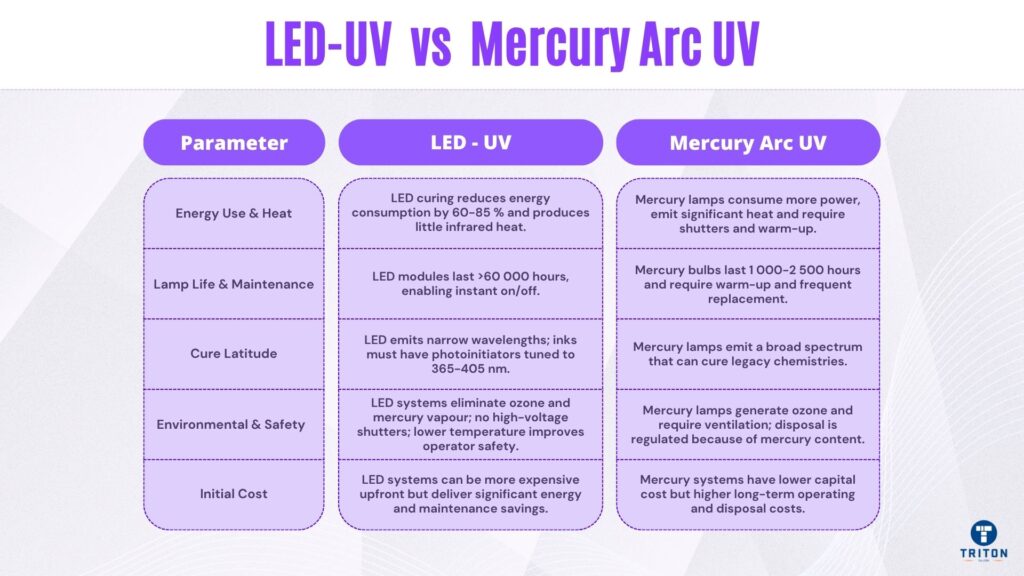

UV printing uses UV-curable inks made of resins, pigments and light-reactive compounds called photoinitiators. When UV light hits the ink, the photoinitiators trigger a chemical reaction to harden the resin into a solid layer. Earlier UV systems used mercury lamps that produced a broad spectrum, while most modern printers now use LED lamps. LEDs emit light in narrow bands, typically centred around 365, 385, 395 or 405 nm. These frequencies are tuned to match the photoinitiators in the ink. This precise matching ensures fast curing and limits heat on the substrate.

The process has three steps:

Modern UV printers use “pin and cure,” where a low-power lamp partially cures (pins) the ink after each pass and a high-power lamp completes the cure after all layers are deposited. Pinning controls dot gain and adhesion on uneven surfaces.

UV printing offers three things that every production manager values: speed, flexibility, and control.

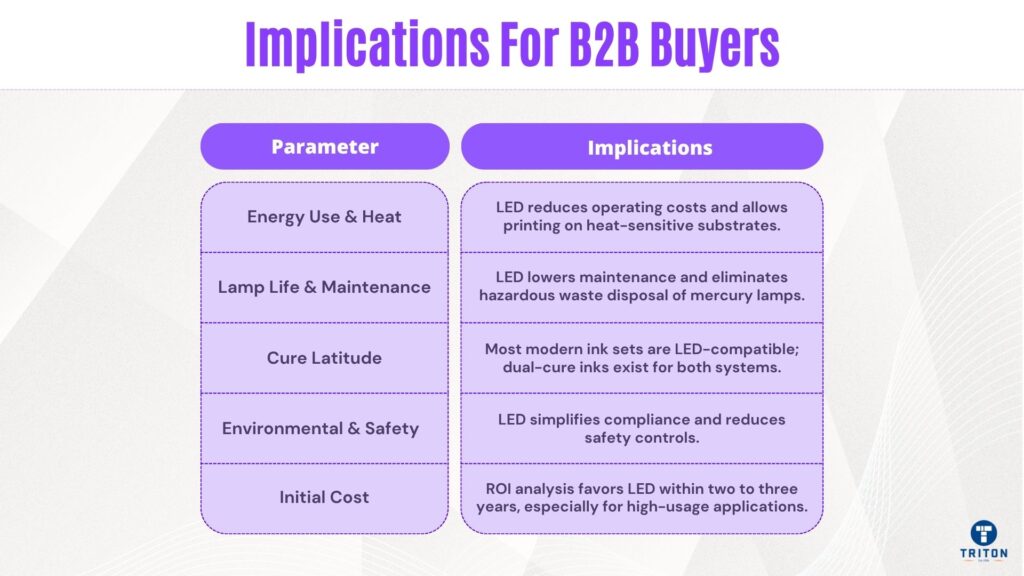

UV prints leave the press completely dry. There is no waiting, stacking or drying area. You move a sheet or part straight from the printer to finishing or packing. That saves time and floor space. Operators can switch jobs on demand and handle one-offs or micro-batches without downtime. LED curing systems draw about 60-80% less energy than mercury lamps and waste no time on warm-up. You get shorter lead times and better uptime.

UV inkjet technology prints directly on porous and non-porous materials. You handle glass, metals, ceramics, wood, plastic films and corrugated boards with one machine. Add primers or surface treatments like flame, corona or plasma, and adhesion becomes consistent, opening new print media, such as decorating consumer goods, industrial parts, and packaging without labels. Many manufacturers now print directly on bottles, appliances, and enclosures instead of applying decals or sleeves.

UV inks contain almost no solvents. They emit negligible volatile organic compounds, so no abatement systems are needed. The chemistry is solid resin and pigment, which reduces waste and eliminates solvent evaporation. LED curing uses focused light that produces little infrared heat, lowering ambient temperature and HVAC load. A single mid-size UV-LED printer saves 60-80% in curing energy and extends lamp life from 2,000 hours to over 60,000. That means fewer parts replaced, less downtime and fewer hazardous disposals.

LED curing removes mercury and ozone from the process, the hazards of high-temperature lamps and toxic bulb waste. Enclosed light sources and UV-blocking covers prevent radiation exposure. In regulated industries such as food packaging, buyers use low-migration UV inks and follow Good Manufacturing Practice under Regulation (EC) 2023/2006 to meet safety standards.

Flatbed UV printers are designed for rigid materials like glass, acrylic, metal, wood, and composite boards. A vacuum table holds the substrate in position while the print head travels above. Multiple vacuum zones stabilise uneven or smaller parts, and variable head clearance accommodates different thicknesses. LED lamps tuned to specific wavelengths (365-405 nm) ensure that every layer polymerises properly.

Pinning control allows sequential curing for accurate layering and surface textures. Typical flatbed systems achieve print speeds above 100 m² per hour. Regular calibration maintains consistent irradiance and uniform image quality.

Roll-to-roll systems print on flexible media such as vinyl, polypropylene, polyester or thin paper. They suit banners, wraps, and labels where continuous feed improves throughput. Tension control keeps alignment tight; anti-static bars prevent dust attraction and colour defects.

Tension control and anti-static features prevent stretching or wrinkling. Tension control keeps alignment right while anti-static bars guard against dust collection and colour defects. Inline sensors track edge alignment and detect roll defects.

Ink flexibility matters. Some UV inks, like those based on epoxy acrylate chemistries, are brittle when applied to flexible substrates. Researchers report that conventional epoxy acrylate oligomers tend to form highly crosslinked, rigid polymer networks that lack flexibility.

Hybrid printers merge flatbed and roll capability in one frame. They handle rigid panels and rolls without changeover. They use rotary jigs or multi-axis gantries to position parts under the print head. Integrated plasma or corona units raise surface energy before printing, for consistent adhesion on plastics or coated metals. Adjustable lamp angles and pinning lamps give an even cure on curved or recessed areas.

Since UV printing relies on light energy and ink-surface chemistry, stable process control is essential to keep the cure consistent and prevent failures.

Radiometry tracks lamp performance. Measuring irradiance and total energy verifies that lamps deliver the correct dose for polymerisation.

Surface preparation decides whether the ink bonds or peels. Oils, dust or residues interfere with curing, so cleaning and degreasing are standard before printing. Primers or adhesion promoters are applied to glass, metals and plastics with low surface energy. Flame, corona, and plasma treatment raise surface energy and improve ink wetting.

Adhesion is tested through cross-hatch cuts, tape pulls and scratch tests. These tests reveal under-cured layers or poor surface preparation. Temperature, humidity and lamp & ink age influence adhesion. Controlled print environments produce consistent results.

The UV printing market is expanding as industries move towards faster, cleaner and more flexible production methods. Global demand for UV inkjet printing reached around US$60 billion in 2025, growing at 10 per cent annually.

Forecasts place the market at US$86 billion by 2029. The growth comes from e-commerce packaging, industrial decoration, and manufacturers bringing printing in-house for short-run jobs.

Asia-Pacific is the largest producer of UV printers, driven by growth in packaging, signage and component marking. Europe and North America have shown steady adoption in industrial and graphic segments, supported by the shift to low-VOC technologies.

Flatbed printers are nearly half global installations, while compact roll-to-roll and hybrid systems expand rapidly on the back of flexible media print demand.

LED-UV devices now account for roughly two-thirds of new units sold. Their long service life and energy savings give the best return on investment for continuous production lines.

End-use sectors such as signage, OEM parts and packaging account for most demand.

Direct-to-object printing is the fastest-rising category, with applications in consumer goods, bottles and electronics housings.

The trend is clear.

Manufacturers are replacing solvent and heat-drying systems with LED-UV for its instant handling, reduced emissions and minimal maintenance. The technology’s momentum reflects how UV printing has moved from a niche option to a core industrial process for high-mix, low-volume production.

UV printing has a few constraints that affect flexible packaging, low-energy plastics and food-safe applications.

Epoxy acrylate inks are rigid and form dense crosslinked networks. These films crack when folded or stretched, limiting their use on flexible substrates such as shrink sleeves. Elastomeric or modified acrylate systems with elongation above 150 per cent keep prints stable on soft or bendable materials.

Low-surface-energy plastics like polyethylene and polypropylene resist bonding. They need flame, corona or plasma pretreatment to raise surface energy and primers to secure the ink film.

Food packaging uses low-migration UV inks engineered to block the transfer of uncured components. Cured films must form a stable barrier that prevents contact contamination during storage or handling.

High capital costs and the need for trained staff remain practical challenges. LED-UV systems are more costly than solvent-based units, and consistent output relies on technicians who understand irradiance, dose and cure control.

A structured checklist simplifies the evaluation of UV printing equipment and workflow integration.

Identify every substrate and finish required – rigid boards, flexible films, glass, or metal. Suppliers should provide adhesion and abrasion test data. Internal tests confirm durability under real production conditions such as folding, handling or temperature change.

The wavelength of the UV-LED lamp must match the ink’s photoinitiators. Typical peaks fall between 365 and 405 nm. Verify that the irradiance and total energy dose match supplier specifications for white and dark layers. Mismatched curing reduces adhesion and gloss consistency.

LED curing reduces power use by up to 80 per cent compared with mercury lamps. Lower heat output decreases HVAC demand, improving overall plant efficiency. Measuring actual power draw and temperature rise during trials provides accurate return-on-investment data.

Packaging printers must verify conformity with industry standards such as the Swiss Ordinance and Good Manufacturing Practice (EC 2023/2006). Supplier documentation should include safety data sheets, migration test reports and declarations of conformity.

Shielded housings, interlocked access panels and UV-blocking windows protect operators. LED systems remove the need for mercury lamp handling, ozone ventilation and high-temperature parts, reducing maintenance frequency and operator risk.

A robust ROI analysis should include:

UV printing has become a core digital process for industrial and commercial production.

It combines speed, precision and environmental performance while cutting waste and downtime. With its ability to print directly onto almost any surface, UV technology fits operations that value fast turnaround and consistent quality.

For Australian businesses investing in reliable printing solutions, Triton provides expert advice, professional support and a full range of printing equipment. Visit Triton Store to explore thermal printers, label printers and accessories that complement UV printing workflows and streamline production.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below