Over 400 million printers are active worldwide, spanning families as different as inkjets, lasers, thermal, impact, UV, and 3D. Some spray ink, others fuse toner, some strike paper, while advanced systems cure droplets with light or build objects layer by layer. From pocket devices to production presses, the diversity is vast. The list below presents every primary type organised by core technology.

Inkjet printers spray high-precision streams of tiny ink droplets directly onto paper. The print head moves back and forth, firing drops through nozzles that are often thinner than a human hair.

The printer forms sharp letters, smooth gradients, and full-colour images by controlling these droplets’ size, placement, and mix. Because the ink is delivered without physical contact, the system is quieter than impact printers and can achieve high resolution while staying mechanically simple.

Standard inkjet printers are the most common in homes and small offices. Their resolutions range from 300 to 1200 dpi, with higher end models reaching 2400 dpi or more. Print speeds average 5 to 15 pages per minute for black text and slightly slower for colour pages. Many models can print borderless photos, double-sided sheets, and support paper sizes from A4 to legal. They print plain paper, glossy photo stock, labels, and speciality media. Standard inkjet printers are a balance of cost, quality, and footprint.

High-definition inkjets have resolutions of 4800 dpi or higher. Printed text looks typeset, and images are lifelike in detail. Print averages 3 to 8 pages per minute, as more passes are required for sharpness. These printers support larger droplet variations (1.5 pL to 3 pL for fine details to 10 pL or more for filling solid colour areas) and print smoother tonal shifts in complex graphics. They are used for technical drawings, fine-art prints, and photographic enlargements.

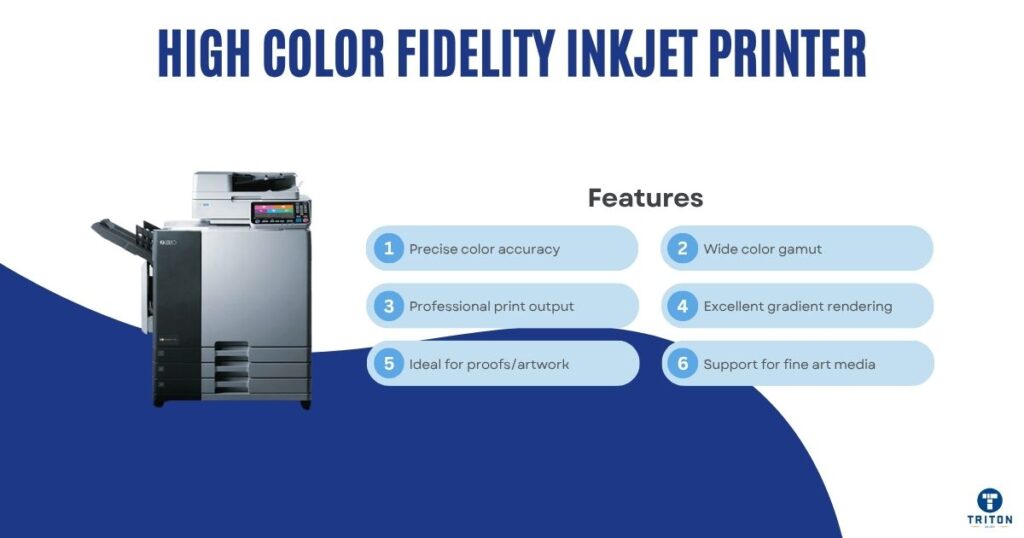

High fidelity inkjets reproduce colours with Delta E accuracy values below 2, which is near the limit of human perception. They use extended ink sets beyond CMYK, adding light cyan, light-magenta, orange, green, or violet to widen the gamut. Typical droplet volumes are 2 to 5 pL, and advanced screening algorithms like Stochastic Screening and Error Diffusion minimise banding. Output is profiled with ICC standards for consistent results across devices. These printers, such as the Epson SureColor P900 and Canon image PROGRAF PRO 1000, are used for tonal accuracy and subtle gradations like photography.

Continuous inkjet prints at high speed by producing an uninterrupted liquid stream and electrostatically deflecting it to form characters and markings. These printers can print 600 – 1000 meters per minute by generating millions of drops per second. Inks include solvent, water-based, and UV-curable chemistries formulated for fast drying and strong adhesion to plastics, glass, and metal. Print resolution varies between 60 and 300 dpi for alphanumeric text and barcodes. Special heads give finer detail. Maintenance requires scheduled cleaning and ink conditioning. Industrial systems integrate PLC controls, remote diagnostics, and inline verification functions.

Super tank printers store ink in large refillable reservoirs instead of disposable cartridges. A single refill set prints 5,000-7,000 black or 6,000+ colour pages. Cost per page is a fraction of cartridge systems. Transparent tanks let you track levels easily, and refill bottles reduce plastic waste. Print quality matches standard inkjets at 1200 to 2400 dpi, with average speeds of 10 to 20 ppm for text. They are popular for high-volume home and office use.

Laser printers use a laser beam to discharge selected areas on a charged “photosensitive drum.” The discharge creates an electrostatic pattern of the page image. A rotating polygon mirror directs the beam line by line, writing at resolutions of 600 to 1200 dpi in standard units and 2400 dpi in commercial systems. Dry toner particles adhere to charged regions of the drum and are transferred to paper through a “transfer roller”.

200 °C heat and pressure in the fuser assembly permanently bond the toner to the sheet. Office laser printers can print between 20 and 50 ppm, and commercial units can print at 200 ppm or more. Toner yields range from 1,000 pages in compact units to over 50,000 in high-volume cartridges. Laser prints are smudge-resistant, durable, and consistent at high throughput.

Monochrome laser printers use a single toner cartridge and print in black-and-white. A laser writes the image onto a photosensitive drum; toner transfers to paper and fuses under heat. The first page is printed in 4 to 8 seconds, and sustained speeds are between 18 and 55 pages per minute. Print resolution falls between 600 and 1200 dpi for crisp text. Monthly duty cycles range from 5,000 to 150,000 pages. Standard cartridges yield 2,500 – 25,000 pages, while enterprise cartridges exceed 50,000. Duplexing and large input trays (150 – 5,000 sheets) are common. Maintenance focuses on the drum, fuser, and feed rollers.

Colour laser systems operate on “layered electrophotography.” A modulated laser writes raster lines onto an organic photoconductor drum. Next, “sequential developer stations” apply polymerised toner with particle sizes typically 5-10 µm. An “intermediate transfer belt” or “direct transfer roller” aligns cyan, magenta, yellow and black separations with sub-pixel registration using optical encoders and closed-loop servo corrections.

Charge rollers and transfer bias voltages control electrostatic potentials. Toner transfer efficiency exceeds 95% in well-maintained systems. The onboard RIP rasterises PDF/PostScript into CMYK separations and applies micro-screening or stochastic halftone patterns for continuous-tone reproduction. Spectrophotometric sensors perform colour calibration and density feedback.

Fuser assemblies use ceramic or halogen heaters to reach 180-220 °C and apply pressure to coalesce toner polymers into the substrate. Replaceable consumables include OPC drums, developer housings, fusers and waste-toner containers; diagnostics track end-of-life and maintenance intervals. Colour laser printers print between 20 and 40 pages a minute, and commercial units print 60+ ppm.

High-speed production laser printing systems are used for large commercial runs and in continuous-feed and sheet-fed presses. They use polymerised toner with median particle diameters below 4 µm to produce smooth solids and tight mid-tone transitions.

Web-transport uses vacuum belts that grip the moving substrate, servo-driven rollers that regulate web tension, and optical edge-guidance sensors that monitor paper edges. These subsystems work together to prevent skew, wrinkles, and drift across the width of the roll. By stabilising the sheet path continuously, they maintain registration accuracy within ±0.1 mm and keep colour separations locked in place, even when the press operates at the highest rated throughput.

Multi-station development applies separations sequentially onto an intermediate belt; inline spectrophotometers measure density and initiate closed-loop correction. RIP farms process IPDS/PS/PDF at 1200-2400 dpi using stochastic screening and variable-data workflows. Fusing employs oil-less belts or induction heaters to lock the toner without substrate gloss variance. Monthly impressions exceed 1,000,000. Consumables include bulk silos, developer drums and replaceable fusing sleeves.

LED printers use a stationary array of light-emitting diodes to expose the image onto a photosensitive drum. The LED array aligns across the drum width, eliminating complex beam optics and reducing mechanical tolerances.

Effective resolutions range from 600 to 2400 dpi, determined by how closely the LEDs are spaced and how the driver circuits modulate them. The toner system follows the same principle as laser printers, using polymerised particles between 5 and 10 µm.

The developer unit charges the toner particles to the transfer stages. Transfer stages use bias rollers or an intermediate belt to move the toner image from the drum to the paper.

Thermal energy in the fuser melts toner polymers at approximately 170-210 °C to embed particles into paper fibres. LED engines offer immediate start, lower vibration, and simplified calibration routines because exposure timing relies on electronic gating rather than scanning mirrors.

Because the light source distributes evenly across the drum, these systems maintain consistent edge-to-edge density and reduce banding risks associated with misaligned optics. Manufacturers integrate onboard RIP processing, density sensors and registration controls to meet print quality targets and automate colour management.

Service items include OPC drums, developer housings and fuser assemblies.

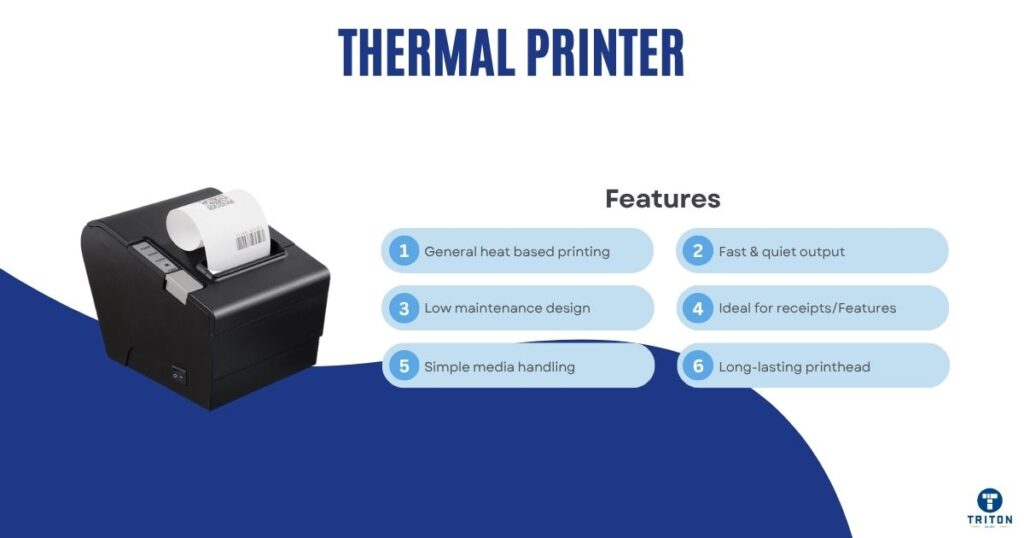

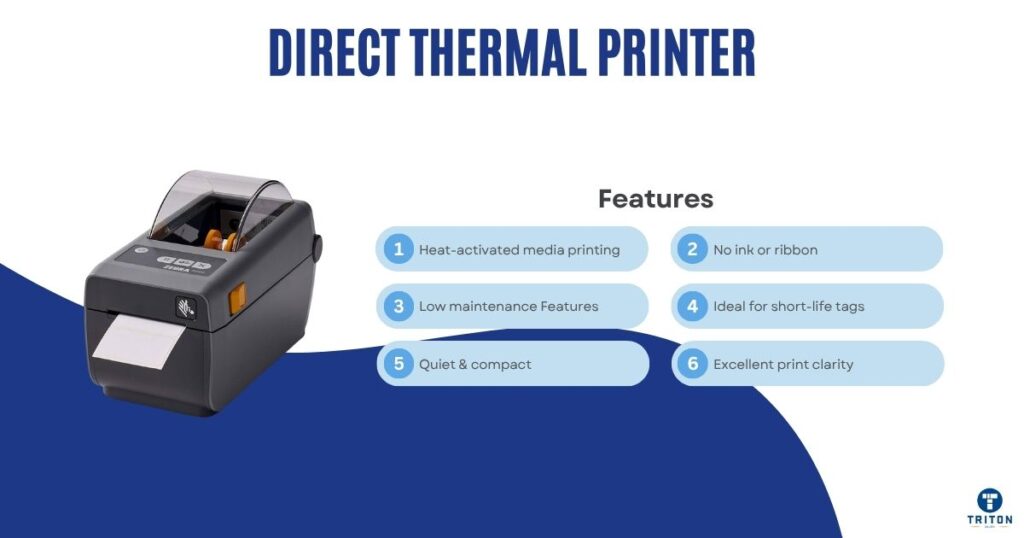

Thermal printers print through controlled heat rather than impact or sprayed ink. They divide into two architectures: direct thermal and thermal transfer.

Direct thermal printers use specially coated media which contains the Leuco dye that imprints under heat. The print head contains a line of resistive elements, each individually addressable. When energised, these elements get heated to 200-300 °C. When the head touches the thermal paper, a chemical reaction is triggered in the dye layer of the paper.

Line density ranges from 203 to 600 dpi, suitable for barcodes, receipts, and tickets. Print speeds are between 150 and 300 mm/s. Since the medium itself is reactive, ribbons or toners are not required. However, output is vulnerable to UV exposure, abrasion, and heat, which shortens archival life to months or a few years. The printer’s reliability is high because there are no consumables beyond media, and maintenance usually involves periodic head cleaning and platen roller replacement.

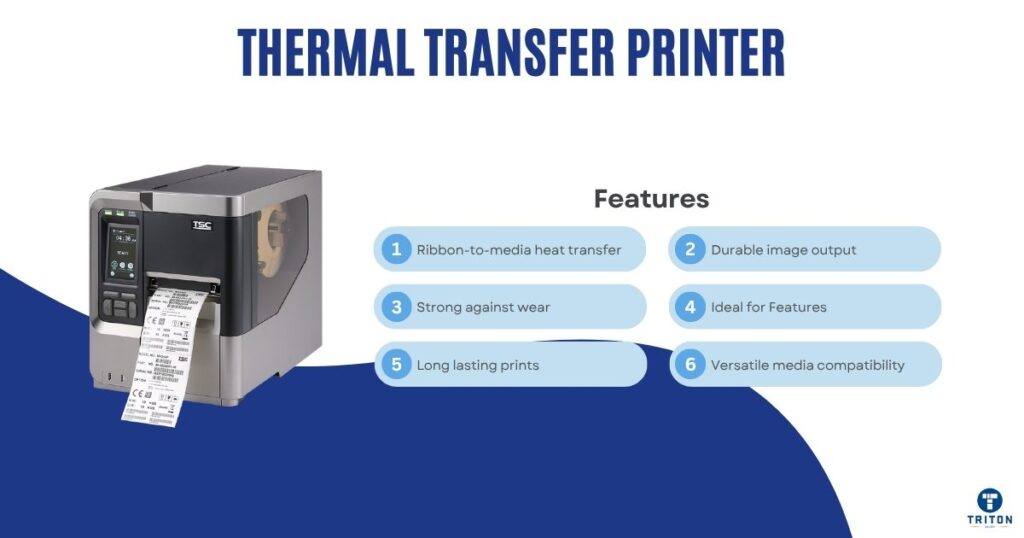

Thermal transfer printers don’t need a thermal printer. Instead, they apply heat through a ribbon coated with solid ink or resin. The resistive head elements selectively melt the coating and bond it to paper, film, or synthetic labels. This method supports a range of print surfaces, including polyester, polypropylene, and vinyl.

The print resolution of the thermal transfer printer is between 200 and 600 dpi. Specialised heads used for printing micro text and 2D barcodes can print 1200 dpi.

Transfer ribbons come in three broad varieties. Wax formulations suit shipping labels. Wax-resin mixes balance, durability and cost. Pure resin ribbons are the most durable and expensive but provide chemical and heat resistance.

Print speed is between 100 and 250 mm/s.

Because the ribbon material transfers to the paper and the paper is not heat sensitive, image permanence is ten plus years under proper storage.

Maintenance focuses on head pressure calibration and ribbon alignment. Industrial units integrate sensors to detect ribbon breaks, end-of-roll status, and media tracking for continuous operation. Thermal transfer systems are used in logistics, laboratory, and asset-tracking environments.

Dye-sublimation printers heat solid dye until it vaporises and diffuses into a coated medium. In photo printing, the medium is polymer-coated paper stock, while in textiles, it is polyester fabric or transfer paper with a receptive polymer layer.

The print head contains hundreds of resistive elements aligned with the media path. Each element generates controlled heat pulses between 180 and 400 °C. The heat converts the dye on the ribbon into gas, which bonds at a molecular level with the polymer surface of the medium. This creates continuous-tone images with smooth gradients and eliminates the pixelation typical of halftone systems.

Photo dye-sublimation units use CMY or CMYO ribbons, with each colour panel yielding a complete image layer. A protective overcoat (the “O” panel) resists UV light, moisture and fingerprints. Print resolution is not defined by dpi but by the thermal head’s control of dye density. The print quality is comparable to photographic detail at 300-600 dpi continuous tone. Output size is 4 x 6 inches in 30-60 seconds. Prints last 20-30 years under archival storage. Media and ribbon are matched in sets, with yields of 100-300 prints per kit. Maintenance involves head cleaning and roller replacement.

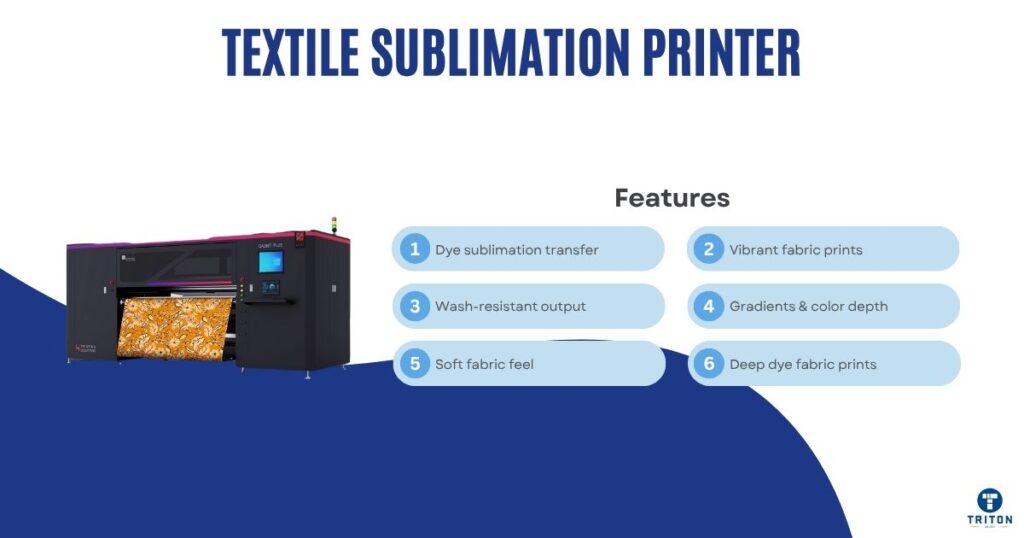

Textile sublimation systems transfer dye onto polyester fabrics using intermediate transfer paper or direct-to-fabric methods. The paper stage receives the sublimated dye image, which is then heat-pressed into fabric at 180-210 °C with pressures of 0.3-0.6 MPa.

Direct systems feed fabric directly under the print head and through heated calenders.

Colour sets extend beyond CMYK. Some standard colours are light cyan, light magenta, fluorescent pigments, and expanded gamut inks such as orange, violet, and green. Some industrial engines integrate up to eight or ten channels, which push achievable gamut coverage above 95% of the “Pantone range.”

Light inks reduce grain in pale tones, while neons deliver high visibility for sportswear and signage. Extended channels allow smooth reproduction of brand colours and gradients that standard CMYK cannot match. Ink chemistry is optimised for polyester fibres, with dispersion stability ensuring continuous runs of 500 metres or more without colour drift.

Outputs range from 1.2 m to 3.2 m in roll-to-roll systems, with 30-70 m² per hour.

Sublimated textiles have a fastness of 50+ wash cycles without fading. Stretch resistance tests show image stability at ~20% elongation without visible cracking. High-performance blends hold integrity beyond ~30% for compression fabrics.

Textile sublimation printer maintenance includes nozzle cleaning, alignment calibration, and replacement of periodic transfer belts and heating elements. Textile sublimation is used in sportswear, signage, and interior décor markets.

Solid ink printers use blocks of solid ink composed of resin-based wax with pigments that are melted and jetted onto a heated drum before transfer to paper. The process does not need liquid cartridges and produces a dense, uniform colour layer.

Ink blocks are melted at around 120 °C, stored in reservoirs, and metered through piezoelectric jets. The image is first written onto a rotating drum, which is kept at a stable temperature, then transferred under pressure to the print medium.

Solid Ink Printers have a 600-1200 dpi resolution with vivid saturation and smooth gradients. Output is smudge-resistant because the ink solidifies quickly on contact with the medium.

These printers require 5-15 minutes to warm up to reach operating temperature. Print speeds are in the 20 to 40 ppm range for office models, with monthly duty cycles of 100,000+ impressions in enterprise units.

Consumables include the solid ink sticks and a maintenance roller coated with silicone oil that prevents offset.

Solid ink printers can use up to 50-90% less energy than their laser counterparts. Laser printers rely on a power-hungry fuser unit to bond toner to paper using intense heat (200°C). Solid ink printers use less energy by melting sticks at ~120°C.

Solid ink prints are less durable because the wax-based ink rests on the paper and is not absorbed into it. This raised ink layer is easily scratched or flakes off with physical contact. The ink is sensitive to heat and softens, smudges, or transfers to other pages if not archived in a temperature-controlled environment.

Solid ink printing is a niche printer used for consistent colour density, low waste packaging, and predictable cost.

Wide-format printers print widths larger than 18 inches up to grand-format systems above 3 metres. They use inkjet heads mounted on precision carriages with linear encoders that maintain registration across oversized substrates.

Applications include signage, posters, CAD drawings, banners, textiles, and printing on thick & rigid materials. Resolutions range between 1200 and 2400 dpi, with minimum droplet sizes of ~3-7 pL for fine detail. Throughput ranges between 30 and 100 m² per hour in office-class units and 500+ m² per hour in industrial systems.

Roll-fed machines feed flexible substrates such as vinyl, photographic paper, backlit films, or coated textiles from spools. Servo-driven pinch rollers maintain tension and prevent skew. Print widths range from 24 inches to 5 metres. Integrated take-up reels wind printed output continuously, supporting long banners or tiled graphics. Drying uses forced air, infrared heaters, or solvent evaporation, depending on ink chemistry.

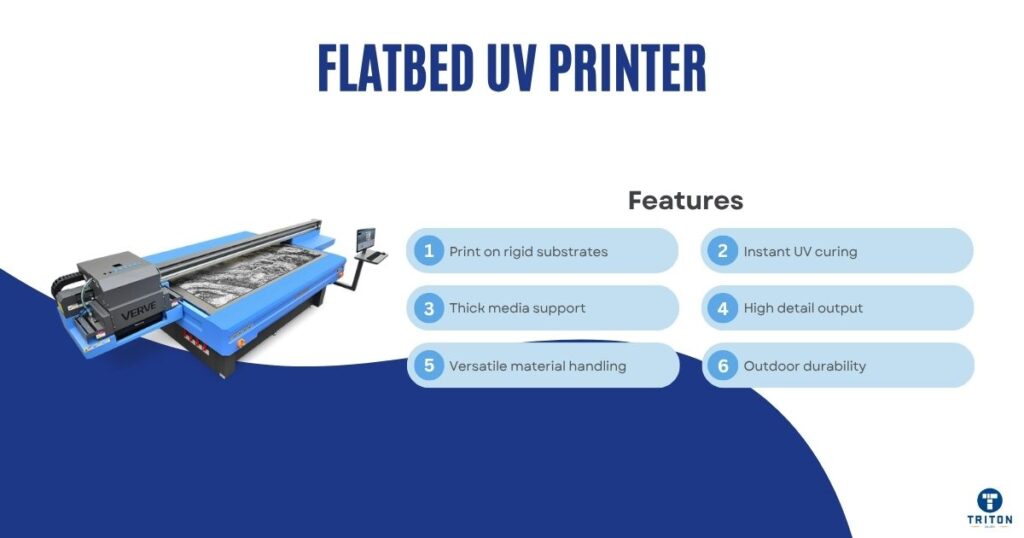

Flatbed printers print high-quality images directly on thick, rigid materials like wood, glass, acrylic, foam board, and metal sheets.

A flatbed printer uses a large, stationary vacuum table to hold the heavy material perfectly still. A print head moves back and forth above the object, spraying UV-curable or solvent inks onto its surface. Powerful lamps are built into the print head to cure (instantly dry) the ink as it is applied, making the finished product immediately durable and ready for handling.

These printers can handle large and thick items, with print beds up to 3 x 5 meters and can print on materials as thick as 50 mm (about 2 inches).

These printers use registration pins and optical cameras to align the image accurately to within ±0.2 mm.

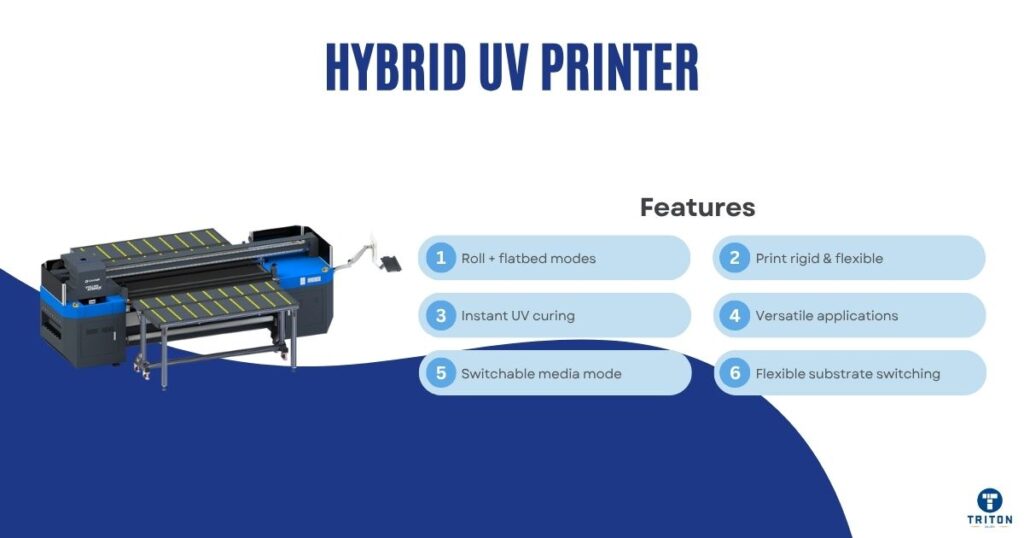

A hybrid printer combines the functionality of both a flatbed and a roll-to-roll system into a single machine. This dual capability lets you print directly onto rigid panels, such as acrylic and wood, and produces high-quality graphics on flexible substrates like vinyl banners. The key insight is the enhanced return on investment; you capture a broader range of jobs without the capital outlay and floor space required for two separate printers.

Switching between production modes is a straightforward process. For rigid media, you configure the machine with its flatbed tables. To print on flexible rolls, you engage the integrated pinch-roller assemblies. This convertible design ensures you always use the optimal setup for the specific media type, minimising downtime between jobs.

These systems can print media between 2 and 3.2 metres and resolutions up to 1200 dots per inch (DPI). Throughput is between 60 and 200 square metres per hour. High-end models print 400+ m²/hr.

Latex ink contains 60-70% water, 25-30% polymer solids (Acrylics/acrylic esters (e.g. butyl acrylate, methyl methacrylate), and tiny amounts of volatile organic compounds (e.g. C₂-C₄ alcohols, esters, hydrocarbons, and ethers).

When jetted onto a substrate, radiant heat and airflow evaporate the liquid, causing the nanoparticles to coalesce into a continuous film that encapsulates the pigment.

Latex printers use heating elements at 60-110 °C to accelerate evaporation, while forced air ensures uniform drying across wide media.

The result is a durable, scratch- and environment-resistant print.

Print widths span 1.3 to 3.2 metres in roll-to-roll designs. Resolutions reach 1200 dpi, and droplet sizes are below ~5 pL for smooth gradients. Typical throughput is 20-40 m²/hr in high-quality modes and over 100 m²/hr in production settings.

Popular substrates are vinyl, wallpaper, textiles, and coated papers. Latex systems are used for banners, vehicle wraps, wall coverings, and soft signage.

Digital presses are used for short to medium print runs where flexibility and turnaround speed matter more than the lower cost of plate-based offset printing. These systems produce consistent colour, high resolutions, and support variable data workflows without interrupting throughput. Two common digital press types are the commercial inkjet presses and electrophotographic presses.

Commercial inkjet presses use piezoelectric or thermal inkjet heads. Heads are mounted on arrays across a continuous or sheet-fed media transport system.

Ink drop sizes range between 2 and 6 pico Litre for coated stocks and 10 and 20 pico Litre for uncoated substrates.

Multipass screening is a process where the print head makes several passes over the same area to build the image with greater precision, and resolutions reach 1200 x 1200 dpi.

Throughput of commercial inkjet presses ranges from 75 to 300 A4 impressions per minute in sheet-fed engines, while web-fed units print over 300 metres per minute.

Advanced dryers integrate hot air and infrared to stabilise ink penetration. Duty cycles exceed 20 million pages monthly. Integrated spectrophotometers monitor colour density inline, and software applies ICC calibration automatically. Applications include catalogues, magazines, transactional statements, and personalised direct mail.

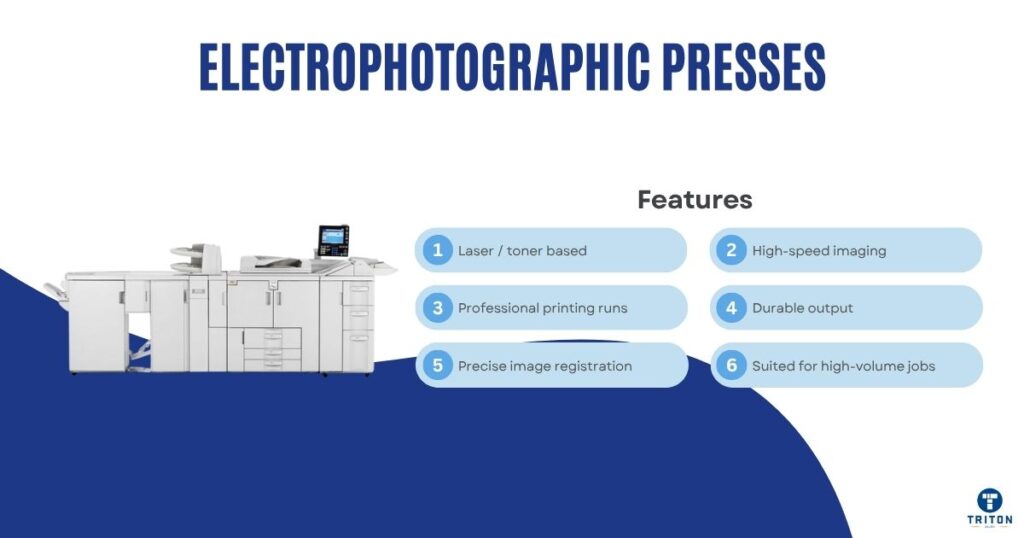

Electrophotographic presses, essentially high-end laser printers, use light and static electricity to create a print. First, a laser or LED creates an invisible image with a static charge on a rotating drum.

This charged image attracts fine powder ink (4 and 6 µm in size), known as toner, which sticks to the drum.

Finally, the paper rolls against the drum to pick up the toner, and the page passes through hot rollers that fuse the powder permanently onto the surface.

This process produces smooth gradients and sharp type at resolutions of 2400 dpi, often employing advanced screening options like stochastic halftoning.

The most common sheet-fed formats support substrate weights between 60 and 400 gsm and paper sizes up to B2 (500 x 707 mm). Production speeds for these presses typically reach 100-150 A4 pages per minute.

Duty cycles are between 2 and 5 million impressions monthly. Inline finishing modules trim, fold, and bind directly after imaging. Variable data integration supports high-volume personalised jobs.

Electrophotographic presses excel at consistent colour reproduction across long runs and provide near-offset quality without the setup cost of plates.

3D printers construct physical objects by depositing or solidifying material layer by layer according to a digital model. Each layer represents a horizontal cross-section of the design, generated by slicing software that converts a 3D CAD file into layers. Additive manufacturing is the opposite of processes such as cutting or milling, which are “subtractive”.

3D printers can create parts with complex internal geometries that are impossible to machine.

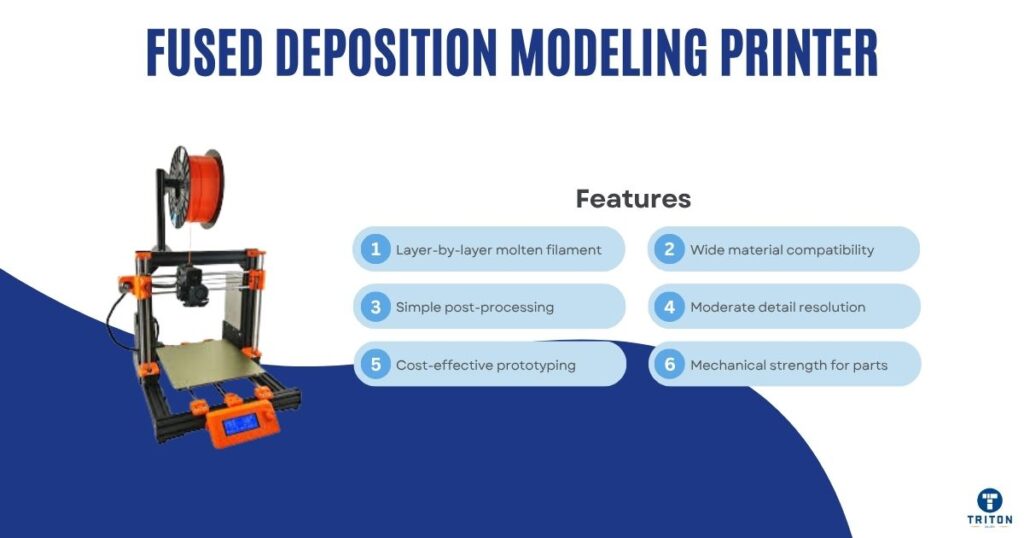

FDM printers extrude thermoplastic filaments like PLA, ABS, PETG, or nylon through a 90-260 °C hot nozzle. The nozzle moves in the X-Y plane, depositing melted material on a build platform while the Z-axis raises it layer by layer.

Layer heights range from 0.05 to 0.3 mm, defining resolution and surface finish. Heated beds and enclosed chambers prevent warping and improve layer adhesion.

Print speeds depend on layer thickness and nozzle diameter, varying from 40 to 150 mm/s. FDM output is dimensionally stable within ±0.1 mm and is suitable for prototypes, jigs, and low-volume production parts.

Multi-extruder variants can print soluble supports or multiple colours. Maintenance includes nozzle cleaning, filament drying, and platform levelling.

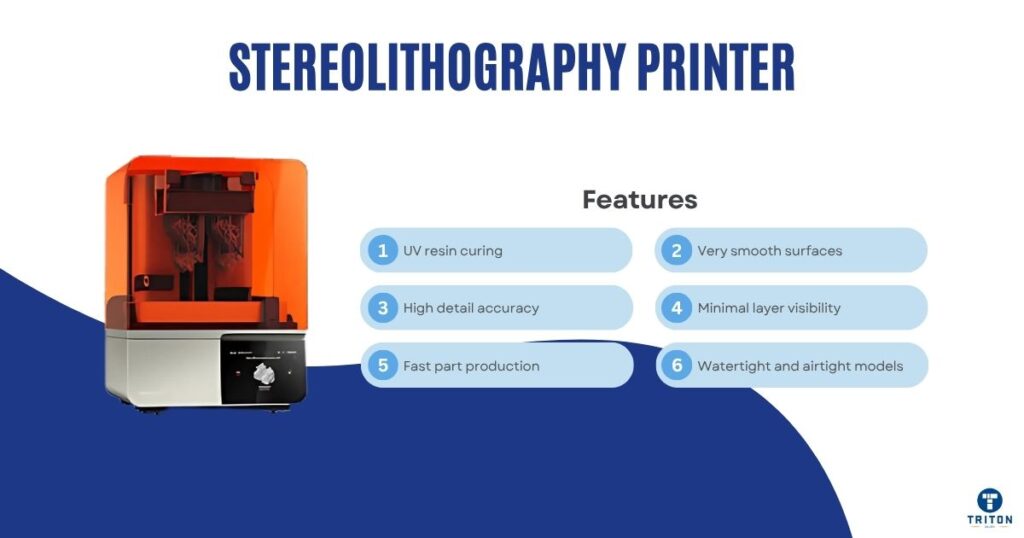

Stereolithography (SLA) builds by hardening liquid plastic with a focused light source. The process begins with a tank, or vat, filled with a liquid plastic called a photopolymer resin, which solidifies when exposed to ultraviolet (UV) light. Inside this vat, a build platform is lowered into the resin, leaving just a thin layer of liquid on top.

A high-precision UV laser or a digital projector shines onto this layer, tracing the shape of the object’s first cross-section. The UV light triggers a chemical reaction called polymerisation, which turns the exposed liquid resin into a solid layer. The build platform then moves down a fraction of a millimetre to allow a new resin layer to flow over the previous one.

This process is repeated, with the light drawing and hardening each layer.

Layer thickness ranges from 25 to 100 µm, which can produce fine detail and smooth surfaces. Build area is ~ 120 x 68 x 150 mm for desktop models to ~ 800 x 800 x 400 mm for industrial units. Typical print accuracy is ±0.05 mm.

After printing, parts require washing in isopropyl alcohol and curing under UV to reach full strength. SLA resins differ in tensile strength (30-80 MPa), heat deflection temperature (45-120 °C), and flexibility, allowing engineering, dental, or jewellery applications.

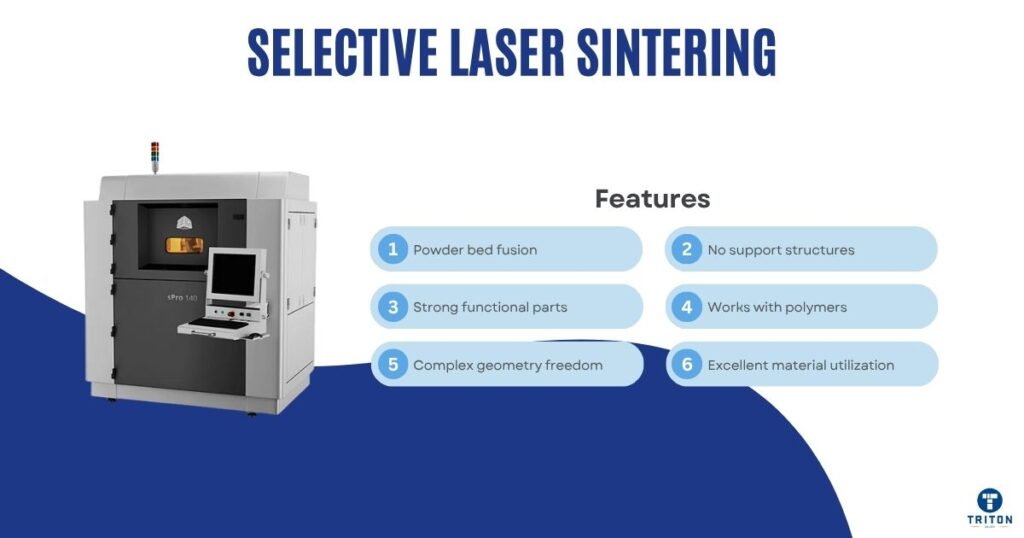

SLS printers fuse powdered thermoplastics like PA11, PA12, or TPU with a high-power infrared laser.

A recoater spreads a thin powder layer (0.06-0.15 mm thick) over the build platform, and the laser sinters each cross-section at temperatures near the polymer’s melting point.

Unfused powder supports the structure, so no separate support material is needed.

Typical dimensional accuracy is ±0.1 mm, and surface roughness is in the Ra 10-20 µm range. Part strength is 80-90% of injection-moulded equivalents.

Printer chambers range from 150 x 150 x 250 mm in benchtop systems to over 700 mm in industrial machines. Post-processing includes bead blasting, dyeing, or infiltration for improved appearance. SLS is used for end-use components, housings, medical braces, and aerospace prototypes.

The build rate across all 3D printing types depends on layer height, infill density, and motion system. Industrial machines achieve 20-100 cm³/hr material deposition, while large-format SLS systems exceed 1 litre/hr. Filament, resin, or powder costs vary from $20 per kg for PLA to $300 per litre for engineering resins. 3D printing’s strength lies in design freedom, minimal waste, and rapid iteration, making it essential for prototyping, customised products, and distributed manufacturing.

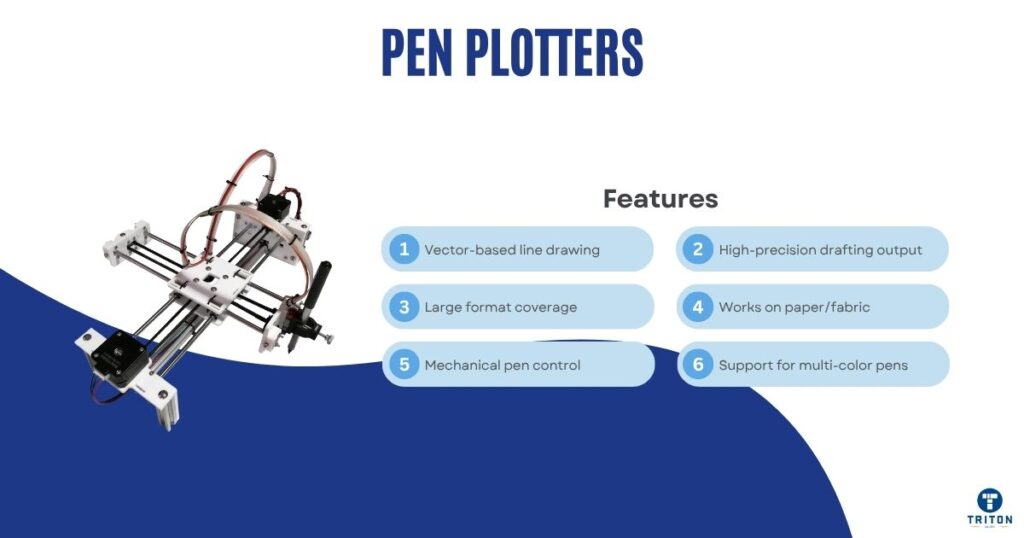

Plotters draw images using controlled pen movement instead of spraying or fusing ink. They interpret vector data. Vector data is a mathematical description of lines, curves, and other shapes. Plotters can draw precise technical drawings.

Plotters’ heart is a microprocessor that translates the X-Y coordinate data into motor commands that move the pen in the X-Y plane while lifting or lowering it as needed.

Stepper motors and optical encoders are used in the feedback loop for positioning accuracy, typically ±0.05 mm. Resolutions range from 1000 to 4000 steps per inch. Modern plotters can produce sharp, continuous lines without pixelation.

Modern flatbed and drum plotters use servo drives for smoother motion and faster throughput.

Drum units wrap the paper around a rotating cylinder while the pen moves laterally, for continuous long-format plotting.

Flatbeds fix the sheet and move the pen gantry across its surface. They can plot up to A0 (841 x 1189 mm).

Plot speeds are in the 200 to 600 mm/s range, with professional systems exceeding 1000 mm/s. Multi-pen carriages swap between ink types or line widths automatically.

Digital pen plotters now use liquid ink, fibre-tip, or technical pens with controlled flow rates. Output quality remains consistent because mechanical pens maintain fixed stroke widths rather than relying on dot density.

These systems can plot on media such as drafting film, coated paper, or vinyl.

Maintenance includes pen calibration, platen cleaning, and periodic alignment checks to maintain dimensional accuracy.

Although large-format inkjets are replacing plotters, pen plotters are still used in specialist design, engineering, and archival printing where vector precision is required.

They are used for circuit masks, architectural schematics, cartographic overlays, and calibration templates that demand exact linearity. Their non-impact operation eliminates vibration-induced distortion, and mechanical tolerances allow line repeatability below 0.1 mm across metre-scale drawings.

Label, barcode, and receipt printers are used for fast and reliable text & code output in commercial and industrial settings. They use thermal technologies – direct thermal for short-term receipts and thermal transfer for long-lasting labels – but integrate precision mechanics and sensors for high-volume workflows.

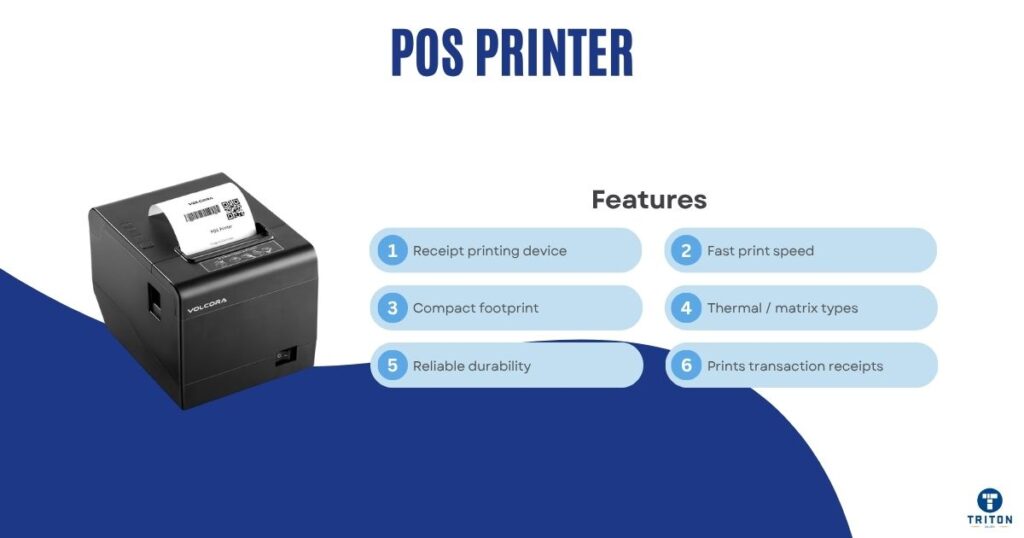

Point-of-sale printers print receipts, tickets, and vouchers at transaction counters. They use direct thermal printing at resolutions of 203-300 dpi and speeds of 150-350 mm/s.

Compact designs include auto-cutters for continuous rolls up to 80 mm wide. Life expectancy is ~150 km of printed media or 1.5 million cuts. Connectivity includes USB, Ethernet, Wi-Fi, and serial interfaces for integration with retail systems.

Advanced models feature QR or barcode rendering, paper-saving modes, and anti-jam feeders. Most POS printers use less than 60 W during peak operation.

These systems operate reliably for five to seven years under daily use.

Industrial barcode printers produce durable identification labels, asset tags, and compliance stickers. They mostly use thermal transfer print technology (thermal ribbon printing) with 200-600 dpi print resolutions, and support linear & 2D symbologies such as Code 128, QR, and Data Matrix.

Advanced thermal heads maintain consistent heat distribution to keep barcode contrast ratios above ANSI grade B, ensuring scanner readability even in dusty or low-light environments.

Typical throughput is between 4 and 14 inches per second (100-350 mm/s). Ribbon widths come in standard label formats – typically 100-150 mm – and use wax, wax-resin, or pure resin formulations. Label longevity exceeds ten years with resin ribbons under controlled storage.

Printheads deliver 30-50 km of duty before replacement, and metal chassis construction withstands harsh warehouse and production conditions.

Printers in this class handle label rolls of up to 8 inches in diameter and integrate media sensors for gap, black-mark, or continuous form detection.

Interfaces include USB, serial, parallel, and industrial Ethernet protocols such as Modbus and TCP/IP.

Industrial barcode printers have embedded controllers that, amongst other things, support Unicode fonts and scalable vector graphics to print logos and international text. Firmware includes real-time clock functions for time-stamped barcodes and diagnostic logs for predictive maintenance.

Maintenance cycles involve platen roller cleaning every 20 km of output and head replacement.

High-performance systems have RFID encoding modules and can also print smart labels for supply chain tracking.

Proofing printers reproduce colour output that matches the final production press. They are used in packaging, publishing, photography, and prepress environments where colour accuracy, repeatability, and predictability are mandatory.

The most advanced units are continuous-flow inkjet proofers, also known as Iris proofers, which use a liquid-ink delivery system designed for fine tonal control.

Continuous-flow inkjet proofers work by forcing a constant stream of ink through micro-nozzles at pressures up to 400 kPa. The nozzles vibrate at 100-150 kHz to generate millions of uniform droplets per second. An electrostatic deflection plate steers selected droplets to the paper while unused ones recirculate into the reservoir.

Droplet sizes average 5-20 pL, producing 1200-2400 dpi resolutions with continuous-tone gradation rather than discrete dot patterns. When calibrated, colour density variation stays below ΔE 1.0 between consecutive proofs.

Proofing systems use extended ink sets beyond CMYK, typically six to twelve channels. These include light cyan, light magenta, orange, green, violet, and grey, achieving 95-98% Pantone gamut prints.

Print media for proofing printers are high-grade proofing paper, polyester film, and engineered coated stock.

These printers use advanced RIP software to linearise output curves, convert spot colours through ICC-profiled workflows, and maintain consistency between proofs and press sheets. They also have a built-in spectrophotometer to measure the print with a calibration chart and adjust ink density and hue: an environmental sensor monitors environmental temperature and humidity, and is part of the colour control feedback loop.

Since these printers prioritise accuracy, the average print speeds are around 2-8 A3 sheets per minute. Print width ranges from 17 to 44 inches. Maintenance includes scheduled head purging, fluid replacement, and calibration routines that sustain line density uniformity under ±0.5% deviation.

Hybrid and speciality printers bridge gaps between traditional printing and surface printing. They print on materials that standard inkjets, lasers, or thermals cannot handle – surfaces like ceramics, glass, textiles, metal, and wood.

Ceramic printers jet mineral-based pigments suspended in oil or water on glazed tiles or porcelain. The printed pattern is fired in kilns between 700 °C and 900 °C, which fuses pigment into the glaze layer.

Resolutions reach 720-1440 dpi, and pigment particle sizes average 1-3 µm, which gives smooth tonal control.

Industrial systems operate on conveyor-fed platforms and print over 50 m²/hr, producing architectural panels and decorative tiles.

Advanced ceramic printers use colour management software to match Pantone or RAL shades under high-temperature firing conditions.

Glass printers use UV-curable or ceramic frit inks to print directly on float, tempered, or laminated glass.

The process begins with pre-cleaned glass moving under precision gantries.

Drop sizes of 10-20 pL form resolutions up to 1440 dpi. LED lamps instantly solidify ink for UV-curable systems, forming durable, abrasion-resistant layers.

Ceramic-frit glass printers follow a thermal route: printed glass passes through furnaces at 600-700 °C, melting inorganic pigments into the surface.

Typical production speeds reach 20-40 m²/hr. Printed glass retains 90% visible light transmittance while adding full-colour imagery. Applications include façades, automotive glazing, and decorative interiors.

Textile and fabric printers print directly on natural and synthetic fabrics. Ink chemistry varies by fibre – reactive inks for cotton, acid dyes for silk, pigment inks for blended fibres, and disperse dyes for polyester.

Printheads deliver 600-1200 dpi resolutions with droplet volumes between 4 and 12 pL. Belt-fed transport ensures fabric tension control within ±0.1%. Production speeds range from 40 m²/hr for high-quality fashion prints to 800 m²/hr in industrial roll-to-roll machines.

Post-processing involves steaming at 100-180 °C, washing, and drying to fix colours permanently. Colour yield exceeds 90% of the input gamut, and wash-fastness ratings meet ISO 105-C06 standards.

Speciality printers push print technology beyond paper. They combine mechanical precision with material science, turning glass, ceramics, and fabrics into durable, high-resolution canvases for design and industry alike.

In closing, printing is a spectrum of technologies, each built for a role: speed, durability, colour, substrate handling, or economy. Use the sections above as your guide to choose wisely.

If you’re ready to explore real-world hardware and supplies across these technologies, check out Triton Store’s extensive range of thermal printers and accessories.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below