RFID readers serve as the central communication hub in automated identification systems. These devices transmit radio frequency signals and receive data from RFID tags without requiring physical contact or line-of-sight.

Manufacturing facilities, warehouses, hospitals, and retail stores utilise RFID readers to track inventory, monitor assets, and manage supply chains in real-time.

The technology eliminates manual scanning. It enables simultaneous reading of hundreds of tags within milliseconds.

Businesses implement RFID systems because readers provide data accuracy of 95-99% compared to 60-70% with barcode scanning.

Understanding how readers function, which components drive their operation, and how electromagnetic principles govern communication becomes necessary for organisations deploying RFID solutions.

RFID operates through the automatic identification and capture of data. The system uses electromagnetic coupling in the radio frequency spectrum to transfer data between tags and readers. Unlike barcodes, which require scanners to read printed codes, RFID works through radio waves and can penetrate materials such as cardboard, plastic, and fabric.

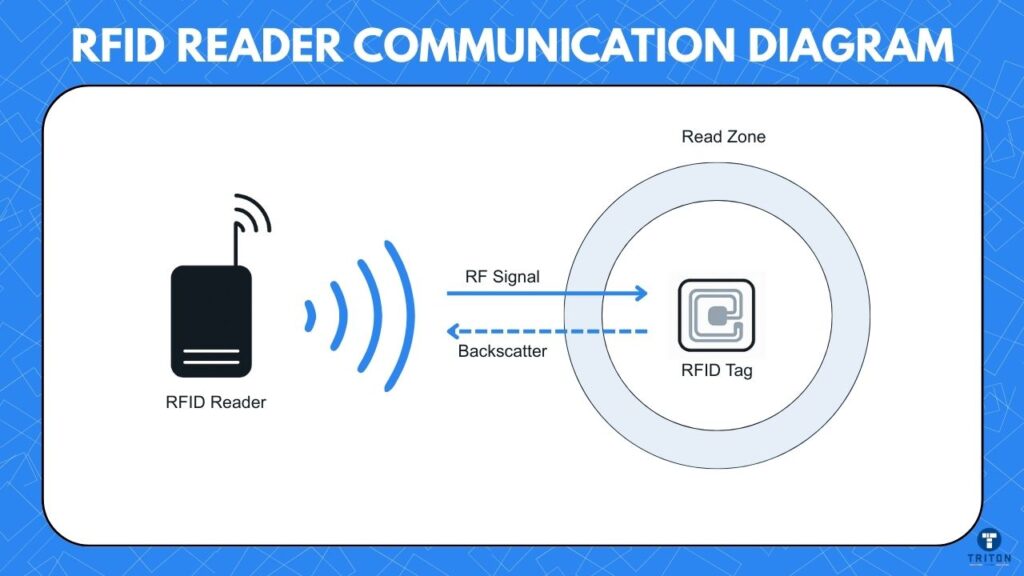

Radio waves initiate the process. The reader transmits them into a defined read zone, and tags within this zone capture the electromagnetic energy. The tag then modulates and reflects a portion of the signal to the reader’s antenna, a process called backscatter communication. The reader converts these modulated signals into data and forwards the information to backend systems.

This bidirectional communication happens fast. Within milliseconds, in fact. A reader can identify, track, and manage hundreds of tagged items simultaneously without human intervention.

RFID technology enables real-time visibility into asset location, inventory levels, and item status. Manufacturing lines, distribution centres, and retail environments deploy RFID readers at fixed locations or equip workers with portable devices to capture data wherever needed.

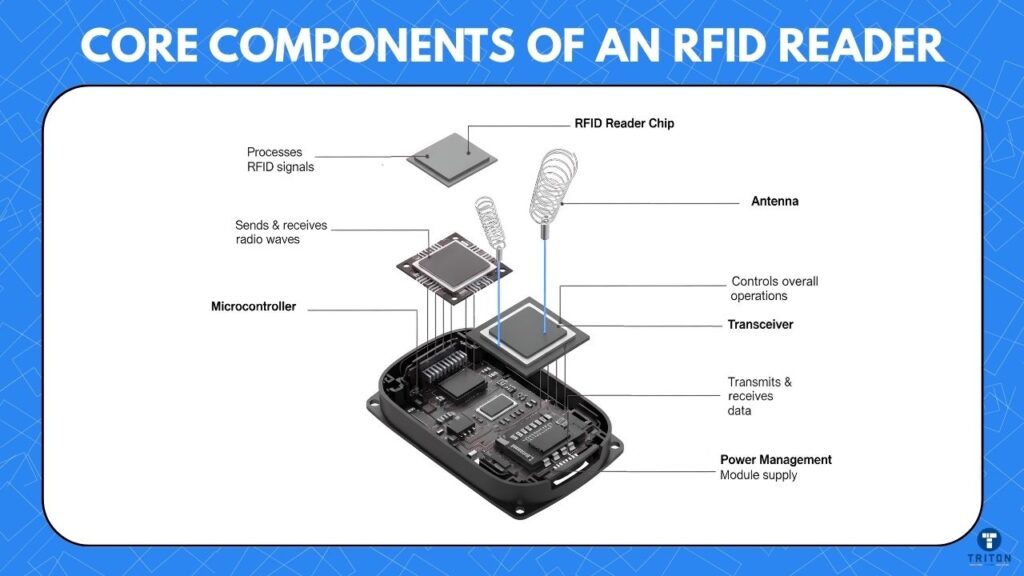

Five key components work together inside RFID readers to enable communication between tags.

Radio frequency signals? The RFID reader chip generates them. This integrated circuit manages all RF communication with tags, generating signals, processing incoming transmissions, and decoding information encoded on the tags. Manufacturers design reader chips for specific frequency bands, including low frequency, high frequency, and ultra-high frequency. Each requires antenna designs matched to that frequency range.

The antenna does two things.

It transmits electromagnetic waves that power passive tags. It receives the backscattered signals that tags return. The antenna’s gain, polarisation, and design determine the reader’s range, speed, and accuracy.

Fixed readers often connect to multiple antennas-2, 4, or 8 ports-to cover larger read zones, and antenna selection affects whether the system reads tags reliably at different orientations.

Coordinating the reader’s activities is the responsibility of the microcontroller unit. This processor receives data from the RFID chip, manages communication with computers or mobile devices, and controls the reader’s operating parameters. The microcontroller communicates with the RFID chip through serial interfaces such as I2C, SPI, or UART.

Signal modulation and demodulation? That’s the transceiver’s job. It sends electromagnetic signals to tags and receives their responses, managing the encoding and decoding of information between the reader and tag.

Power management systems supply electricity to all components. Fixed readers typically use Power over Ethernet or AC adapters, handheld readers rely on rechargeable batteries, and USB readers draw power directly from computer ports.

Readers generate an alternating magnetic field or radio beam to initiate tag communication. When activated, the reader continuously broadcasts an electromagnetic field containing a handshake protocol.

Passive RFID systems, which represent the majority of deployments, use the reader’s electromagnetic field to power the tags. The passive tag’s antenna captures this RF energy. It converts it into an electrical current, which powers the tag’s integrated circuit and enables it to transmit the stored data back to the reader. The process occurs without the need for batteries in the tag.

Active RFID systems work differently. Active tags contain batteries that power continuous signal transmission. These tags operate at ranges of up to hundreds of metres, compared to the few metres achieved by passive systems.

Backscatter communication forms the core mechanism for passive RFID. How does it work? Tags modulate the reader’s electromagnetic field by alternating between two states-reflecting or absorbing portions of the signal-and this modulation encodes the tag’s stored information without requiring the tag to generate its own radio transmission. The reader’s antenna captures these variations in the reflected signal and converts them back to digital data.

The read cycle happens in milliseconds. UHF readers can interrogate and receive data from over 1,000 tags per second. This speed enables applications such as pallet verification at dock doors, where forklifts move tagged items through portals at normal speeds whilst readers capture every tag ID.

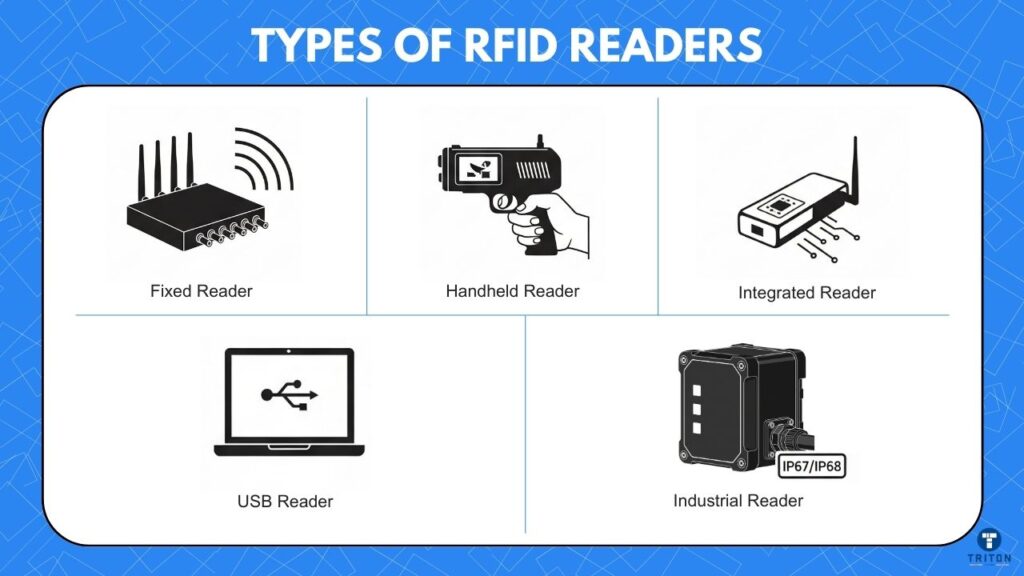

RFID readers are categorised into five groups based on form factor and application requirements.

Fixed RFID readers are mounted permanently at specific locations such as doorways, conveyor belts, or warehouse portals. These stationary devices provide continuous, automated monitoring of items passing through their read zones. Fixed readers support multiple antenna connections-typically 2, 4, or 8 ports-to cover vast areas or monitor numerous access points from a single device. They connect to enterprise networks via Ethernet or Wi-Fi and operate continuously, 24/7, without requiring human intervention.

Portable scanning for field operations. That’s what handheld RFID readers offer. These battery-powered devices let workers scan tags from any location. Warehouses use them for cycle counting, receiving verification, and location audits. Retail stores use them for stocktakes and to locate items.

Integrated readers combine the reader electronics and antenna in a single compact unit. These devices are suitable for applications where space constraints prevent separate reader and antenna installations.

USB readers plug directly into a computer’s USB ports for desktop applications. Small. Simple. These devices read tags presented at close range and send data directly into software applications.

Industrial readers feature ruggedised enclosures designed for harsh environments. Manufacturing facilities, outdoor installations, and chemical plants require industrial readers with IP67 or IP68 ingress protection ratings.

The operating frequency determines a reader’s range, data transfer speed, and compatibility with various environments.

Low-frequency readers operate at 125-134 kHz and provide read ranges up to 10 centimetres. LF systems excel near metals and liquids because low-frequency signals penetrate these materials better than higher frequencies. Access control, animal identification, and industrial automation use LF readers.

High-frequency readers operate at 13.56 MHz. Read ranges? Up to 1 metre. HF systems transfer data faster than LF whilst maintaining reasonable performance near metals. Library systems, ticketing gates, contactless payment terminals, and smart cards rely on HF readers.

Ultra-High Frequency readers operate in the 860-960 MHz range and deliver read ranges up to 12 metres. UHF systems can read over 1,000 tags per second without requiring a line of sight.

Supply chain logistics, retail inventory, and pallet tracking deploy UHF readers because the long range and high throughput enable automation at scale. However, UHF signals reflect off metals and are absorbed by liquids.

Frequency selection depends on read range requirements, tag density, data transfer speed needs, and environmental factors.

RFID readers deliver benefits that drive adoption whilst facing constraints that affect deployment decisions.

Readers scan tags without line-of-sight. Unlike barcode scanners that require visible printed codes, RFID readers can detect tags through cardboard, plastic, and fabric.

Simultaneous multi-tag reading? It lets readers scan hundreds of tags per second. A single reader positioned at a warehouse door can capture every item on a pallet as a forklift drives through.

Read ranges extend from centimetres for LF systems to 12 metres for passive UHF systems, with active systems reaching hundreds of metres. Tags support read/write operations, allowing readers to update tag memory in real-time.

The limitations matter too. Initial costs are higher than those for barcodes-fixed readers cost $2,000 to $8,000, handheld units cost $1,000 to $4,500, and passive tags start at $0.10 each for basic tags.

Environmental interference affects performance. Metals reflect UHF signals and liquids absorb them, reducing read accuracy. Tag collision occurs in high-density environments when hundreds of tags respond simultaneously.

Retail operations use RFID readers for real-time inventory visibility. The technology reduces retail stockouts by 20-30%.

Healthcare facilities use RFID readers to track medical equipment, monitor patient location, and manage pharmaceutical inventory. Hospitals can reduce equipment loss by up to 15% with RFID.

Logistics operations utilise readers at dock doors to automatically verify shipments, providing end-to-end traceability.

Manufacturing plants install fixed readers along production lines to monitor work-in-progress, resulting in a reduction of downtime by up to 25%.

RFID readers operate through electromagnetic communication between reader components and wireless tags.

The reader chip generates RF signals. The antenna transmits and receives electromagnetic waves. The microcontroller manages data processing, and the transceiver handles signal modulation.

Passive systems use backscatter communication where tags modulate the reader’s signal.

Active systems employ battery-powered tags that transmit at extended ranges. Different reader types suit various needs-fixed readers provide continuous monitoring, handheld readers offer portable scanning, and USB readers serve desktop applications.

Operating frequency affects performance: LF works near metals, HF provides medium range, and UHF delivers long-range reading. Understanding reader architecture, operating principles, and frequency characteristics enables organisations to select appropriate technology and deploy systems that deliver measurable improvements.

Strengthen your automation, improve traceability, and support real-time visibility with the right equipment. Visit Triton Store for proven solutions.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below