Choosing the correct label is not just a design decision – it’s a performance requirement. In industries where labels face water, chemicals, UV, temperature variations, and rough handling, material selection directly affects product integrity, traceability, and regulatory compliance.

This article explains the technical and regulatory differences between waterproof and water-resistant labels and how label construction – facestock, adhesive, coatings, and print method – affects durability in wet and harsh environments.

You’ll learn how performance is validated using standards like BS 5609, UL 969, ASTM D1000, and why most paper-based labels fail when fully exposed to water.

We also compare cost trade-offs, environmental limits, chemical compatibility, and use cases across sectors like food packaging, logistics, pharma, industrial tools, and marine equipment.

Waterproof and water-resistant labels offer different levels of moisture protection. These terms are not interchangeable and directly affect label performance in wet conditions.

Waterproof labels are made from synthetic materials such as polyester or polypropylene. They use water-repellent inks such as HP Durable Black, Epson DURABrite, or Zebra 5095 Resin, and adhesives like 3M 9671 or Avery Dennison S8025. Waterproof labels resist complete immersion and prolonged moisture exposure.

Waterproof labels lack a single, label-specific standard. True moisture resistance for pressure-sensitive labels is demonstrated via BS 5609, which certifies marine immersion and abrasion performance of the complete label system over 90 days in saltwater, and UL 969, the global standard for durable marking and labelling systems that includes humidity, immersion, and abrasion testing.

Benchmarks such as ASTM D1000 (peel strength after water or chemical exposure) and ASTM D543 (chemical‐resistance testing) define industrial label performance. Other ISO standards (e.g. ISO 15184, ISO 6425) do not apply to label water resistance and should be excluded in this context.

On the other hand, Water-resistant labels are made using materials such as gloss-coated paper, matte-coated paper, and paper treated with water-resistant varnish or lamination. These coatings help resist light splashes and brief exposure to moisture. The adhesives used are permanent but not waterproof, meaning they hold under damp handling but can fail with prolonged contact.

Examining how these layers are built and respond to environmental exposure is necessary to understand the difference between water-resistant and waterproof labels.

The facestock is the uppermost label layer where print is applied and is the primary surface exposed to moisture and abrasion. Its material composition determines how the label performs under wet conditions.

Water-resistant labels use coated or treated paper. These papers are engineered with surface layers – such as clay, calcium carbonate, or polyethylene – that reduce water absorption and improve ink anchorage.

Some variants use wet-strength additives that help maintain fibre integrity under moisture exposure.

While these papers can withstand some contact with water, they degrade under prolonged and repeated exposure. Moisture entering through scratches or edges leads to swelling, delamination, and print failure.

Waterproof labels use non-absorbent synthetic facestocks like polypropylene, polyester, or vinyl, which are dimensionally stable and do not retain water, even after extended submersion.

Alternative constructions such as Tyvek (spunbonded polyethylene) and Teslin (microporous polyolefin) offer additional durability due to their closed-cell or inert structures.

Unlike coated paper, synthetic facestocks protect moisture through material properties rather than surface treatment. For a label to be classified as waterproof, the facestock must be inherently impermeable to water.

The adhesive secures the label to the surface of the container or product. Its moisture resistance determines whether the label will stay in place when wet.

Water-resistant labels use rubber-based or acrylic adhesives. These work well under dry or mildly damp conditions but break down if exposed to extended moisture or full immersion.

Waterproof labels use solvent-based acrylic or emulsion adhesives that not only resist water, but also chemicals, UV light, and temperature changes. These are tested to standards like BS5609 and ASTM D1000 for long-term performance in marine and industrial environments.

A topcoat or overlaminate is an optional layer that protects the printed surface from abrasion, chemicals, and water. It helps keep text readable when exposed to moisture.

Water-resistant labels may use a light varnish or thin acrylic, polyurethane, or water-based compound coatings. These offer limited protection and can wear off, exposing the absorbent paper beneath.

Waterproof labels use durable laminates made from polyester, polypropylene, or vinyl, or chemical coatings based on UV-cured resins or solvent-based polymers.

These layers work with waterproof inks such as UV-cured, solvent-based, or thermal transfer inks to prevent smudging or lifting even after soaking.

The release liner is the backing that covers the adhesive until the label is applied. It is usually made from paper or plastic film, such as polyethylene or polyester, and coated with silicone for easy removal. While it does not affect water resistance, it must stay stable during storage, especially in humid conditions, to ensure proper adhesive performance during application.

Pressure-sensitive adhesives (PSAs) used in water-resistant and waterproof labels differ in how they respond to moisture, temperature, and surface energy. Adhesive failure is one of the most common reasons for label degradation in wet environments.

Rubber-based adhesives have high initial tack and rapidly bond to porous and low-energy surfaces. Their performance depends on temperature and humidity control. These adhesives are susceptible to softening under heat and loss of cohesion in cold or damp conditions. Rubber formulations are not chemically crosslinked and are vulnerable to water ingress over time. They are unsuitable for long-term wet exposure and for immersion or high-humidity applications.

Acrylic adhesives, especially emulsion-based variants, have better resistance to moisture and gradual temperature shifts. They have stronger long-term adhesion and resist oxidation, UV light, and plasticisers.

However, when exposed to continuous moisture, most water-based acrylic PSAs begin to lose integrity. Extended contact with water leads to softening, edge lift, or adhesive failure. These adhesives are not certified under BS 5609 Section 2, which requires labels to remain adhered after 90 days in saltwater.

Solvent acrylic adhesives perform better in high-humidity or chemically aggressive environments but are typically reserved for waterproof constructions.

Water-resistant adhesives are not tested under ASTM D543 (chemical exposure), ASTM D1000 (peel and shear retention), or UL 969 (durability under heat, humidity, and cleaning). Without this validation, they should not be used in immersion, freeze-thaw cycling, or direct chemical contact applications.

Waterproof labels use high-performance adhesives designed for extended exposure to water, chemicals, and temperature cycling. The most common class is solvent-based acrylic PSAs, which form strong, chemically resistant bonds on various substrates.

These adhesives are hydrophobic and maintain adhesion under immersion, power washing, and exposure to oils or fuels. Many are tested to BS 5609 Section 2, which requires the adhesive to retain bond strength after 90 days in saltwater.

Examples include Avery Dennison’s S333 adhesive, which bonds to polyethylene, glass, painted metal, and powder-coated surfaces. It has a minimum application temperature of -4 °C and a service range from -40 °C to +149 °C. Labels using this adhesive comply with marine-grade requirements for chemical drums and export logistics.

Some waterproof adhesives also use high-solids emulsions with crosslinking agents that improve moisture and heat resistance.

Both waterproof and water-resistant labels support high-resolution printing, but the materials and print methods used create differences in durability and clarity.

Water-resistant labels are printed on coated paper using inkjet, laser, or flexographic methods. The degree of water resistance depends on the print process and the top coating.

Inkjet printing uses water-based or pigment-based inks.

Without a topcoat, these inks smudge and bleed on contact with moisture. Coated papers for inkjet include absorbent layers that fix the ink beneath the surface, improving short-term water resistance. However, when exposed to water, edge penetration or abrasion can still lead to print degradation.

Laser printing fuses dry toner to the label surface using heat. This produces a more water-resistant, heat-stable coated paper. However, water can lift the image from the substrate if the toner layer is scratched or the coating degrades.

Flexographic printing uses fast-drying inks, often paired with UV-curable or solvent-based formulations, which are resistant to moisture but depend heavily on the facestock and coating system.

Water-resistant labels may also incorporate a light varnish or overprint coating to reduce smearing.

While this adds protection, it does not prevent water ingress through cuts or edges. For this reason, print durability on water-resistant labels is limited to incidental contact with moisture. Continuous exposure or submersion will result in ink lift, blurring, or coating failure.

Waterproof labels are printed on polyester, polypropylene, vinyl, or polyethylene facestocks which do not absorb water and maintain dimensional stability during exposure to moisture, making them suitable for direct contact with wet or submerged environments.

Printing methods for waterproof labels include thermal transfer, UV inkjet, and laser. These technologies produce water-stable images without smear, fade, or lift under prolonged moisture. The durability comes from how the image binds to the facestock-either through heat fusion (as in laser and thermal transfer) or crosslinked curing (in UV systems).

Thermal transfer printing is most commonly used in waterproof labels. When combined with resin or wax-resin ribbons, thermal transfer printing resists water, cleaning agents, and abrasion. Resin ribbons, in particular, are engineered to bond with synthetic films and remain intact during exposure to high humidity, washdowns, or full immersion.

In UV inkjet printing, the ink is cured instantly using ultraviolet light, which forms a hard, solvent and water-resistant film on the label surface. This process prevents ink migration and ensures image stability even after long-term exposure to water or chemicals.

Laser printing uses a toner that is heat-fused into the facestock. On compatible synthetic materials, the result is water-resistant and suitable for industrial use where moisture exposure is expected.

When paired with waterproof adhesives and facestocks, these print systems produce labels that maintain legibility and image integrity during immersion, high-pressure cleaning, or exposure to harsh outdoor conditions. No protective overlaminate is required for water resistance, although one may be added to increase resistance to abrasion or solvents.

Water-resistant labels use coated paper and general-purpose adhesives. These materials are widely available, work with standard printing methods like inkjet and laser, and do not need lamination. As a result, they are low-cost and suitable for short-term or indoor use with light moisture exposure.

They are often applied to dry goods, cosmetic jars, and refrigerated items, where minor condensation does not affect performance. Their lower cost supports high-volume use without added material expense.

Waterproof labels cost 2 to 5 times more due to the use of synthetic facestocks like polyester, vinyl, or polypropylene. These block water and resist damage. Waterproof adhesives, such as solvent-based acrylics, are applied in thicker layers to maintain hold under exposure to water, heat, cold, and chemicals.

Waterproof labels often become more economical over time despite the higher upfront cost. A single durable label may replace multiple reapplications of a water-resistant one. This reduces labour, reprinting, and downtime.

Long-term reliability often outweighs initial logistics, asset tracking, and pharmaceutical costs.

Waterproof and water-resistant labels differ in how they respond to moisture, especially during prolonged or repeated exposure. This distinction is critical for choosing the correct label for your environment.

Water-resistant labels repel splashes, condensation, and light handling with wet hands. Coated paper surfaces allow droplets to be wiped away without damaging print or adhesion. These labels work well on refrigerated products or lotion bottles, where moisture is brief or incidental.

However, they are not designed for immersion. Once water penetrates through scratches or edges, the paper facestock absorbs moisture, which causes warping, smudging, and adhesive failure. Water-resistant labels degrade when placed in sinks, exposed to rain, or cleaned repeatedly.

Water-resistant labels are tested to IPX3, IPX4, or IEC IP44 standards, which confirm resistance to light splashes and spray. Avery Dennison uses IP44 for its products, making them suitable for refrigerated storage and mild washdowns.

Waterproof labels withstand complete and extended water contact. Made from non-absorbent synthetics like polypropylene or polyester, they maintain adhesion and print clarity during immersion. They resist swelling, detachment, and fading under wet conditions.

BS5609 Section 2 is the leading standard for waterproof performance. Labels must survive 90 days in saltwater while remaining legible and adhered. This standard applies to marine transport, chemical drums, and other high-moisture uses.

Waterproof labels are also tested for power-wash resistance, drying cycles, and salt spray. After drying, they return to their original condition without print loss or delamination.

This makes them suitable for reusable containers, industrial equipment, warehouse signage, and wet outdoor use.

A water-resistant label may be suitable for a jam jar or bathroom item. A waterproof label is necessary for anything submerged, pressure-washed, or left outdoors in rain.

Water-resistant labels, made from coated paper, offer limited protection against chemicals. They may repel light splashes or mild detergents, but are not built to handle alcohols, acids, oils, or solvents.

Exposure to isopropyl alcohol, diesel, or household cleaners can damage the coating, blur the print, or weaken the adhesive. Paper absorbs liquids, leading to swelling, staining, and delamination. Even wiping with disinfectant can erase print after a few uses.

Water-resistant labels are not rated for chemical durability beyond incidental contact.

Waterproof labels are made from polyester (PET), polypropylene (PP), or vinyl (PVC), which are chemically stable synthetics. These materials do not absorb liquids and resist a wide range of chemicals. Polyester withstands acids, bases, oils, fuels, and alcohols. Vinyl offers broad resistance but may degrade with strong solvents like acetone.

Polypropylene resists common fluids but is sensitive to certain solvents.

Adhesive and print methods also affect chemical resistance. Waterproof labels use high-grade acrylic adhesives that resist breakdown from oils, fuels, and cleaners. Combined with resin thermal transfer ribbons or UV-cured inks, they remain legible after chemical exposure.

Labels are tested to BS5609 Section 3 or ASTM D543 for resistance to substances like brake fluid, engine oil, sodium hydroxide, and isopropyl alcohol. Passing these tests confirms that labels stay attached and readable under chemical stress.

A label’s resistance to heat and cold depends on its facestock and adhesive.

Water-resistant labels use coated paper facestocks. These work well in ambient or refrigerated conditions. They are applied above 5 °C and retain adhesion down to -20 °C if applied to a dry surface and allowed to cure. This makes them suitable for kitchens, packaging lines, and standard refrigerated storage.

Problems occur in harsher settings. At low temperatures, paper can crack. Adhesives stiffen, preventing proper bonding. Freeze-thaw cycles weaken adhesion. Ice under or around the label can lift or damage the facestock. If moisture enters during thawing, the label may peel or delaminate.

High temperatures also reduce stability. Paper may yellow or char above 80 °C. Rubber adhesives start to soften or fail between 50 °C and 80 °C. Extended heat degrades coatings, blurs print, and causes adhesives to bleed. These labels are not suitable for ovens, heated machinery, or direct sun exposure.

Waterproof labels resist both cold and heat. They use synthetic facestocks like polyester, polypropylene, vinyl, or polyimide. These materials do not absorb moisture and maintain shape at extreme temperatures. Polyester works from -40 °C to +150 °C. Cryogenic-grade synthetics function at -80 °C or lower.

Brady’s B-473 polyester label withstood 30 days at -40°F and only minor change after five minutes at 210 °C. It also passed a 30-day xenon-arc test (ASTM G155 Cycle 1) with no visible damage. Epson’s industrial vinyl tape held print and adhesion after 390 hours of UV exposure at 63 °C and 50% humidity.

Each material has specific heat limits. Vinyl remains flexible in the cold but is not used above 90 °C. Polypropylene softens around 100 °C and is best kept below 80 °C for long periods. Polyimide, including aerospace and electronics, is used in extreme heat above 300 °C.

Temperature cycling adds mechanical stress. Paper labels on metal or plastic may lift or crack due to different expansion rates. Synthetic facestocks like polyester maintain stability and use adhesives that flex with temperature shifts.

Water-resistant labels use coated paper, which has low resistance to UV light. Paper contains lignin that breaks down under UV exposure, causing yellowing, fading, and weakening. Outdoors, these labels may degrade within weeks. Even with UV-stable inks, the paper itself remains vulnerable.

Some water-resistant options include UV-curable varnishes, which offer short-term protection under indoor lighting or limited sun exposure. These coatings delay fading but do not prevent long-term damage. Since the base is still paper, the label cannot withstand prolonged UV exposure. Water-resistant labels are best suited for indoor or short-term use.

Waterproof labels use UV-stable synthetic materials like polyester, polypropylene, and vinyl. Polyester strongly resists UV damage, especially in white or pigmented forms. It holds shape and colour after prolonged sun exposure. Vinyl is UV-resistant when stabilised and can retain clarity and flexibility for up to 10 years outdoors.

Polypropylene has moderate UV resistance and can become brittle unless enhanced with stabilisers. Modern polypropylene formulations with UV-blocking additives and protective laminates improve performance in outdoor use.

Many waterproof labels include UV-blocking overlaminates to protect both facestock and print. These transparent films absorb radiation and preserve the label surface. Depending on conditions, a vinyl label with a polyester laminate may remain intact for 5 to 10 years.

The printing method also affects fade resistance. Waterproof labels are typically printed using thermal transfer with carbon black resin ribbons, laser systems with fused toner, or UV-cured inks. These processes create images that resist smearing, bleaching, and fading under UV light.

Brady’s B-473 polyester label showed no damage after 30 days in a xenon-arc weatherometer (ASTM G155 Cycle 1). Epson’s industrial vinyl tape retained adhesion and clarity after 390 hours of UV exposure at 63 °C and 50% humidity. These results confirm long-term stability.

Even synthetic labels, especially vinyl, may show slight yellowing or chalking over time. However, polyester and polyimide maintain appearance longer than any paper-based material. Only synthetic waterproof labels offer the durability required for outdoor signage, solar panels, marine equipment, or electrical panels.

Label performance is defined not just by the materials used, but by how those materials behave under specific stress conditions. These include exposure to water, abrasion, chemicals, temperature cycling, and UV radiation. To assess durability, manufacturers and regulatory bodies rely on standardised test methods that classify labels by function, not appearance.

Understanding these classifications is essential for selecting a label that matches the environmental demands of your application.

Water-resistant labels are tested to entry-level ingress and material integrity standards. Ratings such as IPX3, IPX4, and IEC IP44 indicate resistance to light splashes and low-pressure water spray from any direction. These grades suit indoor packaging, retail environments, and short-term refrigeration, where moisture is incidental and exposure is time-limited.

Material-specific standards-such as TAPPI T441 (wet tensile strength for paper) and BS EN 20445 (paper performance under humid conditions)-are also applied to coated paper labels. These grades confirm the facestock can maintain structural integrity under damp handling but offer no assurance under immersion or chemical contact.

Waterproof labels, by contrast, are subject to far more stringent test conditions. The benchmark standard is BS 5609, particularly Section 2 (facestock and adhesive) and Section 3 (print system). BS 5609 requires labels to survive 90 days of saltwater immersion, followed by abrasion resistance tests using sand and synthetic rope under pressure.

Under IMDG regulations, labels that pass both sections are certified for use on hazardous chemical drums transported by sea. This is not a marketing claim; it is a marine compliance requirement.

Additional durability is assessed using ASTM D1000, which measures peel adhesion, shear strength, and holding power after water and solvent exposure. Labels used in industrial or electrical environments may also be tested under UL 969, which evaluates print legibility and adhesive performance after humidity, heat, and chemical exposure cycles.

Some manufacturers apply ASTM D543 to verify chemical resistance, exposing label samples to acids, bases, fuels, and cleaning agents over time. Others use weathering protocols like ASTM G155 (xenon arc exposure) to simulate long-term outdoor UV degradation.

Grades are not always printed on label packaging, but suppliers can provide technical datasheets confirming which tests have been passed.

In regulated sectors like chemical distribution, medical device labelling, and marine transport, selecting the correct grade is not optional. It is a requirement for safety, compliance, and operational reliability. In summary, label grades reflect more than material choice.

They represent tested performance against clearly defined conditions. Selecting the right grade ensures your labels remain in place, legible, and compliant-whether exposed to light spray or 90 days at sea.

In addition to formal certifications, some manufacturers perform internal tests to assess real-world durability. One example is the CS-10 abrasion test (Federal Standard 191A, Method 5306), which measures how many cycles a label can endure under abrasion before showing wear. LabelTac vinyl passed this test with 250 cycles at 500 grams without losing legibility.

Another example includes coin and eraser rub tests, which simulate repeated contact wear. Epson’s vinyl labels withstood 50 cycles of 500 gram-force coin rubbing and 50 cycles of 2 kilogram-force eraser rubbing without visible print damage.

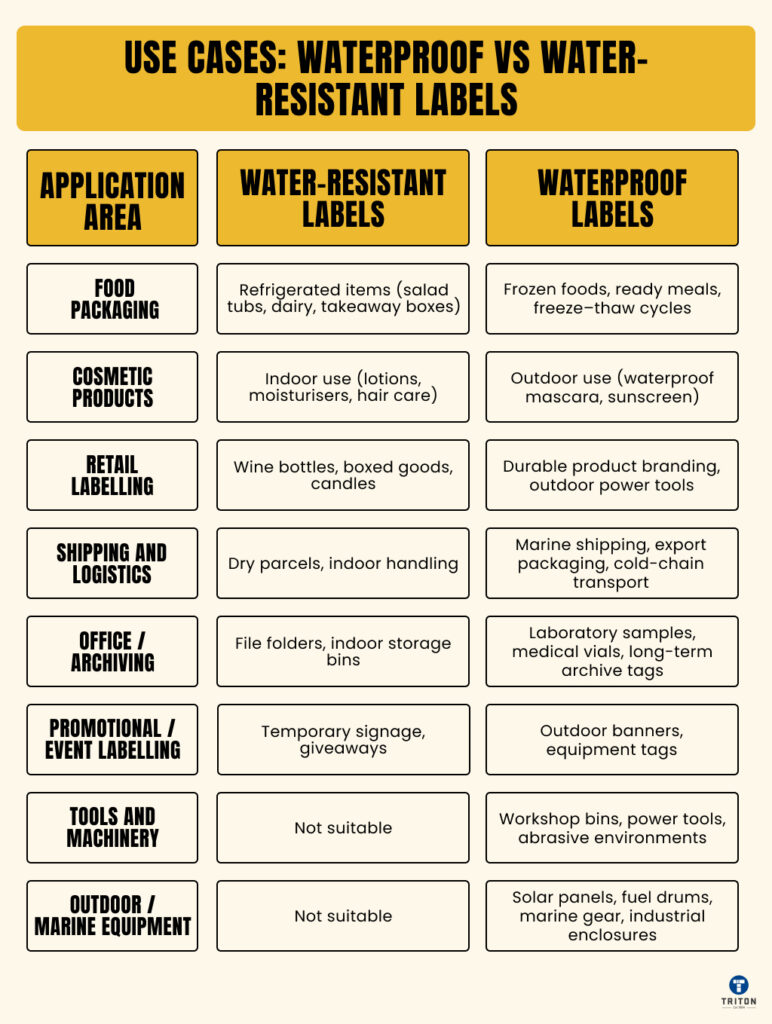

Choosing the right label type depends on how and where it will be used. Below are some uses of water-resistant versus waterproof labels.

Water-resistant labels are suitable for indoor or low-moisture settings where the label may occasionally come into contact with water but will not be submerged or heavily handled.

Waterproof labels are used in environments that involve water immersion, chemical exposure, rough handling, or long-term outdoor use. These labels are designed to stay intact and readable for years.

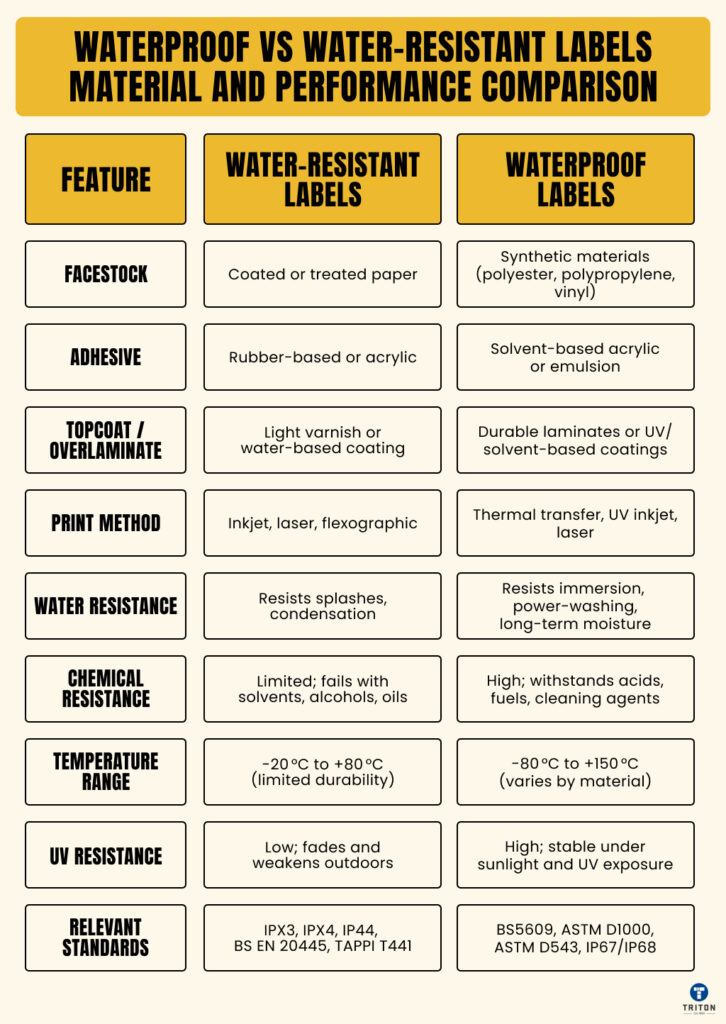

Feature | Water-Resistant Labels | Waterproof Labels |

|---|---|---|

Facestock | Coated or treated paper | Synthetic materials (polyester, polypropylene, vinyl) |

Adhesive | Rubber-based or acrylic | Solvent-based acrylic or emulsion |

Topcoat / Overlaminate | Light varnish or water-based coating | Durable laminates or UV/solvent-based coatings |

Print Method | Inkjet, laser, flexographic | Thermal transfer, UV inkjet, laser |

Water Resistance | Resists splashes, condensation | Resists immersion, power-washing, long-term moisture |

Chemical Resistance | Limited; fails with solvents, alcohols, oils | High; withstands acids, fuels, cleaning agents |

Temperature Range | -20 °C to +80 °C (limited durability) | -80 °C to +150 °C (varies by material) |

UV Resistance | Low; fades and weakens outdoors | High; stable under sunlight and UV exposure |

Relevant Standards

| IPX3, IPX4, IP44, BS EN 20445, TAPPI T441 | BS5609, ASTM D1000, ASTM D543, IP67/IP68 |

The decision depends on how much moisture, handling, and environmental stress the label will encounter.

Water-resistant labels are suitable for indoor, short-term, or light-duty use. If your labels will face only light splashes, condensation, or occasional damp handling, these are a cost-effective option. They are commonly used on refrigerated products, retail packaging, shipping labels, or office files.

They offer enough durability in dry, controlled settings without the added material cost of more rugged constructions.

Waterproof labels are required in demanding environments. These labels are built for long-term exposure to water, chemicals, abrasion, or outdoor conditions.

They are ideal for manufacturing, marine transport, laboratories, freezers, or equipment that sees frequent contact. If your application requires compliance with standards such as BS5609, ASTM D1000, or IP67, waterproof labels are necessary to meet those performance expectations.

Selecting the right label depends on how much moisture, abrasion, and environmental exposure your application involves. Water-resistant labels suit dry or short-term use, while waterproof labels offer long-lasting performance in harsh conditions.

Explore the Triton Store to resolve your labelling and printer concerns. Connect with us through the widget below.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below