Imagine a container arriving at the distribution centre after days in transit. The warehouse team moves to scan the shipping label, but the barcode is torn or scuffed and unreadable. Perhaps moisture has faded the print.

In this scenario, data must be entered manually which delays receiving operations and increases the chance of errors. This familiar scenario usually originates from a simple oversight – the wrong label material.

Polypropylene (PP) and Vinyl (PVC) are frequently specified for such tasks. However, their resistance to abrasion, moisture, and tearing differs significantly.

This analysis directly compares PP and Vinyl sticker materials. We examine their physical properties, print compatibility, and performance under stress, helping you choose the correct label so that your data survives its journey every time.

Polypropylene (PP) and Polyvinyl Chloride (PVC) labels perform differently because their basic chemical makeup varies.

PP is a thermoplastic with a propylene monomer chain. This low-density, lightweight semi-crystalline chain provides good resistance to moisture and many chemicals and natural flexibility.

PVC, however, incorporates chlorine atoms into its polymer backbone. This results in a denser, more rigid material with good tensile strength and natural resistance to weathering and UV light. Because PVC is stiff, additives called plasticisers (e.g., phthalates) are mixed to make it flexible for label use.

While effective, these plasticisers migrate over time, gradually moving from the PVC material to its surface or into adjacent materials. Migration happens because plasticisers are not chemically bonded to the PVC polymer chains but are physically mixed into the PVC matrix.

The molecular weight of the plasticiser, the compatibility between the plasticiser and PVC, and environmental conditions like temperature and humidity influence this process.

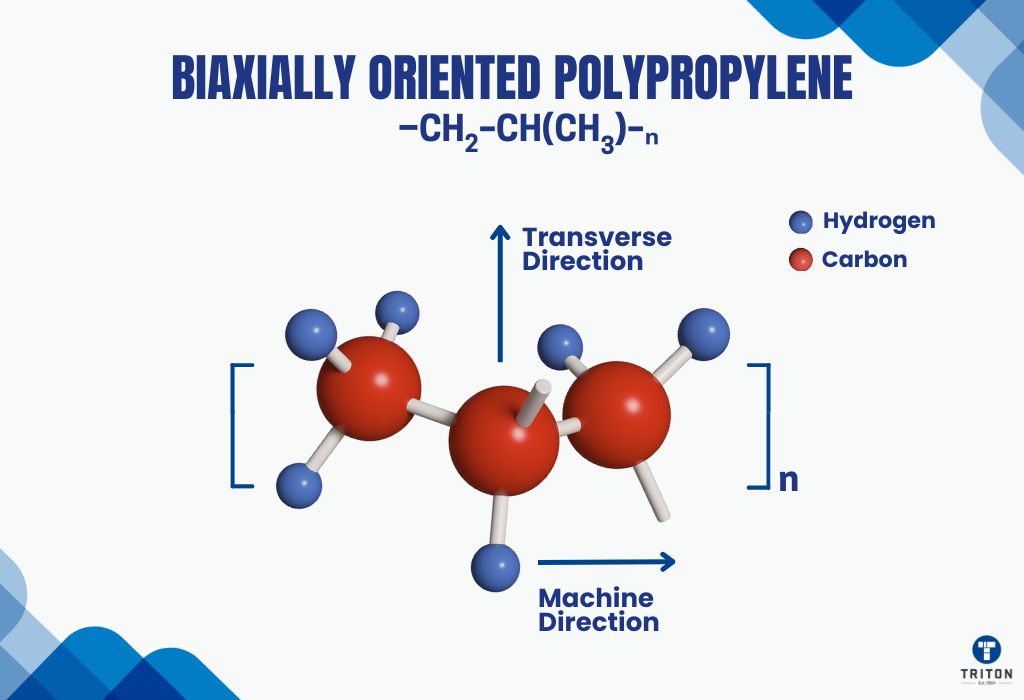

A common variant, Biaxially Oriented Polypropylene (BOPP), is produced by stretching the PP film lengthwise and widthwise. Stretching aligns the polymer chains and increases the film’s strength, tear resistance, and clarity, which makes BOPP suitable for high-quality printing and rugged use.

Selecting the right material is only half the game; ensuring your print stays put and remains readable, especially barcodes, depends on matching the printing method to the chosen film – polypropylene (PP) or Vinyl (PVC). Both materials are non-porous surfaces that require special printing techniques.

Thermal transfer (TT) printing is a common and reliable method for both PP and Vinyl labels in logistics.

Basic wax ribbons, while economical, offer poor adhesion and smudge easily on these smooth films – unsuitable for most supply chain handling. Wax/resin hybrid ribbons require slightly higher heat but create crisp, durable prints, including sharp barcodes, that resist moderate abrasion on both PP and Vinyl.

Resin ribbons are the top choice for durability against heavy handling, chemicals, or outdoor exposure. They form strong bonds with PP and PVC and resist abrasion and solvents. Resin printing is durable on PVC because it resists interference with ink adhesion due to plasticiser migration.

Direct thermal (DT) printing, which uses heat-sensitive coated labels without a ribbon, offers simplicity at the cost of longevity. DT prints on PP and Vinyl typically last only 6-12 months indoors before fading, especially when exposed to UV light, heat, or rugged conditions.

Inkjet and laser printing on standard PP or Vinyl films require special topcoats to ensure ink or toner adheres properly. These coatings add cost and complexity. Laser printing also requires careful management of fuser heat to avoid distorting the label material, particularly the less heat-tolerant PVC.

For high-volume, durable labelling, thermal transfer printing with the correctly matched wax/resin or resin ribbon usually provides the most reliable and cost-effective result for both PP and Vinyl.

The molecular nature of PP and Vinyl surfaces dictates adhesive choice.

PP, a non-polar polyolefin, presents a low surface energy (LSE) that inherently resists wetting and bonding by many standard adhesives. This requires adhesives formulated to overcome this low affinity.

Conversely, PVC’s structure includes polar chlorine atoms, resulting in a higher surface energy (HSE) that is generally more receptive to adhesive bonding; however, the presence of plasticisers in PVC can leach to the surface and interfere with or degrade the adhesive interface over time.

Polypropylene Labels: To bond with PP’s LSE surface, adhesives must promote better surface contact and intermolecular force development. Options include:

PVC Labels: While PVC’s HSE aids initial adhesion, long-term performance hinges on managing plasticiser effects:

For logistics, the adhesive’s chemical compatibility with the label face stock, the substrate (corrugated, plastic totes), and its ability to maintain bond strength through temperature cycles and potential chemical exposures are also important for preventing label failure.

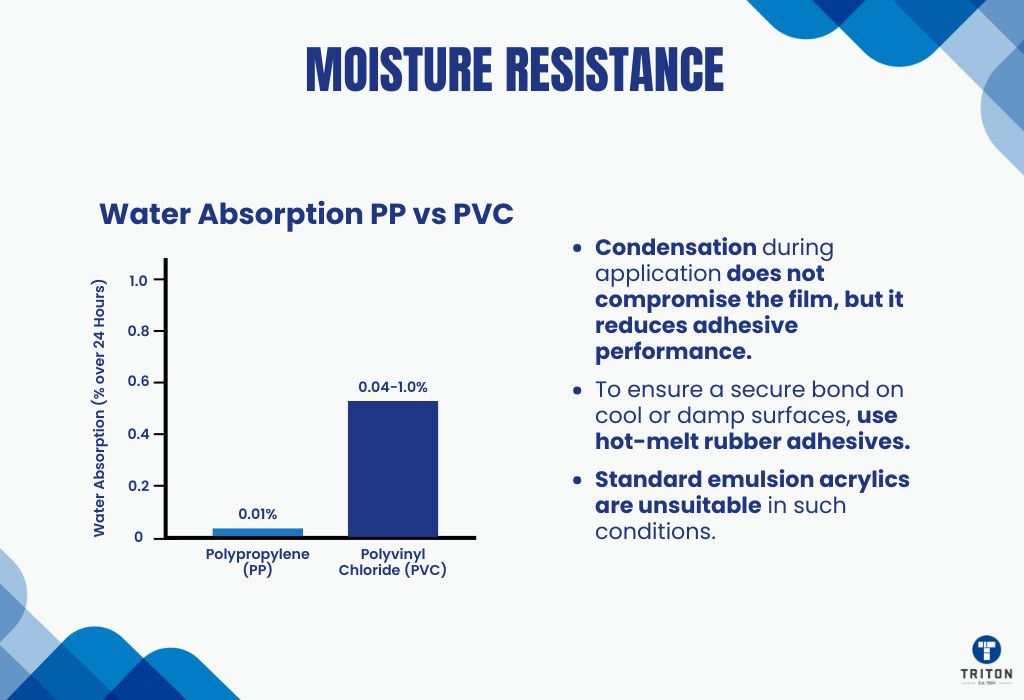

Both PP and PVC films maintain their structural integrity under water exposure. Polypropylene films have 0.01% absorption over 24 hours. Vinyl (PVC) film water absorption measures between 0.04% and 1.00%.

The main challenge in scenarios where condensation forms during application is not film failure, but reduced adhesive performance. In such conditions, success depends less on the film’s water resistance and more on using adhesives – such as hot-melt rubber types – designed to bond to cool or damp surfaces, unlike standard emulsion acrylics.

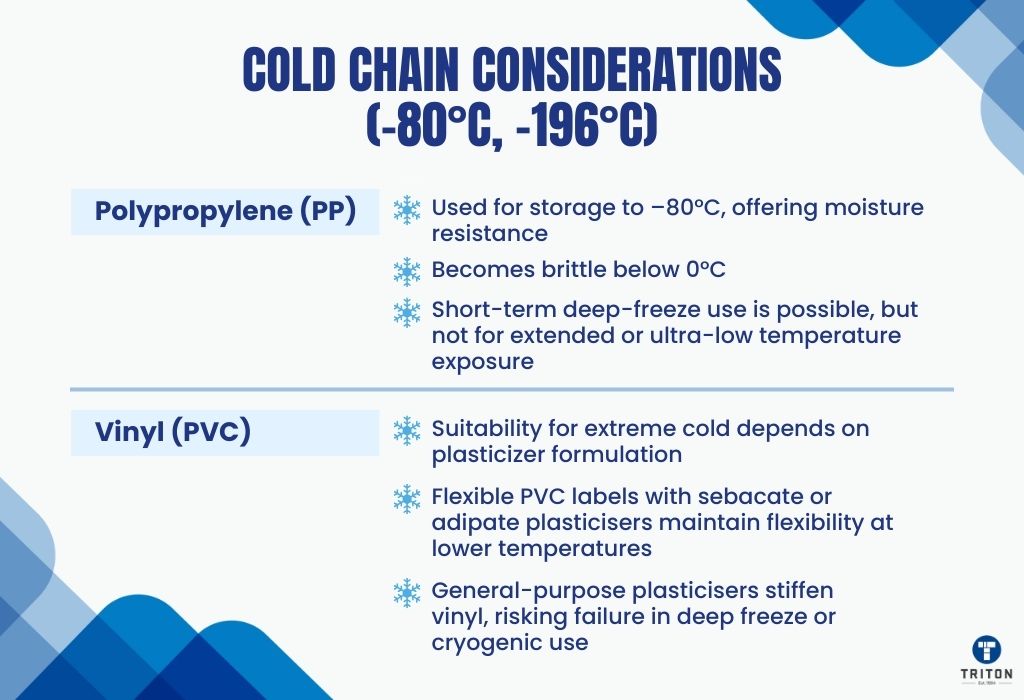

Labels in deep-freeze (-80°C) or cryogenic (-196°C) conditions must resist peeling, cracking, and print degradation during exposure to ultra-low temperatures and potential freeze-thaw cycles.

Standard label constructions typically fail.

Polypropylene is sometimes used for storage down to -80°C, offering moisture resistance. However, PP becomes brittle below 0°C, compromising its reliability for long-duration deep-freeze applications or any cryogenic use.

Vinyl’s suitability for extreme cold depends on its specific plasticiser formulation. For instance, flexible PVC labels using adipate plasticisers (like dioctyl adipate, DOA) or sebacate plasticisers (like dioctyl sebacate, DOS) maintain better flexibility at lower temperatures compared to those with common phthalates such as DEHP (di-2-ethylhexyl phthalate).

General-purpose plasticisers significantly cause the vinyl to stiffen, risking label failure in deep-freeze conditions, let alone at -196°C.

Therefore, any intended use of PVC-based labels at cryogenic temperatures demands rigorous validation of the complete label construction. This validation must include testing for:

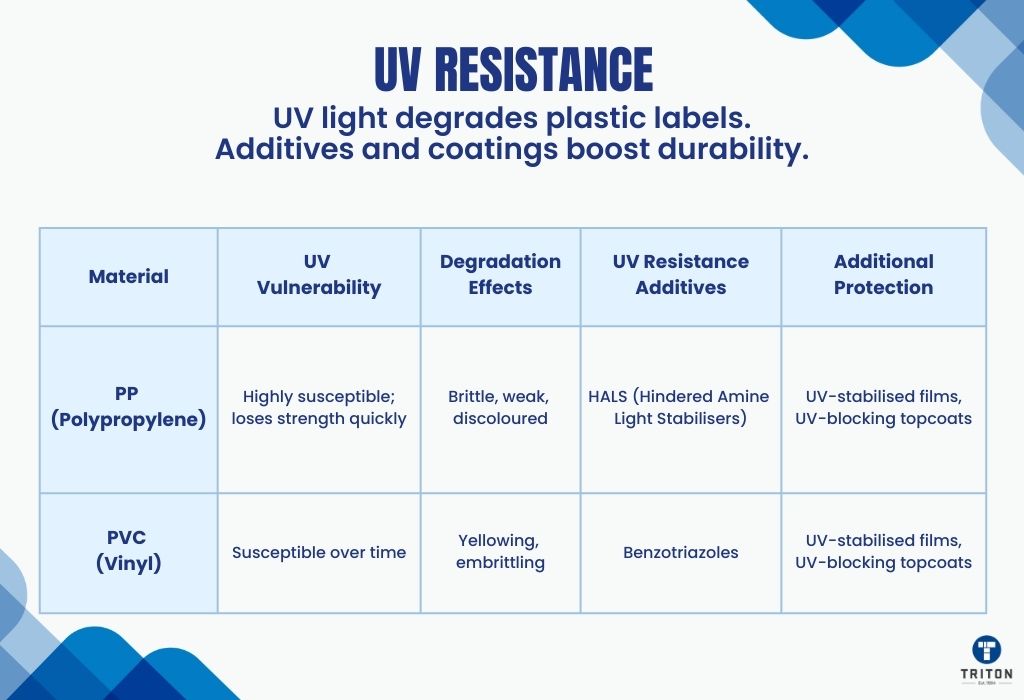

Sunlight’s UV radiation breaks the chemical bonds in plastic labels, causing discolouration, brittleness, and print fade.

Unmodified Polypropylene (PP) is highly susceptible to UV and rapidly loses strength. Standard Vinyl (PVC) also degrades, typically yellowing and embrittling.

UV resistance depends on using the right additives for both PP and PVC. PP often uses HALS, while PVC includes benzotriazoles. UV-stabilised films and UV-blocking topcoats are also used in outdoor labels – this approach also protects the printing.

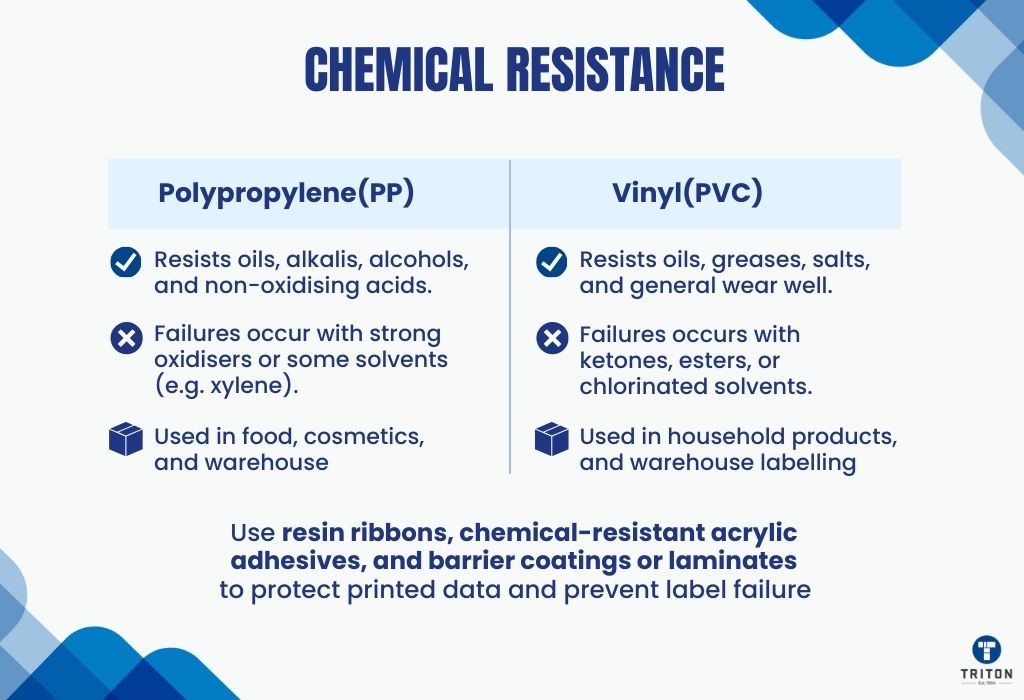

Polypropylene (PP) and Vinyl (PVC) resist many chemicals found in logistics, but their limits differ.

PP resists oils, alkalis, alcohols, and non-oxidising acids. It’s widely used in food, cosmetics, and warehouse environments where labels may come into contact with lubricants, creams, or sanitisers. Failures occur with strong oxidisers or some solvents (e.g. xylene).

PVC also handles oils, greases, salts, and general wear well, but degrades with ketones, esters, or chlorinated solvents. Plasticisers can affect chemical tolerance.

Use resin ribbons, chemical-resistant acrylic adhesives, and barrier coatings or laminates to protect printed data and prevent label failure. Where strong solvents or long-term chemical contact are expected, PP and PVC may not hold up. In such cases, switch to PET or polyimide labels.

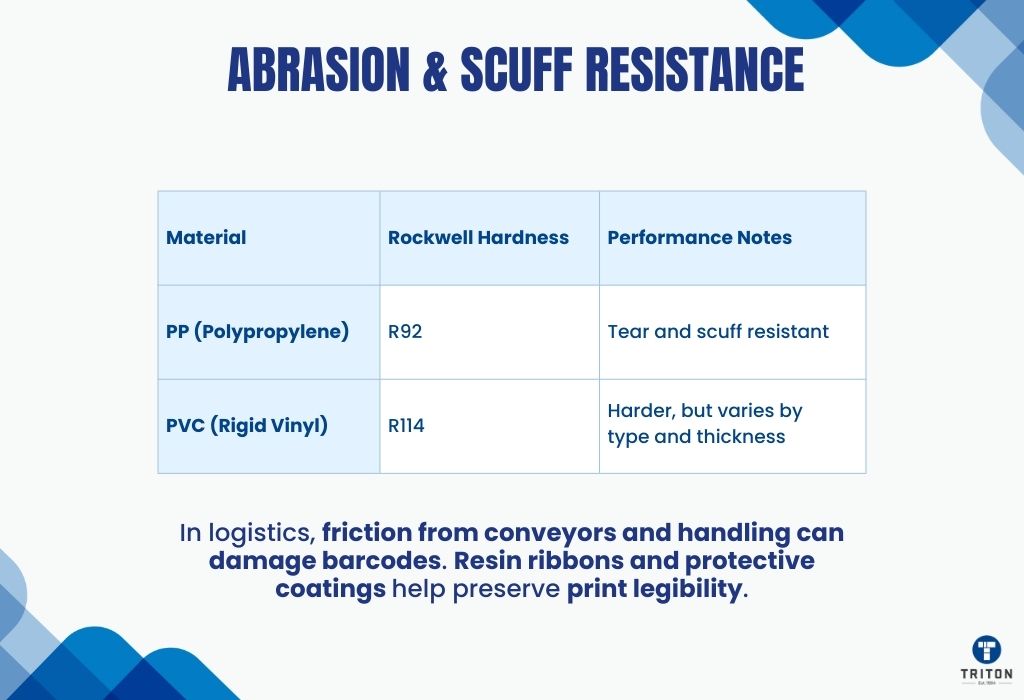

Polypropylene (PP) shows tear and scuff resistance (Rockwell R 92 hardness). Rigid Vinyl (PVC) typically has greater hardness (Rockwell R 114), though PVC performance varies significantly by formulation and thickness.

In logistics, labels encounter friction from conveyors, packaging, and general handling, which threatens the legibility of printed data, especially barcodes.

Resin thermal transfer ribbons are used to ensure print survival through these conditions. For high-wear scenarios, protective overlaminates or specialised topcoats are applied.

Performance Factor | Polypropylene (PP) | Polyvinyl Chloride (PVC) | Key Considerations & Enhancements |

|---|---|---|---|

Moisture/Humidity Resistance | Excellent inherent resistance; low water absorption. Good for damp conditions. | Excellent inherent resistance; non-porous. Good barrier properties. | Both excellent. Performance in condensation/freeze-thaw depends heavily on adhesive choice (e.g., hot melt for damp) and potential use of coatings/laminates. |

Abrasion/Scuff Resistance | Good toughness and scuff resistance; moderate abrasion protection. Easier to tear than PET. | Good durability; potentially higher hardness (rigid PVC) and tear/abrasion resistance (thicker grades). | PVC may have an edge in hardness/heavy wear. System approach critical: use resin ribbons , protective laminates/topcoats for demanding applications.9 Test specific grades. |

UV/Sunlight Exposure Resistance | Standard PP is highly vulnerable; degrades quickly becoming brittle. BOPP is often UV resistant. | Standard PVC degrades (discoloration, brittleness) but potentially slower than PP. Better baseline longevity? | Conflicting data on inherent resistance. Additives are key. Use UV-stabilized PP (BOPP UV) or UV-stabilized PVC/Vinyl with UV-blocking coatings/laminates for outdoor use. Verify specs. |

Temperature Cycle Performance | Becomes brittle below 0°C. Broad service range (-40°C to +80/100°C). Good stability. | Tolerates extremes well; broad service range (-40°C to +80°C typical). Plasticizer stability/shrinkage potential. | Adhesive selection (MAT, service range, cycle resistance) is paramount. PP brittleness is a risk if handled cold. Consider substrate interaction. PET is often superior. |

Chemical Resistance

| Excellent vs. oils, fats, acids, bases, many solvents. Weak vs. strong oxidizers, some hot solvents. | Good vs. oils, greases. Weak vs. ketones, chlorinated solvents. | Consult specific chemical compatibility charts. Use protective coatings/laminates and resistant inks/adhesives. Consider PET/PI for harsh chemicals. |

Labels fail when material limits are ignored. Polypropylene works well in dry, fast-moving environments where speed and volume matter more than long-term exposure. Vinyl offers better resilience under UV, abrasion, and extreme cold, but requires careful adhesive handling and print durability.

If the label must survive water, chemicals, sunlight, or rough handling, match the face stock and the adhesive and print method to the task. Test the complete label construction under real conditions, because failure starts at the surface in logistics. For access to reliable, logistics-ready labelling materials and printing solutions that match these demands, explore the options available at the Triton Store.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below