In the intricate ecosystem of supply chain management, the role of warehouse labels is paramount. A warehouse label, far from being mere stickers or tags, is the foundational pillar that guarantees seamless inventory flow, precise order fulfilment, and overall efficiency of warehouse operations.

With the varied demands of warehousing and technological advancements, there’s a wide range of label types, each designed for specific functions and settings.

This article delves into the various types of warehouse labels, elucidating their features, applications, and the technological advancements that underpin them. So, let’s get started.

To optimise warehouse operations, it’s imperative to understand the diverse range of label options available. The most common types of warehouse labels are as follows:

Let’s discuss these types of labels in detail.

Warehouse rack beam labels (also called warehouse rack labels) are adhesive identifiers placed on warehouse racking beams. These labels commonly utilise 1D or 2D dimensional barcodes, numbers, and letters, aiding in inventory location, product identification and management.

Check out our article on types of barcodes to learn about different barcoding technology available today.

Warehouse rack labels are typically made from materials such as polyester or polypropylene. They are laminated to withstand the wear and tear of a warehouse environment. These rack labels also come as magnetic labels for warehouses that undergo frequent reconfigurations.

Different warehouses have different needs. As a result, there are special labels for different situations.

For example, some rack labels can stick and be read easily, even in super cold places, like inside a big freezer. Similarly, there are rack labels with a retro-reflective surface, allowing for easy scanning from a distance.

Warehouse rack upright labels (or totem labels) are adhesive markers strategically positioned on the vertical supports of the warehouse management system. These labels are integral to the precise warehouse organisation and management of inventory.

A distinguishing feature of these rack labels is their vertical arrangement, showcasing a series of barcodes that encapsulate specific information for each level of racking within a bay in a particular aisle. To enhance clarity and reduce potential confusion during the scanning process, these labels are often colour-coded by level.

Here are some examples of how a warehouse might use colour-coded labels:

Vertical location labels are an excellent solution for multilevel warehouse racks. They eliminate the need for long-range barcode scanning and minimise potential confusion and scan errors. Depending on the warehouse’s requirements, the adhesiveness of labels can be either permanent, adhering firmly to the uprights, or temporary (removable labels), allowing for adjustments as the inventory or structural needs evolve.

In essence, warehouse rack upright labels, with their vertical label design and colour-coded system, offer a streamlined approach to inventory management, ensuring that items are easily locatable and that inventory processes run smoothly.

Warehouse pallet labels, often called LPN labels or licence plate numbers, are adhesive markers specifically designed to track movable units within a warehouse environment. These units can range from pallets and cartons to plastic bins, each requiring precise identification for efficient inventory management.

Typically, LPN labels are manufactured using paper stock and come preprinted on rolls with a sequential barcode system. This system facilitates the tracking of movable units from the moment they enter the warehouse until their departure.

The adhesive properties of label pallets are versatile, catering to various warehouse applications and temperature conditions. There are various types of pallet labels available based on different use cases, such as corner-wrap pallet labels.

In summary, warehouse pallet labels, with their unique barcode system and customisable features, are indispensable in ensuring the smooth flow of inventory, facilitating quick item retrieval and data entry, and enhancing overall warehouse efficiency.

Tote/bin labels are specifically designed for plastic storage bins or other containers commonly used to store individual items. Correctly identifying these bins with barcode labels ensures that workers can quickly locate articles, fulfil orders, and manage product inventory precisely.

Warehouse tote and bin labels are frequently circulated and require proper identification.

In essence, warehouse tote and bin labels are crucial in ensuring a seamless flow of operations, enhancing efficiency, and minimising errors in the warehousing domain.

In warehouses, the floor isn’t just for storing things and walking but also for showing important information. Warehouse floor labels serve this very purpose and come in adhesive floor labels and screw-down form.

Floor labels serve multiple purposes: they divide spaces, highlight potential hazards, outline specific workstations and bulk storage locations, and even direct traffic. More than just markers, they convey crucial safety information, acting as visual cues that guide employees seamlessly through the facility.

By providing clear boundaries and directions, floor labels reduce the chances of errors, misplacements, and accidents by warehouse employees. They ensure that every movement, whether of goods or personnel, is systematic and efficient.

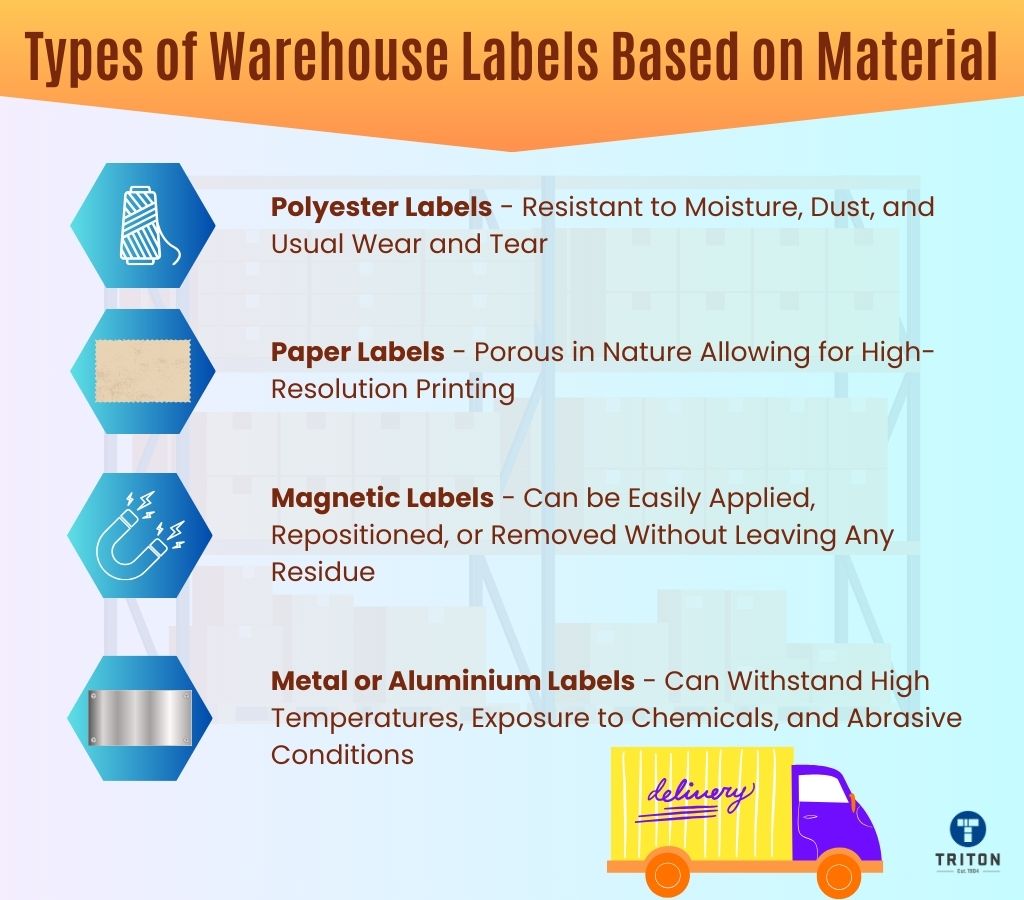

Warehouse labels are also categorised based on materials. These are as follows:

Polyester warehouse labels are renowned for their ability to withstand many environmental challenges. Their resistance to moisture, dust, and the usual wear and tear ensures they remain legible and intact, even in the most demanding warehouse environments.

One of the standout characteristics of polyester labels is their capacity for high-quality imaging. The smooth surface of polyester allows for the sharp and precise printing of barcodes, QR codes, and alphanumeric identifiers. This clarity ensures easy scanning and reduces the likelihood of errors, a critical feature in the fast-paced warehousing world.

Did you know barcodes and QR codes are two different technologies often confused with each other? Our article on QR code VS barcode will help you understand the difference.

Moreover, polyester labels are adept at handling a wide range of temperatures. Whether placed in the sweltering heat of a manufacturing unit or the chilly confines of a refrigerated storage section, polyester labels consistently retain their adhesive qualities and legibility.

As one of the earliest materials used for labelling, paper has been a staple in various industries, including warehousing. While they might seem simple, paper labels offer a cost-effective and versatile solution for multiple applications.

Paper labels are often chosen for their ease of use and adaptability. These labels can be quickly produced in large quantities, making them ideal for businesses that require rapid and frequent labelling changes. Their porous nature allows for high-resolution printing, ensuring that barcodes like UPC, EAN, MaxiCode barcodes, Codablock barcodes, QR codes, and alphanumeric identifiers are clear and easily readable. This clarity is essential in warehouse settings where quick scanning and accurate data retrieval are paramount.

However, it’s also worth noting that paper labels have certain limitations. They are susceptible to environmental factors such as moisture, excessive heat, and chemicals. Such environmental factors degrade paper labels quickly, affecting their legibility and adhesive properties. This makes paper labels less suitable for warehouses with extreme conditions or where long-term durability is a primary concern.

Yet, the affordability of paper labels cannot be overlooked. The paper offers a cost-effective solution for businesses operating on tight budgets or those that don’t require long-lasting labels. They are handy for temporary applications, such as short-term storage or one-off events.

Magnetic labels, with their unique properties and features, have emerged as a go-to solution for warehouses that prioritise flexibility and ease of reconfiguration. Magnetic labels offer a blend of durability and reusability that caters to the dynamic nature of modern warehousing.

Magnetic labels adhere securely to metal surfaces, such as racking systems, without adhesive. This inherent magnetic property ensures they can be easily applied, repositioned, or removed without leaving any residue, making them ideal for warehouses undergoing frequent layout changes or inventory reorganisations. Their ease of relocation reduces the time and resources spent on creating and applying new labels, leading to significant cost savings in the long run.

Beyond their flexibility, magnetic labels are known for their durability. These are resistant to moisture, dust, and many chemicals, ensuring they remain legible and intact even in challenging warehouse environments.

Moreover, their robust nature also means that they can withstand the regular wear and tear of warehouse operations, from the movement of goods to the hustle and bustle of machinery and personnel.

Designed for environments that require resilience against extreme conditions, metal/aluminium labels offer a combination of strength, longevity, and elegance.

Metal and aluminium labels are inherently robust, making them resistant to various challenges that might compromise other labelling materials. Their ability to withstand high temperatures, exposure to chemicals, and abrasive conditions ensures they remain intact and legible even in the harshest environments. This makes them particularly suitable for warehouses or industries where conditions might be extreme, such as those dealing with heavy machinery, chemical processing, or outdoor storage.

Unlike adhesive-based labels, which might peel off or degrade over time, metal labels can be affixed using rivets or screws, ensuring they remain in place for years, if not decades. This long-lasting nature translates to cost savings in the long run, as the need for frequent replacements is significantly reduced.

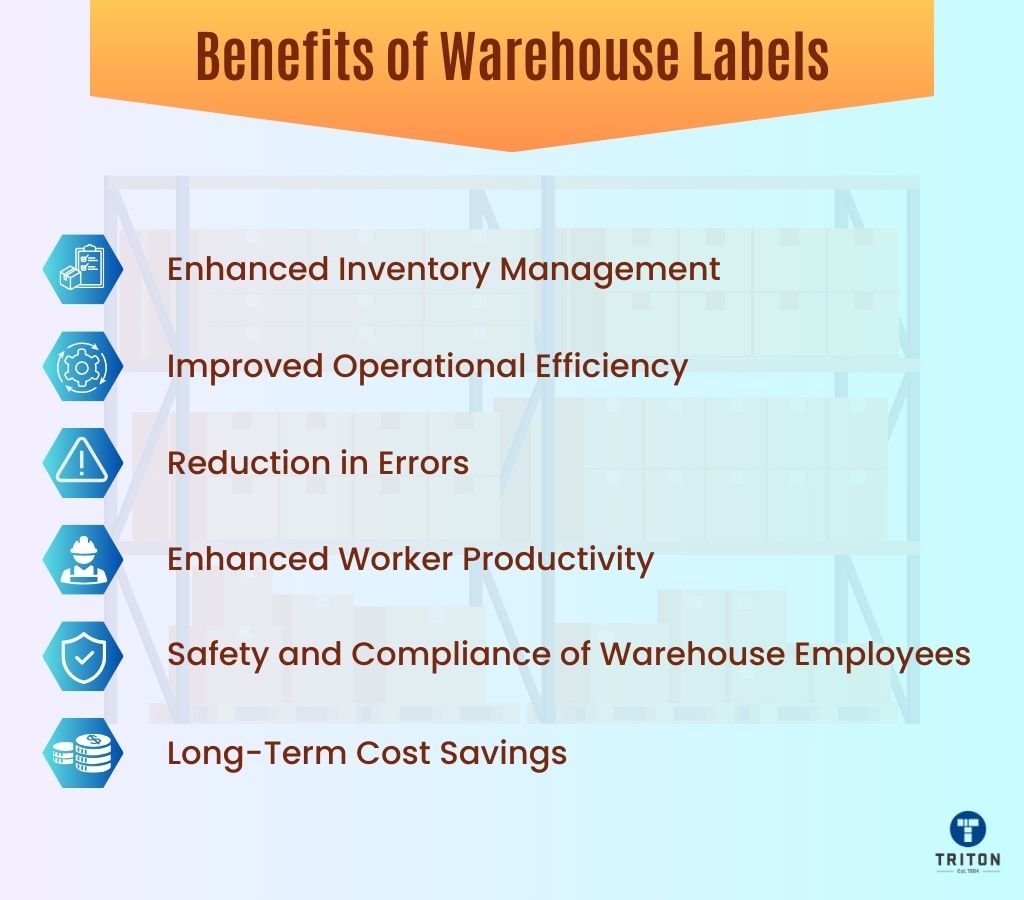

Warehouse labels, while seemingly simple, play a pivotal role in the efficient functioning of a warehouse. Their importance extends beyond mere identification, offering benefits that streamline operations, enhance accuracy, and boost productivity.

Here’s a deeper dive into the numerous advantages of employing warehouse labels:

Proper labelling ensures that every item or pallet has a designated place. This systematic organisation facilitates quicker item retrieval, reduces misplacements, and ensures accurate tracking.

With a well-labelled system, stocktaking becomes a more streamlined process, reducing the chances of discrepancies.

Time is of the essence in warehousing. Labels, especially those with barcodes or QR codes, expedite the process of locating and scanning items. This speeds up various operations, from receiving and shelving new stock to picking and dispatching orders. The result is a smoother workflow and quicker turnaround times.

Mistakes in warehousing are costly. Misplaced items, wrong shipments, or inventory mismatches can lead to financial losses and dissatisfied customers.

Proper labelling acts as a guard against such errors, ensuring that items are correctly stored, picked, and dispatched.

A well-labelled warehouse is a boon for the workforce. Employees don’t have to waste time searching for items or second-guessing storage locations. This boosts their productivity and reduces frustration, leading to a more motivated and efficient team.

Labels aren’t just for inventory. They play a crucial role in safety and compliance.

Labels often make use of hazard statements, hazard signs, signal words and other GHS label requirements, indicating hazardous materials, weight limits, or handling instructions to ensure that items are handled correctly, reducing the risk of accidents.

Moreover, in certain industries, proper labelling is a regulatory requirement, making it essential for compliance.

While there’s an initial investment in labelling, the long-term savings are significant.

Reduced errors mean fewer returns and compensations. Enhanced efficiency translates to quicker order fulfilment, potentially reducing storage times and associated costs.

Over time, these savings accumulate, offering a substantial return on investment.

In the world of warehousing, the right label makes all the difference. From durability to adaptability, each label type serves a unique purpose, ensuring seamless operations.

Here’s a guide on how to print different types of warehouse labels:

Thermal printers are highly recommended for generating warehouse labels due to their exceptional precision and cost-effectiveness. These printers don’t require ink or toner, leading to economical printing. Moreover, they demand minimal maintenance and boast user-friendly operation.

At Triton, we present an extensive array of thermal printers tailored to help you print warehouse labels of top-notch quality swiftly and affordably. Our selection comprises a variety of thermal printers from renowned brands like Zebra, Honeywell, and TSC, alongside coloured label printers from OKI. Our diverse collection of accurate, efficient, and resilient printers covers desktop label printers, industrial label printers, direct thermal printers, thermal transfer printers and barcode label printers.

To ensure seamless printing, we also offer an assortment of print consumables, encompassing thermal labels, thermal carton labels, thermal carcase tags, thermal inserts, and thermal transfer ribbons.

Contact us today via the live chat widget, and discover why Triton is the right choice for all your thermal printing needs.

Designing effective warehouse labels is crucial for ensuring efficient operations, accurate inventory management, and reducing errors. Here are some generic tips for designing different types of warehouse labels:

Creating warehouse labels manually can be a challenging task, requiring careful consideration of numerous factors. Thankfully, software can automate this intricate process, making label design more efficient.

One highly recommended solution is Seagull Scientific’s BarTender software. Renowned as a leading label design and printing software, BarTender boasts an intuitive interface and robust data management capabilities. By simplifying label design, this software enhances accuracy, ultimately boosting productivity and efficiency.

Triton is proud to be a trusted provider of Seagull Scientific’s BarTender Software. We recognise the uniqueness of each organisation’s needs and thus offer all four BarTender editions: Starter, Professional, Automation, and Enterprise. We also offer the latest addition to the BarTender family, BarTender Cloud – a cutting-edge cloud-based solution for on-the-go label printing and design management.

So why wait? Contact us now via the live chat widget, or fill out a form here and get started on experiencing the best software solutions for your business.

In conclusion, warehouse labelling is indispensable in streamlining operations, ensuring accuracy, and enhancing efficiency within storage environments.

From magnetic and cold storage labels to retro-reflective and floor labels, each type serves a unique purpose tailored to the diverse needs of modern warehouses.

Investing in the right labels simplifies inventory management and significantly boosts safety and productivity. As the backbone of effective warehouse management, choosing the appropriate label type is paramount for a seamless and efficient operational flow.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below