Void labels are tamper-evident tools that leave behind a visible message – usually “VOID” – when peeled off. This marks unauthorized access and deters theft, counterfeiting, and product tampering.

Used across sectors, they help secure goods from manufacture to point-of-sale. These labels are part of legal packaging requirements in regulated industries like pharmaceuticals.

This article explains how void labels work, where they are used, and why they are critical to supply chain integrity. It also compares common label types, outlines key buying considerations, and highlights trends in tamper-evident packaging so you can choose the right solution for your business.

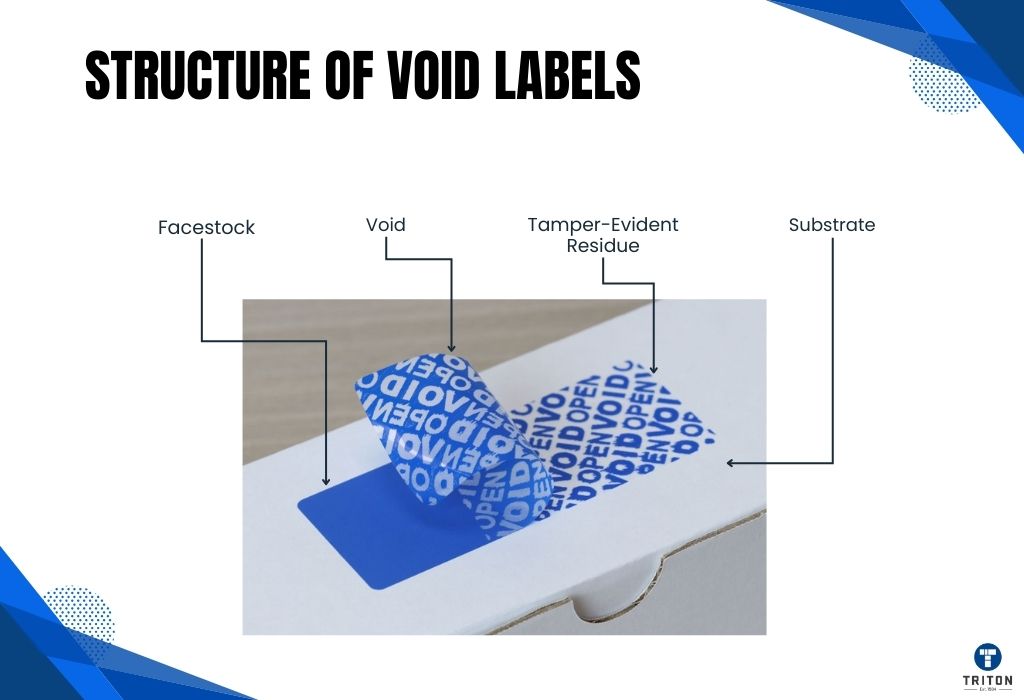

Void labels are made of three to five layers. These layers are designed to split when the label is peeled, showing clear signs of tampering.

The facestock is the printable surface, typically made of polyester or polypropylene. Polyester can withstand heat, UV, and solvents. Polypropylene is more flexible and suited to short-term applications.

Under the facestock is a PET carrier layer that supports the label’s structure and controls how the void pattern separates.

Beneath that sits the release layer (a.k.a. void message layer) that triggers the hidden message. It’s engineered to split when the label is peeled, exposing a void pattern on the product, the label, or both. The failure is irreversible.

The adhesive beneath the release layer determines how the label bonds. Most void labels use permanent acrylic adhesives. The adhesive must match the surface—metals, plastics, painted finishes – otherwise; the void effect won’t activate. Non-transfer and partial-transfer void labels use high-tack acrylic adhesives modified with tackifiers and functional resins to bond securely to low-energy plastics like polyethylene and polypropylene.

A release liner covers the adhesive before application. It’s made of silicone-coated paper or PET film. The liner must separate cleanly to prevent premature activation of the void message during handling or automated dispensing.

Optional features include serial numbers, QR codes, barcodes, or microtext for authentication. These are either printed on the facestock or embedded in the void pattern.

Layer | Function | Material | Notes |

|---|---|---|---|

Facestock | Displays printed information, branding, or serial data | Polyester (PET), Polypropylene (PP) | Chosen for durability, printability, and surface finish

|

PET Carrier | Adds strength, controls how the void layer separates during peeling | Clear or metalized PET film | Not always present – used in multi-layer or premium constructions.

Adds dimensional stability (avoids warping or curling) |

Void Pattern Layer | Reveals tamper message when split or lifted | Coated film with pre-engineered pattern | Message appears on label, surface, or both depending on label type |

Adhesive | Bonds the label to the product surface | Acrylic (standard or high-tack)

| May be modified to suit low-energy plastics or specific environmental needs |

Release Liner | Protects adhesive before use; enables automated dispensing | Silicone-coated paper or PET film | Removed during application; must peel cleanly to avoid premature voiding

|

The point at which the label fails, called the failure mode, determines how the void message is revealed and what is left behind.

There are three failure modes in void labels: adhesive failure, film delamination, and pattern release.

In adhesive failure, the label separates at the interface between the adhesive and the product surface. This usually leaves behind a residue that forms a visible message, such as “VOID” on the product. It is the most aggressive mode and is preferred when leaving a permanent mark is acceptable or required—such as in cardboard packaging or high-security seals.

Film delamination occurs when the facestock splits from the inner film layers. The void pattern appears on the peeled label, but the product’s surface remains clean. This is ideal for reusable items or clean surfaces like metal, glass, and electronic device enclosures. It’s used on products like laptops, phones, or lab equipment where leftover adhesive could block access to screws, damage housings, or interfere with reassembly during servicing.

In pattern release, the hidden message becomes visible within the label itself without leaving anything on the surface. A colour change or transparency shift usually reveals the pattern. This mode works well for non-porous surfaces or tamper indicators where the removed label will be inspected later.

Each failure mode exposes tampering differently; if the wrong mode is used, tampering might go undetected – or the label might trigger prematurely during routine handling.

For example, labels with aggressive adhesives may “void” on flexible plastics. Labels designed for rigid surfaces may delaminate at the edges if applied to curved enclosures. Selecting the correct failure mode prevents false alarms and ensures tamper evidence is reliable and meaningful.

Failure Mode | Visible Tamper Indicator | Residue Left on Surface | Recommended Surfaces | |

|---|---|---|---|---|

Adhesive Failure | Message stays on product surface | Yes | Cardboard, paperboard, textured plastics | |

Film Delamination | Message appears inside the label after peeling | No | Flat, hard surfaces like glass, metal, ABS | |

Pattern Release | Colour shift or text reveal within label | No | Clean, non-porous plastics, smooth retail packs |

Film delamination is preferred when tampering needs to be visible from a distance – like on returned devices, medical equipment, or locked panels – because the label warps or curls when removed. Pattern release is used when the label will be checked later, often off-site or during returns processing. It suits situations where subtlety is more important than visibility, and the label becomes evidence. Pattern release is also more cost-effective for high-volume applications, while film delamination costs more due to its layered construction and engineering.

Void labels have built-in stress points that fail when peeled. This failure is engineered at the layer where the facestock, adhesive, and void pattern meet.

During application, the adhesive forms a strong bond with the surface, while the void layer remains hidden between the film and adhesive. Once the adhesive sets, any attempt to lift the label disrupts this bond and triggers separation at a predefined interface.

As detailed in the previous section, each failure mode – adhesive failure, film delamination, or pattern release – triggers a different response. But in all cases, the separation is permanent.

Once the separation occurs, the message cannot be hidden or repaired. The label cannot be flattened, resealed, or realigned without visible damage. Delaminated layers curl or warp, transferred text stays bonded to the surface, and printed void patterns remain exposed.

The adhesive is pressure-sensitive and often chemically modified to resist removal techniques like heat or solvents. The void pattern is microstructured or pre-printed using coatings that only activate under peeling stress—not pressure or vibration.

Every element, film tension, adhesive strength, coating chemistry, and liner release force, is fine-tuned so that tampering causes predictable failure while normal handling does not.

When peeled, the void message is fully transferred to the product surface, leaving a permanent mark. The facestock often tears or warps during removal, and the adhesive splits cleanly to deposit the pattern. This type offers the most potent visual deterrent and is ideal for disposable packaging or cartons where surface marking is acceptable or required.

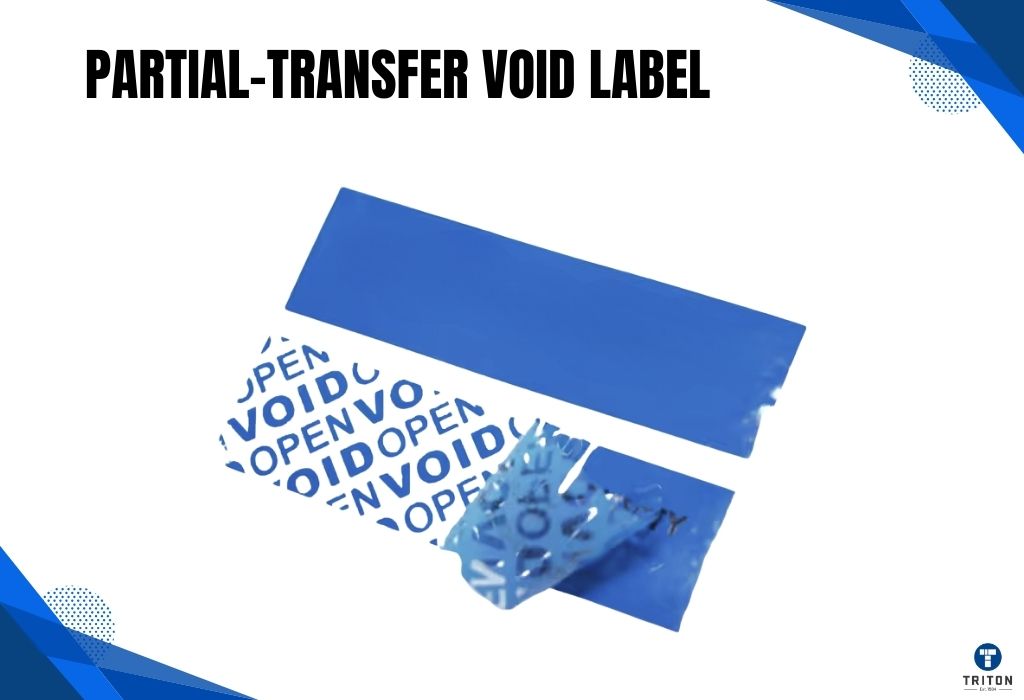

This type splits the void message between the label and the surface. Some adhesive and print remain on the product, while the rest stays on the peeled label. It balances visibility with easier cleanup. It’s commonly used on boxes, kits, or devices needing to be resealed or inspected later without full defacement.

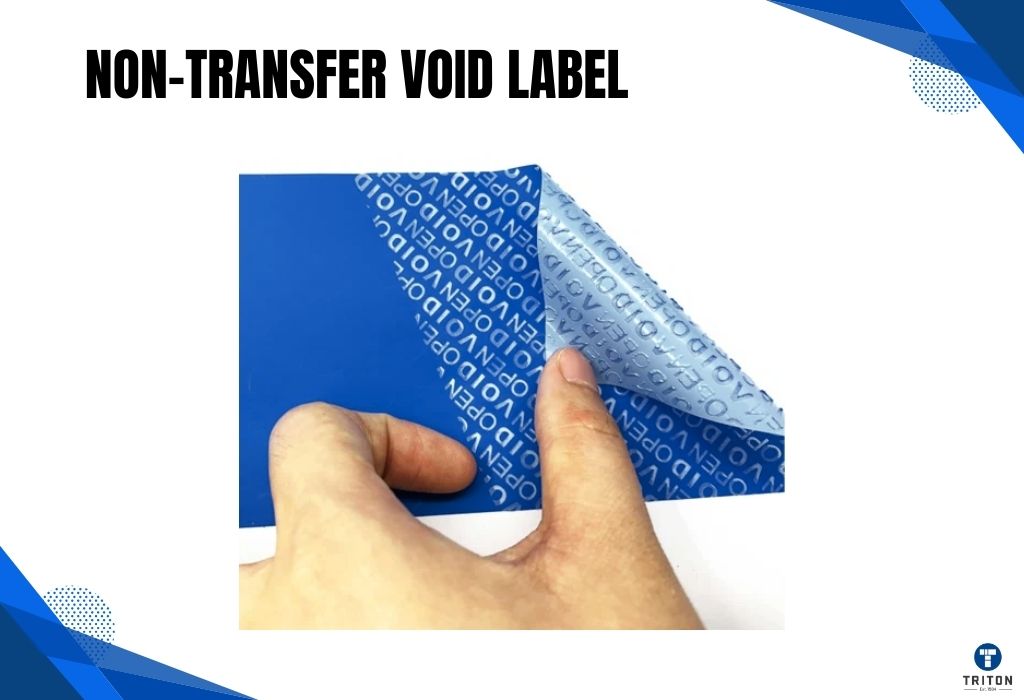

The void message appears only on the label when removed. The surface remains clean, with no adhesive or text left behind. This design suits reusable items, clean enclosures, or surfaces where a label leaving its residue is unacceptable. Tamper evidence is visible only on the removed label, which may need to be retained for inspection.

Custom message void labels work just like standard void labels but reveal a message tailored to the brand or application. Instead of a generic “VOID,” the label might display “WARRANTY VOID,” a company name, serial code, or logo. This makes counterfeiting harder and improves traceability. Custom messages can be built into full-, partial-, or non-transfer designs and are often used in asset tracking, electronics, automotive parts, and regulated goods where brand integrity and identification are critical.

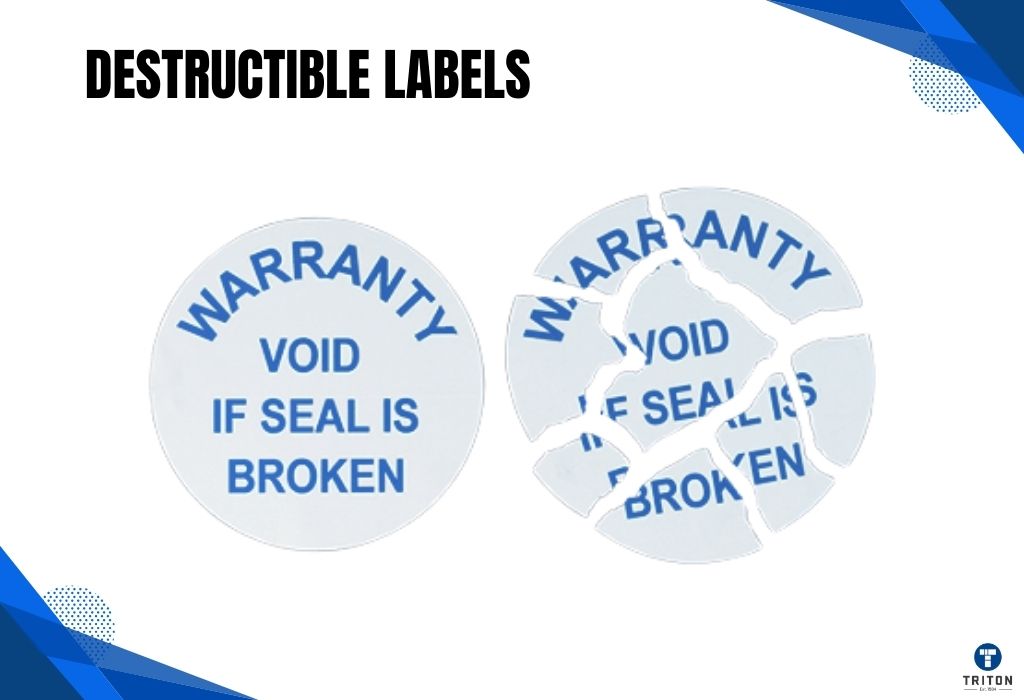

Destructible labels are not void labels strictly – they don’t reveal a hidden message. Instead, they use ultra-fragile facestock that shatters, flakes, or crumbles when peeled. This physical breakage prevents reapplication. Destructible labels are commonly used for screw covers, asset tags, and warranty seals. They are often applied instead of non-transfer void labels but can replace partial-transfer designs when clean removal isn’t required.

Type | Void Location | Residue on Surface | Typical Use Case |

|---|---|---|---|

Full-Transfer | On product surface | Yes | Box seals, pharma cartons

|

Partial-Transfer | Split (label + surface) | Partial | Test kits, equipment pack |

Non-Transfer | On label only | No | Electronics, reusable item |

Custom Message | On surface or label | Depends on base type | Warranty, asset tagging |

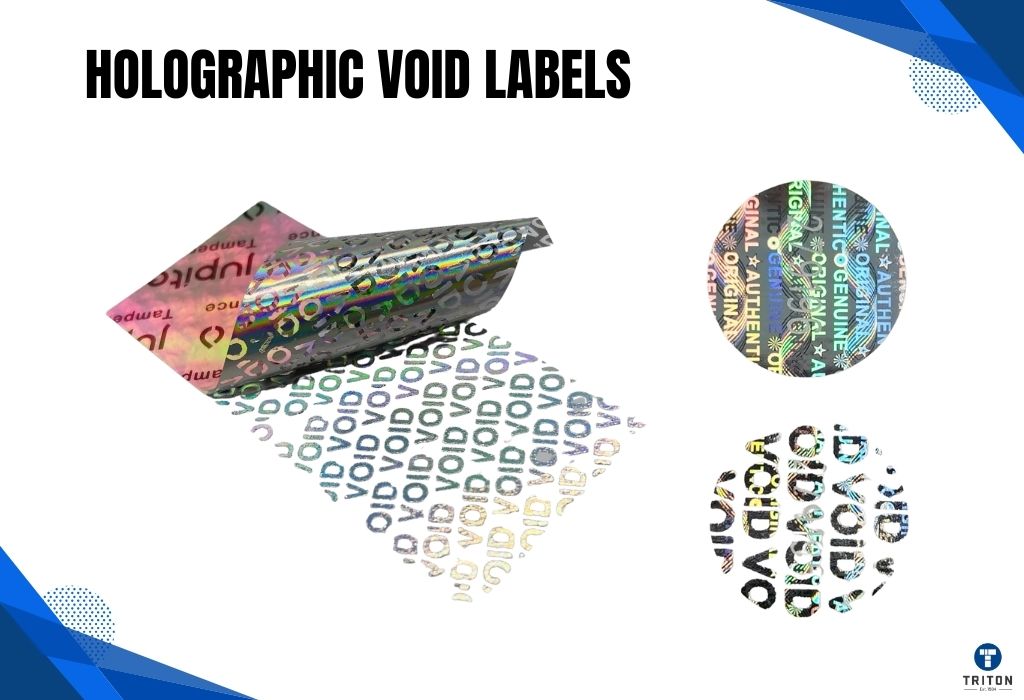

Holographic | Label + visual foil | Optional | Anti-counterfeit, ID cards |

UV-Reactive | Hidden layer (UV only) | No | Covert checks, high-security cargo |

Failure Modes vs Void Label TypesFailure mode refers to where and how the label breaks to show tampering – adhesive split, film delamination, or pattern shift. Void label type defines what is left behind: full, partial, or no transfer – and can use any failure mode. |

Void labels are used across sectors where packaging or product integrity must be verifiable at every stage. They provide low-cost, passive tamper evidence without requiring tools, power, or user training – making them ideal for high-risk, high-volume, or regulated environments.

In pharmaceuticals, void labels are applied to medicine packs, test kits, and clinical trial components. Regulatory frameworks like the EU Falsified Medicines Directive and ISO 21976 mandate tamper-evident packaging. Full-transfer and partial-transfer labels are widely used to leave clear evidence if a pack has been opened.

Electronics manufacturers use non-transfer void seals across screws, ports, and enclosures to void warranties and show device interference. These are common on laptops, hard drives, routers, and medical diagnostic equipment. Once removed, the void message appears on the label and cannot be reset.

In logistics and warehousing, void labels are used on cartons, pallets, and cargo doors to detect unauthorized access during transit. High-tack full-transfer labels leave residue on cardboard or shrink wrap to show that the packaging has been opened.

Retail brands apply custom or holographic void seals on high-value products such as cosmetics, perfumes, and electronics. These protect against product swaps and return fraud and help verify authenticity at the point of sale.

While void labels offer strong tamper evidence, they are not foolproof. Understanding their limitations helps choosing and using the right label effectively.

While void labels deter casual tampering, advanced attackers may bypass them using controlled heat, cold, or solvents to peel the label without triggering the void effect. Generic, low-spec labels are especially at risk. Hence, void labels must be part of a layered security system – not used alone.

The void effect depends on proper adhesion. Labels can fail on low surface energy (LSE) plastics (like PE, PP), oily metals, textured or curved surfaces, or if the surface is dirty or humid. Incorrect pairing of adhesive to substrate can cause premature detachment or prevent the void message from activating.

Void labels cannot be reused. Once activated, they are destroyed. For large-scale operations, the per-unit cost adds up quickly. Operational budgets must account for this recurring expense against the security risks involved.

Adhesives and facestock materials may chemically interact with certain surfaces—causing staining, residue, or degradation, especially on metals or speciality coatings. Thorough pretesting is essential to prevent surface damage, especially for high-end electronics, medical gear, or luxury packaging.

Choosing the correct void label is a five step process.

First, match the adhesive to the surface of the product. Is the product surface plastic, metal, or cardboard?

Second, account for environmental stress like heat, moisture, or chemicals.

Third, align the label’s tamper response with your security needs.

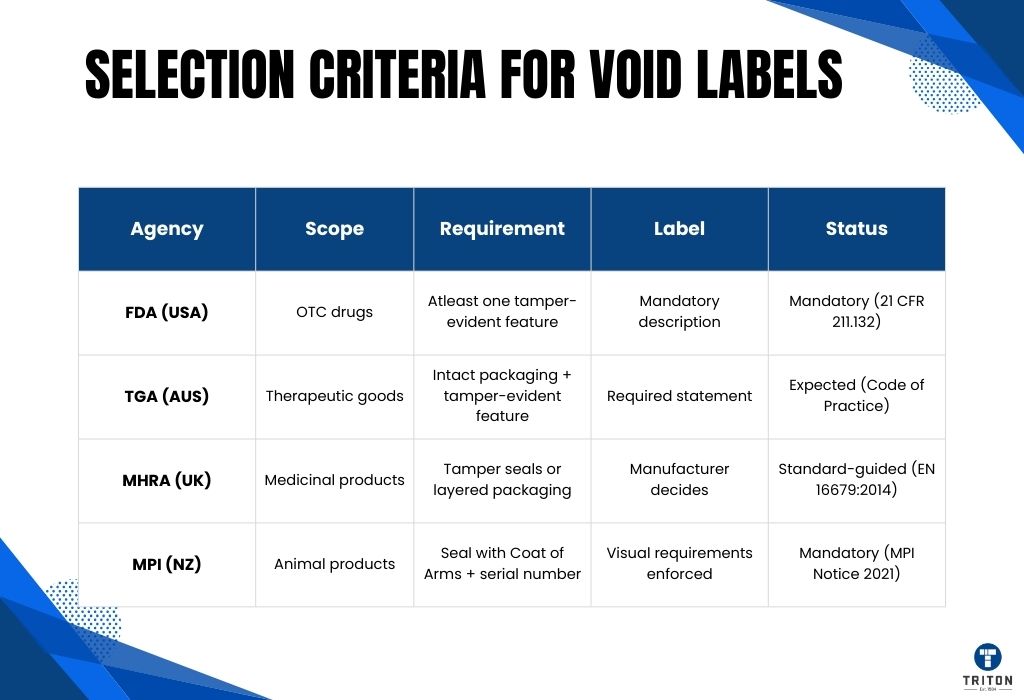

Fourth, ensure compliance with local standards – FDA (US), TGA (AUS), MHRA (UK), and MPI (NZ) all regulate tamper-evident packaging in specific sectors.

Finally, assess the need for custom features like serial numbers, logos, or QR codes for tracking or brand protection. A label that fits all five delivers reliable and compliant visible tamper protection.

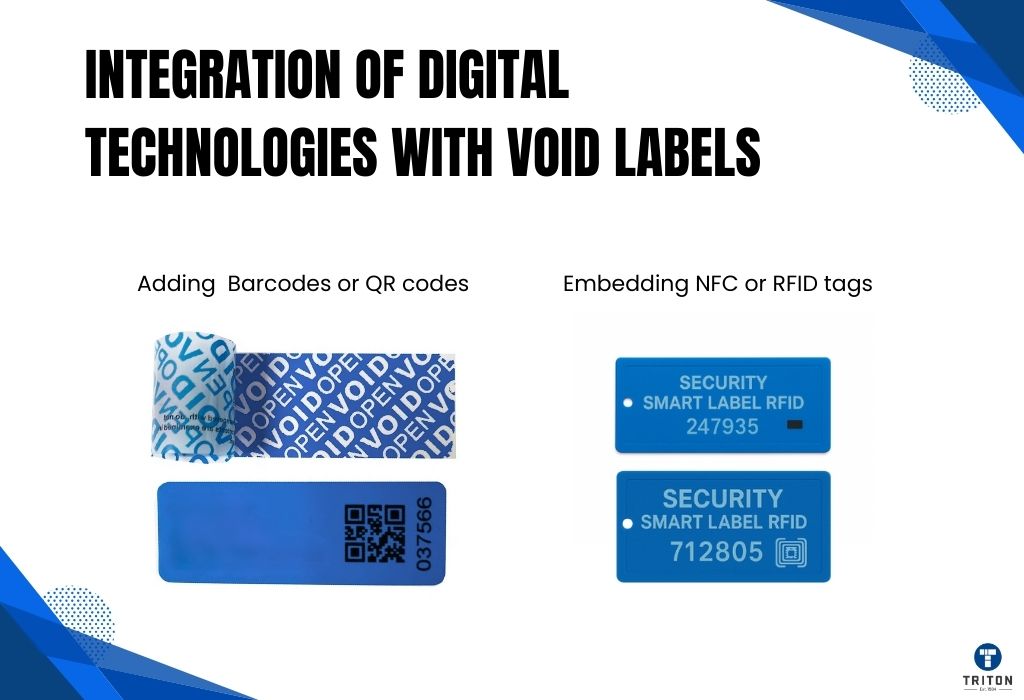

Marrying void labels with digital technologies bolsters product security and supply chain efficiency.

Serialization involves assigning unique identifiers, which improves traceability and authentication during the product lifecycle.

Adding barcodes or QR codes helps in inventory management and improves consumer engagement by linking to product information or promotions.

Embedding NFC or RFID tags allows real-time tracking and improved supply chain transparency.

Integrations transform void labels into solutions that deter tampering and enhance operational visibility and customer interaction.

Begin by testing void labels on actual packaging to confirm adhesion, surface compatibility, and performance under real-world conditions.

Train staff to apply labels correctly and recognize valid signs of tampering.

Set clear protocols for inspecting seals, logging breaches, and escalating incidents. Build these steps into existing QA or logistics workflows. Review and update label specifications regularly to keep up with new threats or material changes.

Tamper-evident labels are only effective when supported by process discipline, trained personnel, and routine oversight; without these, even the best-designed label can fail.

Void labels offer visible, irreversible protection against tampering across industries – from pharma cartons to electronics housings. But a label is only as good as where and how it’s used.

Performance depends on correct surface matching, environmental fit, and staff training. With the right type, failure mode, and digital features, void labels become trusted control points across the supply chain.

Looking for the right void label for your product or process?

Explore options on Triton. Compare types, request samples, and start testing today. Your product’s security begins with the correct label – Triton helps you get there faster.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below