Swing tags, also known as hang tags or product tags, are non-adhesive labels attached to merchandise. They communicate core data, such as brand, price, or barcodes, but also serve as a physical branding tool at the point of sale.

While most are made of paperboard, materials can also include plastic, leather, or fabric to reflect a product’s market position. A cord, plastic barb, or rivet fastens the tag to the item, often with a tagging gun. This method distinguishes them from adhesive or sewn-in labels. It prevents surface damage or residue, which is practical for clothing, coated materials, and sensitive equipment.

This article examines materials, print techniques, regional regulations, and design strategies.

Three components define a swing tag’s physical properties: construction, material, and finish.

Construction choices, like the thickness (GSM) of a single card and multi-page booklets, affect rigidity and space.

The material itself – paper, fabric, or synthetic film – dictates environmental resistance.

Finally, surface coatings add a layer of durability. We will now examine each component to understand its role in the final product.

Swing tags are built as either single-layer or multi-layer units.

Single-layer tags consist of one flat sheet. They are suitable for low-cost or straightforward labelling needs, such as price display or basic branding. These are common in mass-market apparel or accessories where minimal information is required.

Multi-layer tags provide additional space by using a folded or booklet format. These are used when more information must be included, such as garment care instructions, warranty terms, or legal notices. Booklet-style tags are often used in sectors where compliance or product guidance is crucial, such as the outdoor gear or electronics industries.

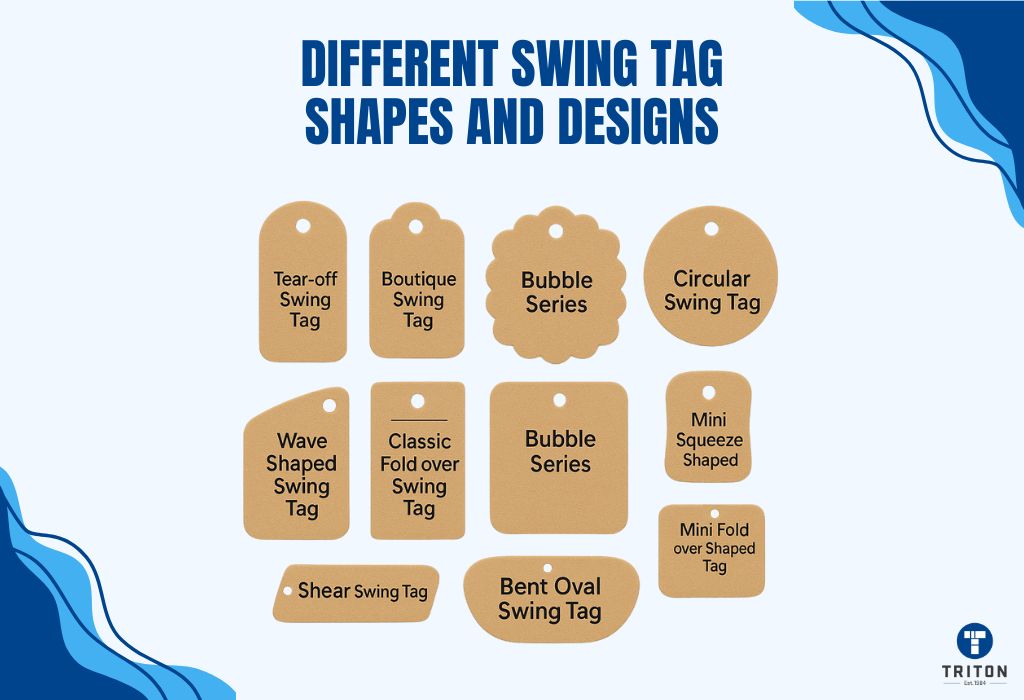

Most swing tags include a hole punched into the material to support fastening. The hole may be plain or reinforced with an eyelet, depending on the expected handling. Die-cut shapes are often used to enhance visual identity. For example, a tag might be cut to reflect a logo outline or specific brand geometry.

The material’s thickness, measured in grams per square metre (GSM), influences how rigid and durable the tag feels. Heavier GSM tags are more suitable for premium goods or environments involving physical contact or movement, such as equipment tags in warehouses.

The choice of material must account for product type, handling conditions, branding goals, print compatibility, and environmental performance.

Paperboard is the most widely used material for swing tags. It is printable, recyclable, and available in coated or uncoated finishes. Coated paperboard delivers sharper visuals and resists scuffing, while uncoated versions provide a textured, matte surface. GSM options vary to suit different strength requirements. FSC-certified paperboard is often used to meet sustainable sourcing criteria in retail packaging.

Kraft paper is unbleached and has a natural, untreated appearance. It is commonly used for short-term applications and eco-conscious branding. Kraft performs best in dry, indoor environments and is not recommended where high moisture or physical stress is expected. It is recyclable and biodegradable but supports limited print detail.

Polypropylene, polyethylene, and polyester are chosen for environments that demand resistance to water, abrasion, and chemicals. These substrates are used for swing tags on tools, outdoor goods, and products stored in cold or humid conditions.

They support UV inkjet, solvent-based, or thermal transfer printing. Many synthetic films are recyclable, and some are made from post-consumer recycled materials like rPET.

Textile-based materials, like woven cotton, polyester, and Tyvek, are selected when durability and tactile quality are important.

Tyvek, a high-strength polyethylene fibre, is tear-resistant and waterproof, and is ideal for industrial and outdoor use.

Fabric tags are used in high-end fashion, reusable items, or rugged gear.

Swing tag producers use recycled paperboard, rPET films, and biodegradable synthetics to meet sustainability targets and comply with regulations. These materials satisfy Extended Producer Responsibility (EPR) policies in markets like Australia and the EU. EPR makes a producer responsible for its packaging after disposal, so choosing materials that are recyclable or biodegradable is a direct compliance strategy.

Coatings are applied to the surface of the tag to improve performance, enhance aesthetics, and extend usability in demanding environments.

UV varnish creates a transparent, protective layer that also resists abrasion and improves colour vibrancy. It is often used for high-end tags where visual clarity matters, such as in premium apparel or electronics.

Lamination bonds polypropylene or polyester polymer film to a tag’s surface using heat or pressure. Lamination adds rigidity and protects the hang tag against tears, creases, and moisture. A gloss finish makes the colors more vibrant, while a matte finish reduces glare and hides fingerprints.

Laminating paperboard provides water resistance for items in high-handling environments or those with incidental moisture contact, such as in fitting rooms. The process does not, however, make the tag waterproof. Moisture can eventually penetrate the unsealed edges, causing the paper core to swell and the polymer film to delaminate.

Applications that demand complete immunity to liquids – for outdoor equipment, marine hardware, or refrigerated products – require an inherently waterproof substrate. Tags made from synthetic materials like polypropylene and Tyvek meet this specification.

Swing tags are attached to products using a variety of fasteners. The correct method depends on the product’s size, material, weight, and the conditions in which it is handled or displayed.

String or cord is the most common fastening method. It is suitable for garments, accessories, and other retail items where the tag must be easily removed without the use of tools. Cotton, jute, or polyester cords are used depending on brand preference and environmental goals.

Plastic loop fasteners provide a tamper-evident seal. They are used in retail logistics, electronics, or items that require secure but non-permanent attachment. These loops can be applied quickly and often do not require additional tools.

Wire or elastic ties are chosen for industrial tools, hardware, or bundled goods. Wire offers strength and holds shape, while elastic can stretch to accommodate bulky or irregularly shaped items. These are typically used in settings where tags may be subject to pulling or vibration.

Rivets or eyelets are used when the tag must stay attached under stress. These methods reinforce the tag hole and prevent tearing. They are suitable for outdoor goods, heavy equipment, or warehouse stock items that are frequently transported or handled.

Swing tags are available in standard and custom configurations. Shape and size significantly impact how well the tag fits the product, displays essential information, supports barcode readability, and integrates seamlessly into retail or logistics workflows. Size also influences material use, die-cutting efficiency, and attachment options.

Several shapes are widely used in commercial and industrial applications:

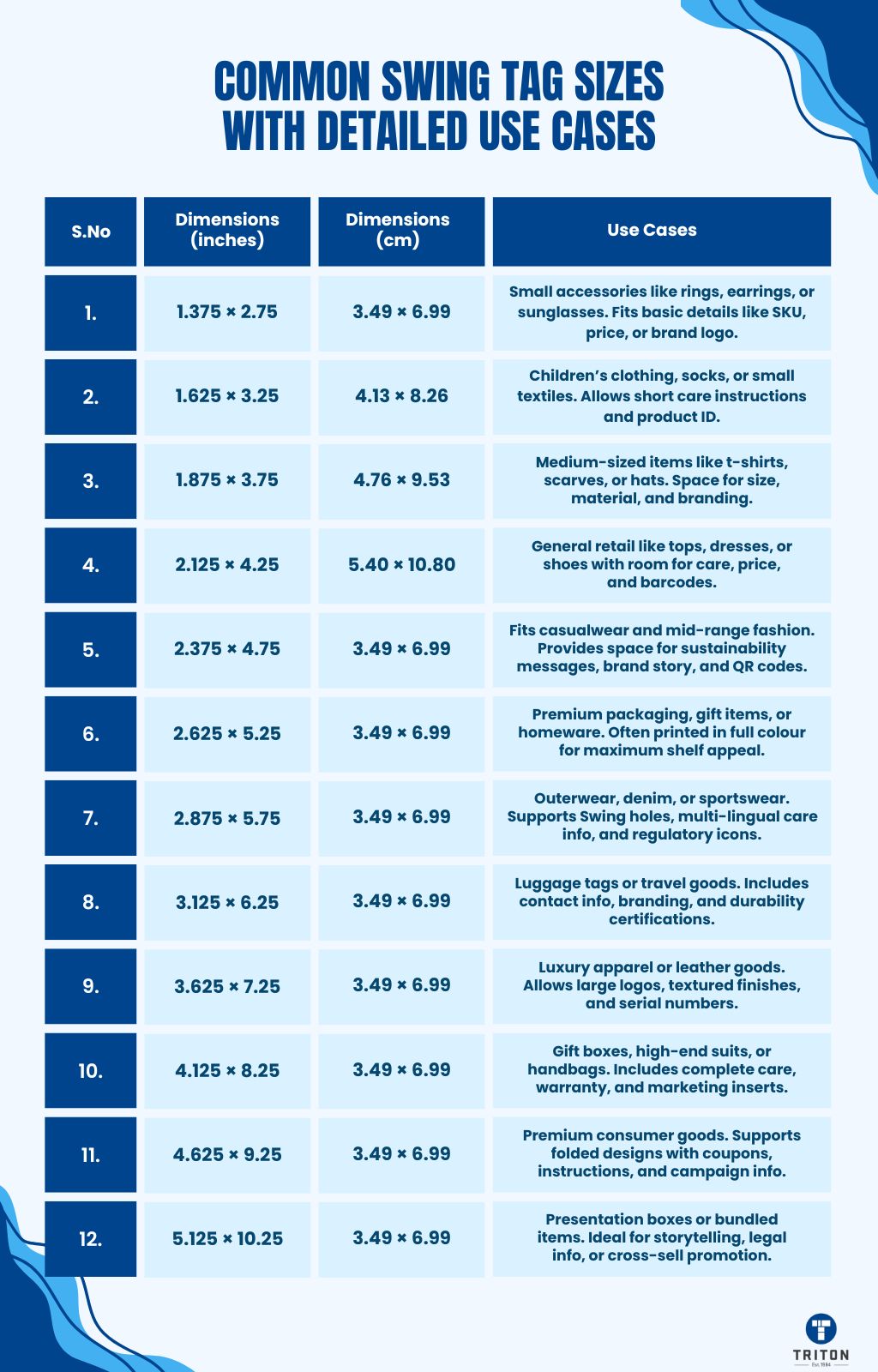

Tag size affects information capacity, visibility, attachment strength, and scannability. Standard dimensions used across retail and industrial settings include:

Size | Dimensions (inches) | Dimensions (cm) | Typical Use |

|---|---|---|---|

1 | 1.375 × 2.75 | 3.49 × 6.99 | Ideal for smaller items like jewellery or accessories. Provides enough space for basic information without overwhelming the product. |

2 | 1.625 × 3.25 | 4.13 × 8.26 | Suitable for small to medium-sized products, commonly used in children’s clothing. |

3 | 1.875 × 3.75 | 4.76 × 9.53 | Offers more room for branding and detailed information, fitting for medium-sized products. |

4 | 2.125 × 4.25 | 5.40 × 10.80 | Considered the standard size for tags, providing a perfect balance between usability and aesthetic appeal.

|

5 | 2.375 × 4.75 | 6.03 × 12.07 | A versatile size, good for a variety of products, offering a balance between information and design. |

6 | 2.625 × 5.25 | 2.625 × 5.25

| Offers the opportunity for companies to incorporate their brand colour as the background, creating a visually appealing look. |

7 | 2.875 × 5.75 | 7.30 × 14.61 | Provides a custom fit for paper swing tags, suitable for creatively designed tags. |

8 | 3.125 × 6.25 | 7.94 × 15.88 | Ideal choice for printing luggage tags, offering enough space for important information. |

9 | 3.625 × 7.25 | 9.21 × 18.42 | Excellent for high-end products where detailed storytelling and branding are key. |

10 | 4.125 × 8.25 | 10.48 × 20.96 | Perfect for making a bold statement and stands out easily. |

11 | 4.625 × 9.25 | 11.75 × 23.50 | Used for premium products, providing ample space for branding, imagery, and text. |

12 | 5.125 × 10.25 | 13.02 × 26.04 | The largest standard size, ideal for high-end products or items requiring extensive information. |

When selecting tag dimensions, businesses must account for:

Final sizing should be verified through test runs across production, packing, and retail environments to confirm legibility, durability, and fit-for-purpose performance.

The printing method and content layout used on swing tags affect legibility, durability, and compliance with retail and industrial requirements.

Swing tags are produced using standard printing techniques like offset printing and digital printing. Operational needs, substrate types, and data formats dictate the print method.

Offset printing is used for high-volume production. It delivers consistent colour, sharp detail, and high throughput. This method is widely used on paperboard tags in retail settings where high-quality graphics and brand presentation are essential.

Digital printing is great for low-to-medium print volumes. It has fast turnaround, gives high-resolution output, and can handle variable content. Digital presses can handle a range of materials, including coated paper, uncoated stock, and synthetic films. This method is commonly used for promotional tags, small-batch items, and limited editions.

Thermal transfer printing can also handle dynamic information such as barcodes, serial numbers, and expiry dates. It is widely used in warehousing, logistics, and manufacturing environments where tags are printed or updated during packaging or dispatch. This method requires substrates with thermal transfer coatings and uses resin or wax-resin ribbons for durability.

The printing method must be compatible with the substrate. Coated materials may require quick-drying or UV-cured inks. Uncoated papers absorb ink faster but may produce softer images. Synthetic films need ink formulations with strong adhesion, such as solvent-based or resin inks, to resist smudging and wear.

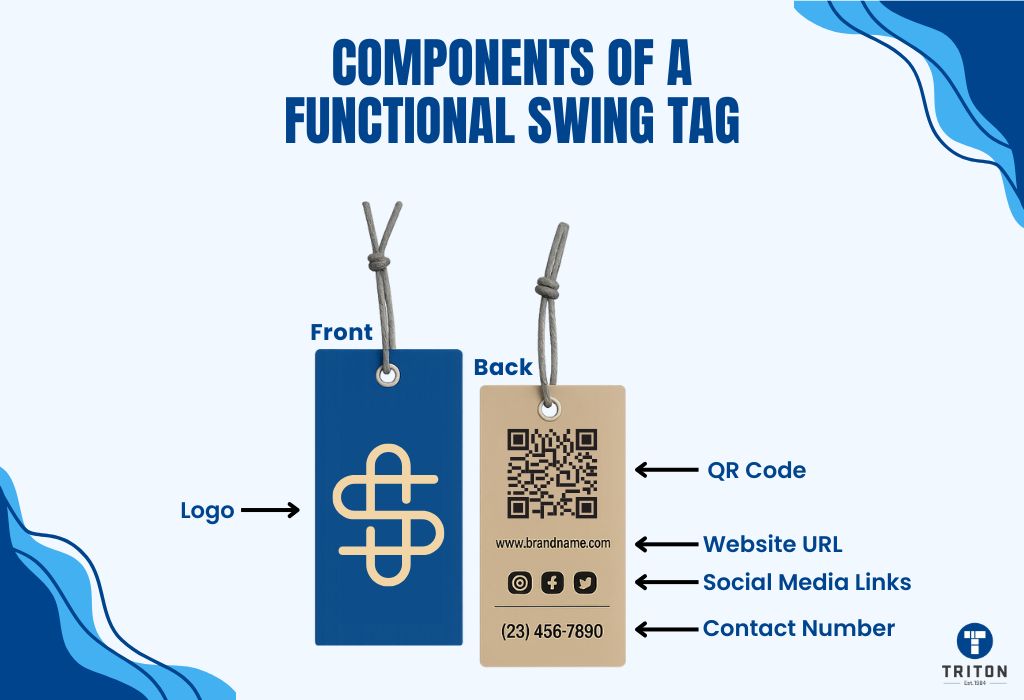

Swing tags contain both fixed and variable information. The layout must be readable, well-organised, and compliant with regional labelling standards. It should also support fast scanning and clear visual grouping.

Typical content includes:

Content must be arranged to ensure easy readability and functional use. Barcodes and QR codes must be printed with sufficient resolution and contrast to guarantee successful scanning. Font sizes and spacing must support legibility in retail lighting and packaging conditions. The design should strike a balance between white space and information density without overcrowding the tag.

Swing tags used across apparel, electronics, toys, furniture, cosmetics, and industrial goods must comply with regional labelling laws. Requirements vary by jurisdiction and product type. Missing or inaccurate swing tag information can result in fines, recalls, or import refusals.

Tags must remain legible, securely attached for the duration of the product’s expected lifecycle, and printed in the official language(s) of the destination market.

Under the Australian Consumer Law (ACL), textile swing tags must show fibre content, size, country of origin, and business contact details. Care instructions should follow AS/NZS 1957:1998. Tags must be durable and legible for the product’s life span.

Environmental claims (e.g. “eco-friendly”) must comply with ACCC’s Green Marketing Guide. Toys may require age warnings or hazard statements under the Consumer Goods (Toys for Children up to and including 36 Months of Age) Safety Standard 2020.

Under the Textile Products (Labelling and Fibre Composition) Regulations 2012, textile swing tags must disclose fibre composition using approved terms. Country of origin is encouraged. Optional care symbols must follow BS EN ISO 3758:2012 if included.

Tags for toys must include CE markings in accordance with the Toys (Safety) Regulations 2011. Electrical items may also require conformity marks based on product type.

Textile swing tags are regulated under EU Regulation No. 1007/2011. Fibre content must be shown in descending weight using standardised names. Tags must be legible, fixed securely, and printed in the official language of the sale country.

Care symbols are not mandatory but are expected. Toys, PPE, and electronics are required to carry CE marks under EU safety directives. Environmental claims must follow EU Ecolabel Regulation No. 66/2010.

FTC regulations require textile swing tags to display fibre content, country of origin, and the identity of the manufacturer or distributor. These rules fall under the Textile Fiber Products Identification Act, the Wool Products Labelling Act, and the Care Labelling Rule. Care guidance must appear in English or via approved symbols.

Toys and children’s products must meet the requirements of CPSIA Section 103, which mandates the use of permanent tracking labels. Electrical products require FCC identification under 47 CFR Part 15.

Swing tags are also required or recommended across other regulated sectors to provide visibility of safety and compliance data.

Tags must include the manufacturer’s identity, country of origin, batch number, age grading, and any applicable hazard warnings. In the EU and UK, CE marking is mandatory. In the US, CPSIA requirements apply.

Tags display model numbers, voltage, safety warnings, and disposal icons. EU products must comply with directives on low voltage, electromagnetic compatibility (EMC), and waste electrical and electronic equipment (WEEE). US goods must follow FCC labelling rules. UK items require UKCA marks.

Tags for furniture often state fire safety compliance and material disclosures. In the US, this includes 16 CFR Parts 1630 and 1631, as well as California SB 1019. UK furniture must comply with the 1988 Fire Safety Regulations.

Industrial swing tags display inspection records, safety warnings, or traceability codes. In Australia, they may fall under the Work Health and Safety (WHS) regulations. In the US, OSHA and ISO documentation practices influence the content and design of tags.

While primary packaging bears the most required information, swing tags on gift sets, or multi-packs must not misrepresent the product. Where used, tags must show ingredients, allergens, shelf life, and claims such as “organic” or “hypoallergenic” in line with:

Swing tags are used across industries for compliance, identification, marketing, and inventory tasks. Here are common use cases:

Swing tags are widely used on clothing, footwear, and accessories. Common content includes:

These tags are often tailored to align with brand design or seasonal campaigns.

Swing tags on furniture, fixtures, and tools communicate key product details such as:

Tags in this sector often use waterproof or laminated materials due to the handling and environmental exposure they undergo.

In warehousing and shipping, swing tags act as temporary labels for:

Tags must remain legible under warehouse conditions and support quick scanning.

Swing tags used on tools and machinery provide:

These tags are typically made from tear-resistant or chemically resistant materials, such as polypropylene.

Swing tags support marketing and promotional functions, including:

Using foil, embossing, or die-cutting for added shelf appeal

Advantages of Swing Tags | Limitations and Considerations |

|---|---|

Depending on the material (e.g. paperboard, kraft), tags can be reused or recycled. | Manual tagging increases time and labour costs in high-volume production settings. |

Facilitates a cleaner purchasing experience without adhesive residue. | Tags may be lost or separated during transit if not securely fastened to the product. |

Larger format allows inclusion of care instructions, barcodes, return terms, and branding. | Not suitable for humid, wet, or outdoor conditions unless waterproofed or laminated. |

Can be designed with custom shapes or premium finishes to reinforce shelf-level branding. | Custom designs or durable substrates may increase unit cost compared to basic adhesive labels. |

Does not damage delicate surfaces such as fabric, leather, or coated finishes. | Tags can be removed without leaving evidence, limiting security in retail environments. |

Swing tags can be customised based on branding, durability, and compliance needs across local and export markets.

Effective swing tags must be designed and applied to withstand handling, meet regulations, and support supply chain processes.

Include barcodes or QR codes for scanning. Position them to work across packaging, distribution, and retail systems.

Swing tags are multifunctional labelling tools that serve critical roles across diverse industries, including retail, logistics, manufacturing, electronics, and regulated consumer goods.

Well-designed swing tags enhance customer experience, streamline inventory management, and support market access by meeting legal labelling standards in local and export markets.

Explore our range of label printers and branding machines built for precise and efficient labelling.Visit the Triton Store to find the right printer for your operation.

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below