In a market flooded with countless beer options, distinguishing your beer on the shelf has become more challenging than ever. The key to differentiation? Innovative and strategic beer packaging.

More than just an aesthetic choice, effective packaging acts as a silent salesman—enticing consumers, conveying your brand’s ethos, and preserving the beer’s quality. It emerges as a multifaceted tool that, when adeptly utilised, can significantly boost a brand’s visibility and appeal.

This guide is designed to equip beer manufacturers, especially those in the craft beer sector, with comprehensive insights into the strategic significance of packaging. This guide discusses the different beer packaging options. It offers a practical roadmap to deploying exemplary packaging solutions that resonate with your brand identity and consumer expectations.

With the stage set, let’s start by learning why beer packaging is important.

In the vast and varied landscape of the beer industry, packaging is not just a container but a critical component of a brand’s success. It plays a pivotal role in several key areas:

The primary function of packaging is to protect the beer from physical, chemical, and biological contamination. This includes protection from light exposure, oxygen, and temperature fluctuations, which can all affect the beer’s taste & flavour and shelf life. During shipping, robust packaging also prevents breakage and leakage, ensuring the product arrives in optimal condition.

First impressions are lasting. The design and quality of beer packaging are consumers’ first point of contact with your brand.

Well-designed packaging can attract new customers, encourage trial purchases, foster brand recognition, and even influence taste perceptions before the bottle is ever opened.

Packaging is a powerful medium for storytelling. It communicates your brand’s ethos, values, and uniqueness. Through design elements like logos, colours, textures, and materials, packaging can express the craftsmanship, heritage, or innovation behind your beer, creating a deeper connection with consumers.

In a crowded market, distinctive packaging can set your beer apart. Innovative designs, unique materials, or interactive elements can make your product stand out on the shelf, turning casual browsers into buyers.

Beer packaging serves as a canvas for necessary legal information, including alcohol content, ingredients, and regulatory warnings. This information can be integrated into the design in a way that complements the brand’s image and aids in consumer education.

For a deeper understanding of the complexities of labelling alcoholic beverages and navigating regulatory requirements in Australia, refer to our comprehensive guide: Understanding the Labelling of Alcoholic Beverages.

Packaging in the beer industry is strategically categorised into three main levels: primary, secondary, and tertiary. Each type plays a distinct role in the product’s journey from the brewery to the consumer.

Primary packaging is the beer’s first line of defence, directly containing the product. It is crucial in preserving its freshness, flavour, and overall quality. This packaging serves as the consumer’s direct point of contact and significantly contributes to brand identity.

Secondary packaging groups primary packages together, simplifying handling, distribution, and sales processes. Tertiary packaging, on the other hand, is designed for the bulk handling and transportation of beer, focusing on the safe and efficient delivery of the product from the brewery to distribution centres and retailers.

For a deeper understanding of these three packaging types and their impact on the product and the market, our comprehensive guide, Understanding Primary, Secondary, and Tertiary Packaging, offers valuable insights and practical advice.

Glass bottles have long been a traditional choice for beer packaging, valued for their ability to preserve the beer’s purity, taste and quality. They are typically available in various colours, such as brown, green, and clear varieties.

Brown-coloured beer bottles are especially favoured as they offer the best protection against UV light, which degrades hop compounds and alters the beer’s flavour.

Aluminium cans have surged in popularity due to their lightweight, recyclability and superior ability to block light and oxygen. Their convenience for transport and increasing acceptance among both craft beer enthusiasts and mainstream consumers have made them a popular choice among brewers.

Cans also provide a broad canvas for creative label designs, enhancing brand visibility.

Kegs, typically made from metal (though sometimes plastic), are the primary vessel for dispensing beer. They feature a tube that extends to the bottom and a ball-lock mechanism for sealing, allowing gas to push the beer through the tube when connected to a tap coupler. This simple yet effective system—gas in, beer out—makes kegs essential for distributing beer in larger quantities for on-premise consumption in bars, restaurants, and events.

Kegs stand out as an environmentally sustainable packaging choice because they can be reused and effectively serve larger quantities of beer, contributing to reduced waste.

Cardboard boxes are a staple in beer packaging, used to group individual units like bottles or cans for easier transportation and storage. These beer packaging boxes are constructed from cardboard, offering a sturdy yet lightweight solution to protect the beer during transit.

The outer surfaces of these cardboard boxes present an opportunity for breweries to print marketing messages, logos, and other brand-related visuals, making them an effective tool for brand reinforcement. Their recyclability also aligns with growing consumer demand for sustainable packaging options.

Six-pack carriers are specifically designed for consumer convenience, allowing for the easy carry of six individual beer containers, usually bottles or cans. Typically made from sturdy cardboard or occasionally plastic, these carriers are engineered to support the weight of six full beer containers while providing a comfortable grip.

The design of six-pack carriers often incorporates extensive custom design, including vivid graphics and product information, which helps attract consumer attention on crowded retail shelves. They bridge the gap between functionality and marketing, offering breweries a canvas to engage with their audience further.

Shrink wrap is a plastic film wrapped around a product or group of products and then heated to form a tight seal. In beer packaging, shrink wrap is commonly used to bundle together multipacks of cans or glass bottle. This method is valued for providing a clear view of the product while offering a degree of protection from dust, moisture, and tampering.

Although shrink wrap does not offer the same branding opportunities as cardboard boxes or carriers, it efficiently creates easy bulk packages to handle and transport.

Pallets serve as the base for stacking and securing cardboard boxes or shrink-wrapped products. Made from wood, plastic, or metal, pallets facilitate the easy loading, unloading, and transportation of beer packages with forklifts and pallet jacks.

Pallets are designed to be durable and reusable, accommodating significant weight and providing stability during transport. Palletisation maximises space in storage and shipping containers, reducing shipping costs and minimising product damage.

Stretch wrap, a highly stretchable plastic film, is used to secure products tightly. It wraps around items to keep them bound and stable, protecting them from shifting or falling during transportation.

Stretch wrap offers additional protection against dust, moisture, and tampering, ensuring the products remain intact and clean throughout the logistics chain. Its transparency allows for easy inspection of goods without unpacking, facilitating quicker processing at distribution centres.

For larger shipments, corrugated cases are used to group secondary packages, providing an extra layer of protection. These heavy-duty boxes are made from corrugated fiberboard, offering superior strength and durability for bulk transport.

Corrugated cases can be stacked on pallets, optimising space utilisation and safeguarding the products against impacts and compressive forces. Like cardboard boxes, corrugated cases can also be customised with branding and handling instructions, contributing to brand visibility and ensuring proper handling during transit.

Barrels, traditionally made from wood but also available in metal and plastic variants, are used for storing and transporting large quantities of beer. Wood barrels, in particular, can impart additional flavours to the beer, a characteristic sought after in certain styles.

Barrels offer a unique combination of storage and ageing capabilities, making them valuable for transportation and the brewing process. In the context of tertiary packaging, barrels are often used with pallets and stretch wraps to ensure their stability and integrity during transport.

Here is a step-by-step guide to help you with beer packaging.

Start by assessing your beer’s unique characteristics and target market to determine the most suitable packaging.

Consider factors such as product volume, shelf life, distribution channels, and environmental impact while deciding what kind of packaging will suit your purpose. This initial step ensures your packaging aligns with both consumer expectations and logistical needs, setting a solid foundation for the design and production process.

Budgeting is critical, encompassing both direct and indirect packaging costs:

Conducting a thorough competitive analysis is critical in distinguishing your beer packaging in a saturated market. This involves examining the packaging strategies of direct competitors and identifying trends within the broader beer industry.

Focus on elements such as design aesthetics, packaging materials, sustainability practices, and technological innovations used by competitors. Assess how these brands position themselves through their packaging and the impact it has on consumer perception and market share.

Identify gaps in the market where your packaging can offer something unique, whether it’s through innovative design, eco-friendly materials, or enhanced functionality.

Ensure your packaging design incorporates all necessary information, including branding, product details, barcodes and legal requirements. This step is crucial for consumer engagement and regulatory compliance.

If you are looking to enhance your knowledge of barcoding technology and its vast landscape, delve into our curated collection of informative guides:

For an extensive dive into the world of barcodes and to access a plethora of additional resources, please visit our Barcode Learning Centre. Within this expansive knowledge hub, you’ll find a wealth of information designed to equip you with a comprehensive understanding of barcode technology and its effective implementation across various industries.

Integrating your packaging with innovative marketing strategies. This approach enhances your product’s appeal and provides a direct communication channel with your consumers.

Here’s how to effectively blend packaging with marketing innovations:

Choosing the right printing method is crucial, as each offers distinct advantages tailored to different design needs, production volumes, and budgetary considerations. Below is a breakdown to help guide your decision:

Digital printing shines in its flexibility, making it ideal for craft beer packaging. It allows for producing small batches with detailed, vibrant designs at a reduced cost. This method is particularly well-suited for limited edition releases, seasonal offerings, or customised packaging campaigns, offering the ability to quickly adapt designs with minimal financial impact.

Offset lithography excels in producing large volumes of high-quality prints, positioning it as the go-to choice for craft beer brands with wide distribution networks. It guarantees consistent colour and image quality across all packaging, a critical factor for preserving brand integrity.

Ideal for standard beer labels and boxes that demand uniformity and precision across extensive production runs, offset lithography offers a cost-efficient solution for craft breweries planning to expand their reach and maintain consistent packaging aesthetics.

Flexography stands out for its speed and versatility, which is compatible with a broad range of packaging materials such as labels, flexible plastics, and corrugated boxes. It’s highly effective for craft beer packaging that requires high-volume production without sacrificing quality.

The main advantage of flexography is its efficiency in processing large orders, making it perfect for breweries distributing diverse product lines. This method suits standard packaging designs needing vibrant, uniform colours and durability.

Screen printing is renowned for producing rich, textured designs, adding a layer of tactile and visual depth to craft beer packaging. It involves applying thick, opaque inks, ideal for crafting premium packaging features like logos and special edition labels directly onto bottles or cans. Screen printing offers breweries the opportunity to highlight their artisanal brand qualities or to market limited releases with a distinct, upscale look.

Artwork preparation and finalisation is the stage where your craft beer packaging design comes to life, ready for printing. This process involves refining the visual elements of your packaging, such as graphics, logos, and text, ensuring they are perfectly aligned and meet printing specifications. Here’s how to navigate this crucial step:

The integration of barcodes into labels is not just a matter of regulatory compliance but also a strategic component of inventory management and sales tracking.

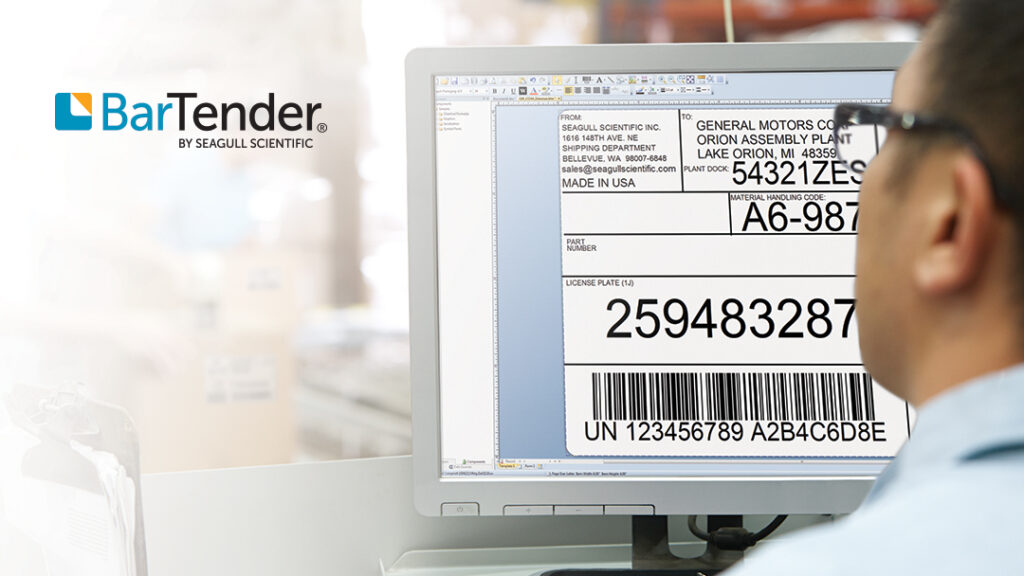

While the allure of free barcode generators is undeniable, primarily due to their cost-saving appeal, these tools often fall short of meeting the demands of professional-grade operations. This is where Seagull Scientific’s BarTender Software comes into play, offering a robust, reliable, and comprehensive solution that far surpasses the capabilities of free alternatives.

BarTender software is an advanced label design and printing software that enables the efficient creation of labels, barcodes, RFID tags, and more. Designed to cater to the needs of professional environments, BarTender distinguishes itself through:

For a deeper exploration of BarTender’s capabilities and how it can revolutionise your beer packaging process, refer to our comprehensive What is BarTender? guide.

At Triton Store, we offer the full suite of BarTender software editions to suit various business sizes and needs, including:

Additionally, we provide BarTender Cloud, a cloud-based solution that facilitates remote label printing and management, offering unparalleled flexibility and accessibility.

For insights into how BarTender Cloud compares with the on-premise BarTender software, our BarTender Cloud vs BarTender Software guide is an invaluable resource.

Effective beer packaging is essential for standing out in the competitive craft beer and draft beer market. This guide has outlined the critical steps from initial design to production and logistics, ensuring your product captures your brand’s essence and appeals to consumers.

By meticulously following these steps, breweries can create custom beer packaging that looks great and resonates with their target audience, ultimately contributing to the brand’s success.

We hope this article was useful.

Thanks for reading!

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below