For manufacturers and retailers, optimising product presentation on store shelves is a critical aspect of the retail strategy. Enter Shelf-Ready Packaging (SRP) and Retail-Ready Packaging (RRP), two methodologies designed to enhance efficiency and in-store aesthetics.

In straightforward terms, shelf-ready packaging and retail-ready packaging are two interchangeable terms that describe a packaging approach where products are delivered to retailers in a manner optimised for direct shelf display. This streamlined approach negates the need for additional unpacking or individual product arrangement, saving both time and labour costs. Beyond mere packaging, these terms encapsulate a “ready-to-sell” strategy, occasionally referenced by the French term prêt-à-vendre (PAV).

With the retail industry’s ever-evolving demands and challenges, mastering the subtleties of SRP and RRP is paramount for manufacturers and retailers alike. This article provides an in-depth exploration of these packaging strategies, emphasising their variations, benefits, and their instrumental role in refining retail operations. Let us begin by understanding what ready packaging really means.

Ready packaging is a modern approach to product packaging that prioritises both efficiency and presentation. It’s designed with the end goal in mind: to ensure that products are packaged in a way that they can be directly displayed or sold without the need for further preparation or handling by the retailer.

The concept behind ready packaging is to minimise the steps between receiving the product shipment and having it available for the consumer. The ready packaging concept offers two major benefits: first, it curtails labour and handling costs for retailers; second, it ensures that products are displayed consistently and appealingly across all retail outlets.

Consider the example of a popular brand of cookies. In traditional scenarios, these cookies will be shipped in large boxes, requiring store employees to open the box and individually stock each packet on the shelves.

With ready packaging, the same cookies could be shipped in a display-ready tray or carton. Retailers can simply place this tray directly onto the shelf, making the cookies immediately available for purchase. Moreover, the packaging is designed to be visually appealing, ensuring that the product stands out on the shelf and attracts consumers.

Did you know packaging is categorised into three distinct types? Dive into our comprehensive article on primary, second and tertiary packaging to gain a deeper understanding and insights into each layer.

Shelf-ready packaging (SRP) and retail-ready packaging (RRP) are terms often used interchangeably. They both describe a packaging strategy where products are delivered to retailers in a ready-to-display format, eliminating the need for additional unpacking or individual product arrangement. Essentially, both terms represent a “ready-to-sell” approach.

More specifically, “shelf-ready” pertains to cases designed for easy opening and display on shelves, ensuring products like pouches, small boxes, cans, or jars remain upright and accessible to customers.

On the other hand, “retail-ready” typically refers to shoppable displays or pallets commonly found in club and warehouse settings.

Within the extensive landscape of product packaging, manufacturers and retailers are presented with a diverse range of options tailored to address specific requirements. These packaging types not only guarantee product protection but also augment shelf attractiveness, making them crucial in the retail environment.

The following different types of shelf-ready and retail-ready packaging are discussed below.

Blister packs and clamshells are transparent plastic packaging solutions designed to both protect and showcase products. Made from hard, clear plastic, these packaging types are especially favoured for items where visual appeal is a key selling point.

Blister packs and clamshells ensure that the product is securely sealed yet fully visible, allowing consumers to evaluate the product without breaking the seal, ensuring product safety and integrity. This design not only ensures product safety but also serves as a theft deterrent, making it a popular choice for high-value or aesthetically appealing items.

Use Cases: Electronics, beauty products, toys, and other items where showcasing the product’s design or features is essential.

Hang-sell packs are a distinctive packaging design for products that benefit from vertical display. These packs have a pre-formed hole or hook, allowing them to conveniently hang on pegs or display stands in retail environments. The vertical display only optimises space and also ensures that the product stands out, catching the consumer’s eye at their eye level or above.

The design of hang-sell packs is particularly advantageous for products that are either too small to stand on their own on shelves or those that need to be differentiated from a sea of similar products. By elevating the product, retailers can ensure better visibility and accessibility, making it easier for consumers to locate and purchase.

Use Cases: Snacks, drinks, tools and accessories, stationery items, and any product benefitting from elevated, vertical display in retail settings.

Display boxes are a versatile packaging solution that combines the sturdiness of materials like corrugated cardboard with elements designed to enhance product visibility, such as clear windows or cut-outs.

The standout trait of display boxes is their dual-purpose design. The box itself ensures the product’s safety, while the transparent window or cut-out offers interaction with the product.

Use Cases: Household goods, confections, toys, artisanal products

Shrink wrap is a flexible, clear plastic material that, when heat is applied, shrinks tightly over whatever it is covering. This form of packaging is known for its ability to conform precisely to the product’s shape, providing a secure fit and ensuring the product is sealed and protected from external elements.

One of the primary benefits of shrink wrap is its space-saving attribute. By fitting snugly around products, it minimises the amount of excess packaging material used, optimising storage and shelf space in retail environments. Additionally, its transparent nature allows for easy product identification and inspection without the need to open or tamper with the packaging.

Use Cases: Bundling products together (like multi-packs of beverages), protecting individual and boxed products, securing items on pallets during transportation, and perishable goods like fresh produce or meats

Flow wraps, also known as horizontal form-fill-seal wraps, are continuous rolls of plastic film used to package various products. The product is placed on the film, which is then folded over and sealed on all sides, typically using heat. This method ensures a tight, secure wrap around the product, safeguarding it from external contaminants and preserving its freshness.

A distinct advantage of flow wraps is their adaptability. The machinery used for flow wrapping can be adjusted to accommodate different product sizes, making it a versatile packaging solution.

Flow wraps are often used when a product requires an airtight seal to maintain freshness or to extend shelf life. This tight seal ensures minimal air exposure, which is crucial for certain perishable goods.

Use Cases: Fresh produce, snack bars, candies, baked goods, and medical equipment like syringes that require a sterile environment.

Tray and hood packaging is a prevalent form of shelf-ready packaging, primarily designed for products with inherent stacking strength. The design typically comprises a tray, which acts as the secondary packaging, and a hood or cover that protects the product.

The tray provides a stable base, ensuring the products remain organised and easily accessible. The hood can be easily removed, often designed with perforations, to reveal the products inside, making it ready for shelf display.

This packaging style is particularly beneficial for products that must be displayed prominently on retail shelves, allowing for easy restocking and product rotation. The tray and hood design also ensures that products are protected during transit and remain in pristine condition until they reach the consumer.

Use Cases: Glass jars, plastic-filled bottles, lightweight products, and irregularly shaped items.

The U-shaped Tray & Hood design is a variation of the standard Tray & Hood packaging.

What sets it apart is its unique U-shaped contour tray, which is specifically crafted to cradle and support products more securely. This design is particularly advantageous for items that are taller or have an irregular shape, as the U-shaped base provides a snug fit, ensuring that the products are held firmly in place.

The hood, often made of transparent material or designed with perforations, covers the products during transit. When the products are ready for display, the hood can be effortlessly removed, revealing the items nestled within the U-shaped tray.

Use Cases: Taller bottled products, uniquely shaped items like spray bottles, and bagged products that need additional support to stand upright.

The Tray & Wrap (Shrink) design is a combination of a sturdy tray with a shrink wrap finish.

The products are first placed on the tray, providing a solid base and organisation. Following this, a shrink wrap is applied over the products and the tray. When heat is introduced, the film shrinks, tightly enveloping the products and ensuring they remain secure and protected.

This packaging design is especially beneficial for products that are self-supporting and need to be held together as a unit. The shrink wrap ensures a tight seal, protecting the products from external contaminants, while the tray offers structural support. The transparent nature of the shrink wrap allows for easy product identification and inspection, making it a preferred choice for many retailers.

Use Cases: Glass jars, tin cans, larger plastic jars or bottles with sealed lidding, and products that need to be bundled together for promotional offers or bulk sales.

The Angled Tray & Hood design is a specialised variation of the traditional Tray & Hood packaging.

As the name suggests, the tray in this design is angled, providing a tilted platform for the products. This tilt ensures that products, especially those that are non-supporting or lightweight, are presented at an angle that enhances visibility and accessibility on retail shelves. The angled presentation can also trigger impulse purchases, especially when placed at strategic points within a store.

Use Cases: Bagged products that might slump in standard packaging, shaped plastic bottles, tubs or jars

The Regular Slotted Carton, also called a Perforated Display Box, is a unique packaging solution that combines the simplicity of a standard carton box with the functionality of a display-ready package.

Constructed as a single piece, this carton-type features perforated lines that allow for easy transformation. Initially, it appears and functions as a regular carton box, providing protection during shipping and storage. However, once it reaches the retailer, the perforated sections can be torn away, converting the carton into a custom display box.

Use Cases: Products that require bulk shipping and a quick transition from shipping mode to display mode, such as snacks, beverages, household items, and more.

Half Slotted Cartons are a variation of the regular slotted carton, distinguished by their open top. Essentially, an HSC consists of a single piece of cardboard that forms the bottom and sides of the box, featuring equal-sized flaps that meet at the centre. The top remains open, making it ideal for products that need to be accessed frequently or quickly.

Use Cases: Items that need to be loaded quickly and efficiently, such as fruits and vegetables in grocery stores, automotive parts in service centres, or bulk items in warehouse clubs.

The Half Slotted Carton (HSC) and Tray Combo is an innovative packaging solution that merges the design of the HSC with an additional tray component. This combination provides dual functionality. The HSC offers the primary containment for the product. At the same time, the tray serves as a supportive base or an additional layer for product arrangement.

This design ensures enhanced stability, especially for products that might shift during transportation or display. The tray can also act as a secondary display platform, elevating the product for better visibility or segregating different products within the same HSC.

Use Cases: Products that require a stable base due to their weight or shape, multi-product displays in retail environments, or items that benefit from a raised or tiered presentation.

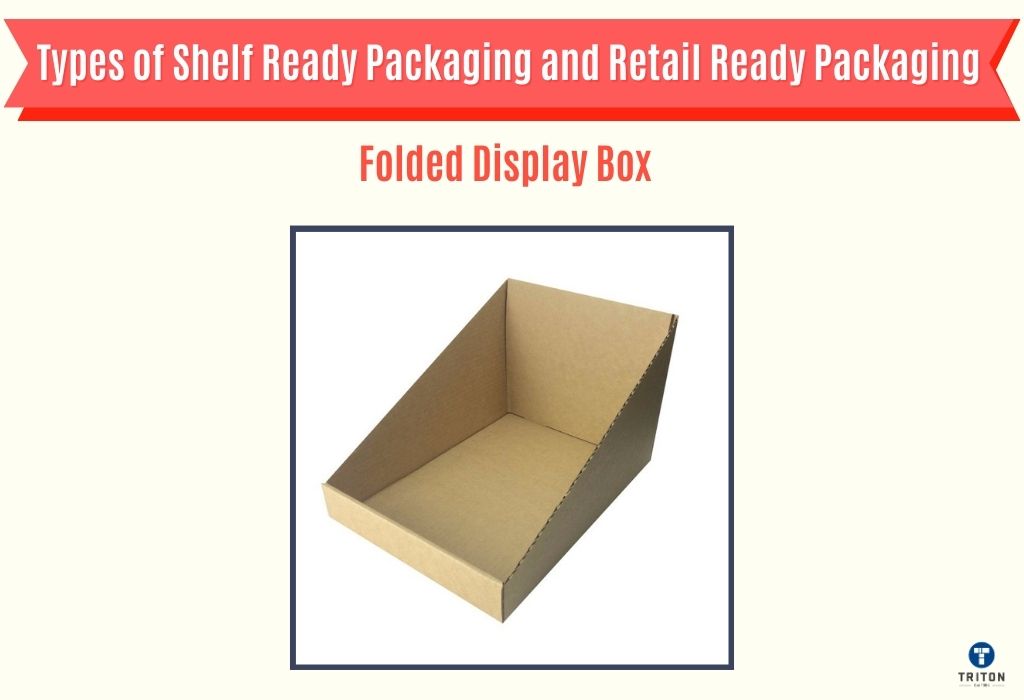

A Folded Display Box is a versatile packaging solution that seamlessly transits from a protective shipping container to an attractive display unit. Crafted primarily from corrugated cardboard or other sturdy materials, this box features an over-flap head. When the product reaches its retail destination, this flap can be folded down to the base of the box, transforming it into a display-ready format.

The folding mechanism also allows for customisation, where brands can print marketing or product information on the inside flap, which becomes visible once folded down.

Use Cases: Products that benefit from an elevated display in retail settings, such as cosmetics, specialty foods, toys, or promotional items that require a quick transition from shipping to shelf display.

Shelf Trays are a staple in retail environments, designed to offer both protection and presentation for products. Typically made from corrugated cardboard and plastic, these trays are sturdy enough to hold multiple products while also being lightweight for easy handling. The primary design feature of a shelf tray is its open top, allowing for products to be easily viewed and accessed by consumers.

The simplicity of the shelf tray design ensures that products are front and centre, making it an ideal choice for items that benefit from being prominently displayed. Additionally, these trays can be easily stacked, making them a space-efficient solution for retailers.

Use Cases: Fast-moving consumer goods, snacks, beverages, personal care products, and any items in promotional displays.

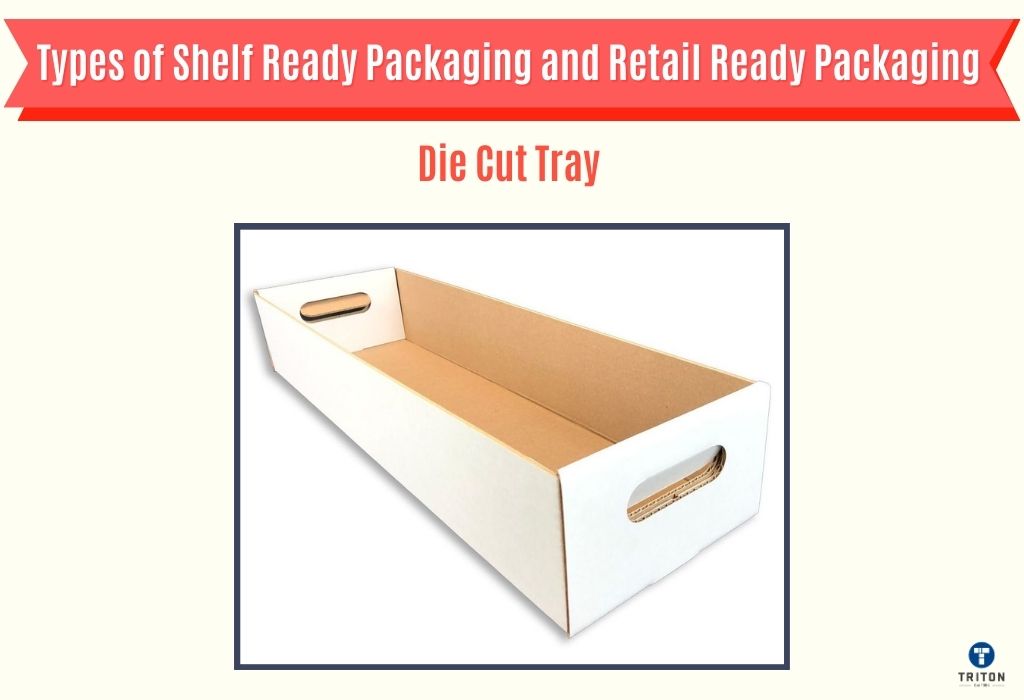

Die Cut Trays are custom-designed trays made from flat sheets of material, predominantly corrugated cardboard, which are then cut, folded, and assembled into a tray shape. The “die-cutting” process involves using a die (a specialised tool) to cut the material into specific shapes and designs. These trays can be assembled either by machines (Machine Erect) or manually (Hand Erect), depending on the volume of production and specific requirements.

The hallmark of Die Cut Trays is their adaptability and customisability. They can be meticulously tailored to accommodate the exact dimensions and contours of a product, ensuring a snug fit and superior protection.

The precision of the die-cutting process allows for intricate designs and features, such as handles, special locking mechanisms and ventilation holes, to be incorporated into the tray. These trays can also be designed with high-quality litho-laminated cartons for a premium appearance or plain octagonal trays where the product itself is the primary focus.

Use Cases: Products demanding a custom fit, items with unconventional shapes, luxury or artisanal goods, and products where packaging significantly influences the overall presentation, such as gourmet foods, high-end electronics, or specialty gifts.

Reinforced Club Store Trays are robust packaging solutions specifically designed to handle the demands of bulk retail environments like club stores. Made predominantly from corrugated cardboard, these trays are reinforced to carry heavier loads, ensuring that products remain secure and intact even when stacked or subjected to the rigours of a busy retail setting.

The reinforcement is often achieved through added layers or specific design elements, ensuring the tray can support products without buckling or deforming. Their design ensures durability without compromising product visibility or accessibility, essential in fast-paced club stores.

Use Cases: Bulk items in wholesale club stores, larger quantities of products like beverages, canned goods, or multipacks, and any product that requires additional support due to its weight or volume.

Top Tear-Away Trays are shelf-ready packaging designed for quick and efficient product access. Made primarily from corrugated cardboard or similar sturdy materials, these trays feature a perforated top section. Retailers can easily tear away this top portion, transforming the closed box into an open tray ready for shelf display.

The primary advantage of this design is its convenience. It allows for swift product stocking and reduces the need for additional unpacking or setup. Once the top is torn away, the products inside are immediately accessible and presented in an organised manner, making it easier for consumers to pick and purchase.

Use Cases: Products that require rapid shelf stocking in retail environments, such as snacks, confectioneries, personal care items

PDQ, short for Pretty Damn Quick or Product Displayed Quickly Trays, is a popular choice in retail environments for its efficiency and ease of use. Crafted primarily from corrugated cardboard, these trays are designed to be quickly and easily loaded onto store shelves. The name itself suggests the speed and convenience associated with this packaging solution.

The design of PDQ Trays often includes a rear-loading feature, allowing stockers to replenish products from behind without disturbing the front-facing display. This ensures that the products remain organised and presented attractively to the consumer, even as stock levels change. Additionally, PDQ Trays often come with printed graphics, enhancing brand visibility and providing product information directly on the tray.

Use Cases: Fast-moving consumer goods, promotional items, seasonal products, and products placed near point-of-sale displays and promotional counters

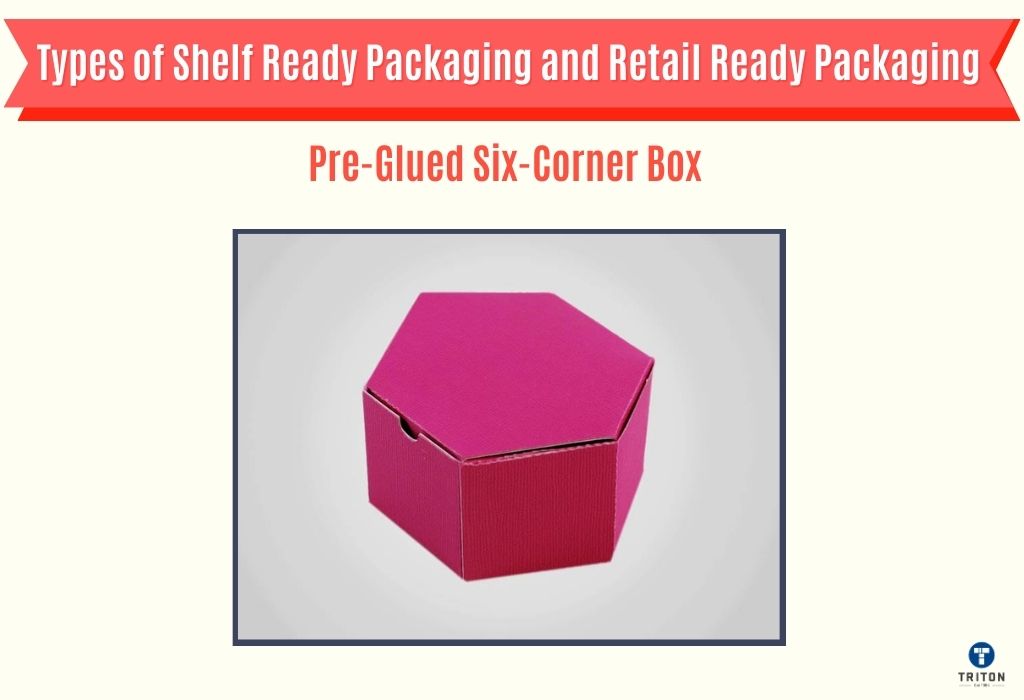

The Pre-Glued Six-Corner Box is a unique packaging solution that combines efficiency and structural integrity. Made from a range of materials, including corrugated cardboard, kraft paper, and even certain plastics, this box is characterised by its six corners that are pre-glued, ensuring a seamless and swift assembly process.

Its design is a testament to the balance between form and function. The six-corner structure not only imparts a unique aesthetic appeal but also offers enhanced stability and protection to the contents within.

Use Cases: Fragile items like ceramics or glassware, premium products, boutique cosmetics, artisanal crafts

Merchandising units are strategic packaging solutions that maximise product visibility and drive impulse purchases in retail environments. Often made from a combination of corrugated cardboard, plastic, and sometimes metal, these units are larger than typical packaging and are used for secondary placements or promotional displays.

The design of merchandising units is tailored to grab the consumer’s attention. They often feature bold graphics, brand logos, and product information, making them stand out in a crowded retail space. Additionally, these single units are designed to hold a substantial number of products, making them ideal for promotional events or product launches.

Use Cases: Promotional goods, seasonal products, new product launches, and fast-moving products that benefit from secondary placements to boost sales.

Retail-ready packaging offers a plethora of advantages to both retailers and suppliers, enhancing the overall shopping experience while ensuring efficiency and cost-effectiveness.

Here are the top five benefits of shelf-ready packaging.

For a deeper dive into the myriad benefits of retail-ready packaging and how it’s revolutionising the retail industry, check out our detailed article on the benefits of retail-ready packaging.

While retail-ready packaging offers a myriad of benefits, it’s crucial to weigh its potential drawbacks to make an informed decision. Here’s a comprehensive look at some challenges associated with this shelf-ready packaging solution:

Retail and shelf-ready packaging has evolved to meet the dynamic needs of both retailers and consumers. Central to this evolution is the concept of the “Five Easies.”

The “Five Easies” are fundamental principles that guide the design and functionality of retail-ready and shelf-ready packaging. These principles ensure that the packaging meets the needs of retailers and also enhances the shopping experience for consumers.

Here’s a closer look at each of these principles.

The principle of being “Easy to Identify” emphasises the importance of clear and recognisable packaging. It ensures that both retailers and consumers can swiftly discern the product inside the packaging without the need to open it.

Clear and recognisable packaging also aids in the correct product choice and stock rotation throughout the supply chain, especially in distribution centres and during simple shelf replenishment processes.

Tips for Implementation:

Explore our comprehensive guides on barcoding technology.

“Easy to Open” underscores the necessity for packaging that can be effortlessly open.

Ideally, the package should easily open in one or two steps and preferably without using tools such as knives. Moreover, the package opening process should be straightforward, such that the store personnel should be able to figure out how to open, use, and dispose of the product.

Tips for Implementation:

The “Easy to Shelf” principle is all about ensuring that once the packaging is opened, products can be placed on the shelf with minimal handling or rearranging. This means the packaging design should align with standard shelf dimensions and consider how the product will sit once displayed. Adhering to this principle can significantly reduce the labour and time required for stocking.

Tips for Implementation:

The “Easy to Shop” principle emphasises a consumer-centric approach to packaging. This principle is all about ensuring that the packaging showcases the product effectively and also facilitates a seamless and intuitive shopping experience.

At its core, this principle dictates that packaging should not create barriers to purchase. Whether a consumer is familiar with the brand or is a first-time shopper, they should be able to easily identify, access, and select the product from the shelf. This means clear product visibility, easy access for consumers to pick up and examine, and informative packaging that communicates product benefits and features.

Tips for Implementation:

Lastly, the “Easy to Dispose” principle focuses on the post-purchase phase. This principle underscores the importance of environmental responsibility in packaging design. It emphasises that once the product has been sold or when restocking is required, the packaging should be easy to handle and straightforward to recycle or dispose of.

A key aspect of this principle is to use recyclable materials and minimise mixed materials that complicate the recycling process.

Tips for Implementation:

Creating effective shelf-ready and retail-ready packaging is a meticulous process that requires a balance of aesthetics, functionality, and practicality. As brands strive to make their products stand out on the shelves while meeting retailer demands, it’s crucial to follow a structured approach.

Here are some pivotal questions you should answer when making reading packaging.

Navigating the intricacies of industry specification requirements can be challenging. To assist you, Triton offers dedicated guides that delve into the specifics of each requirement. Here are the guides available:

SRP and RRP have emerged as game-changers in the retail landscape, particularly for large-scale retailers. The decision to choose SRP over traditional individual packaging is influenced by various factors. Here’s a breakdown of situations where opting for SRP might be the better choice:

The packaging industry is in a constant state of evolution, driven by technological advancements, changing consumer preferences, and environmental concerns. As we look ahead, several key trends are poised to shape the future of ready packaging. Here’s a closer look at these emerging trends:

The global push towards sustainability is not just a trend but a necessity. As environmental concerns rise, there’s a growing emphasis on eco-friendly materials and designs in the packaging sector.

Brands are increasingly recognising the importance of sustainable practices, not just for the environment but also as a competitive advantage. Consumers are more informed and prefer products with minimal environmental impact.

As a result, we can expect a surge in the use of biodegradable materials, a reduction in single-use plastics, and designs that minimise waste. Additionally, the focus will also be on the entire lifecycle of the packaging, from sourcing raw materials to disposal, ensuring a reduced carbon footprint.

The integration of technology into packaging, often termed ‘smart packaging’, is set to redefine consumer engagement.

One prominent example is the use of QR codes. By simply scanning a QR code with a smartphone, consumers can access a wealth of information about the product, from its origin to its nutritional facts. But the potential of smart packaging goes beyond QR codes.

Innovations like augmented reality experiences and even sensors that monitor product freshness are on the horizon. These technologies not only enhance the user experience but also provide brands with valuable data on consumer behaviour.

Considering integrating QR codes into your packaging? These guides will provide valuable insights:

And if you are keen on learning the working principle behind QR codes, our How QR Codes Work will be of assistance.

In an era where consumers value unique experiences, personalisation in packaging is gaining traction. Tailoring packaging to individual consumer preferences can create a deeper connection between the brand and its customers. This could range from personalised messages on the packaging to designs that resonate with specific demographics.

With advancements in printing technology, it’s becoming feasible to produce packaging in smaller, customised batches. As brands strive to stand out in a crowded market, offering a personalised touch can be a significant differentiator.

In conclusion, the future of ready packaging is exciting and dynamic. As brands adapt to these trends, consumers can expect more innovative, eco-friendly, and personalised packaging solutions in the coming years.

An RRP box, or Retail Ready Packaging Box, is the outer transit box that houses products intended for retail sale.

Yes, different retailers often have different requirements for shelf-ready packaging. These requirements are based on the retailer’s store layout, warehouse operations, branding guidelines, sustainability goals, and promotional strategies.

It’s crucial for suppliers to understand and adapt to these unique specifications to ensure smooth stocking and optimal product presentation.

The need for a packaging machine depends on the design of the SRP. Some SRP designs can be manually assembled and filled, while others are better suited for automated assembly and filling. Often, manufacturers begin with a manual approach and may transition to automation after the initial success.

Shelf-ready and retail-ready packaging represent a transformative approach in the retail packaging sector, streamlining the transition from warehouse to store shelf. These packaging methods, often used interchangeably, prioritise efficiency, aesthetics, and a “ready-to-sell” strategy.

As consumer preferences evolve and environmental concerns gain prominence, the significance of such packaging solutions is further amplified. They not only cater to the logistical needs of retailers but also resonate with the modern consumer’s demand for sustainability and convenience.

Shelf-ready and retail-ready packaging styles are more than just packaging solutions; they are strategic tools that brands can leverage to enhance visibility, reduce costs, and drive sales.

We hope this article was useful.

Thanks for reading!

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below