A barcode quiet zone is a clear, unmarked area surrounding all four sides of a barcode. It marks the starting and ending points of the barcode pattern, ensuring that a barcode scanner can identify the barcode and read the encoded data correctly. The quiet zone must be free of any text, graphics, or other marks to prevent interference with the scanning process.

In this article, we will explore the significance of quiet zones, delve into the quiet zone specifications for various barcode formats, and conclude with insights on designing and printing barcodes that maintain sufficient quiet zones for optimal scanning performance.

For a solid understanding of the basic principles behind barcodes, delve into our article, What is a Barcode? And for a comprehensive overview of the different barcode types available, take advantage of our guide on Barcode Types.

Barcode quiet zones are fundamental to the accuracy and efficiency of barcode scanning. They prevent scanning errors by ensuring that scanners do not pick up extraneous signals from adjacent patterns or signals. This clarity is essential for the rapid and reliable decoding of barcodes.

A well-defined quiet zone acts as a buffer, safeguarding the barcode’s readability and, by extension, supporting the seamless operation of scanning systems. These zones are indispensable in maintaining the speed and reliability of checkout operations and supply chain management, where accurate data capture is paramount.

At Triton, we pride ourselves on offering a comprehensive array of barcode scanners from industry-leading brands such as Honeywell and Zebra.

Our comprehensive inventory stocks various barcode scanner types, such as mobile terminals, general-purpose scanners, rugged scanners, fixed scanners and sensors, USB scanners, wireless scanners, Bluetooth scanners and 2D scanners, all offering reliable and advanced barcode reading capabilities.

Understanding the importance of operational continuity, Triton extends its offerings to include a vast inventory of accessories, spare parts and cables, ensuring that your equipment consistently operates at its best.

For personalised guidance and expert advice tailored to your business’s needs, contact us via our live chat widget below.

The requirements for quiet zones vary significantly across different types of barcodes, each designed to meet specific needs and applications. Understanding these requirements is crucial for ensuring the reliability and efficiency of barcode scanning systems.

Here’s a breakdown of quiet zone specifications for various barcode formats:

1D barcodes, or linear barcodes, encode data using parallel lines of varying widths and spacings. The parallel lines represent binary digits 0 and 1, used in a sequence to represent numbers from 0 to 9. These barcodes are integral to operations in retail, inventory management, and beyond.

Note: In the context of 1D barcode specifications, “X”, called X-dimension, represents the width of the narrowest bar within the barcode.

2D barcodes, also known as matrix barcodes, employ a sophisticated pattern of squares, dots, and other shapes to encode data across two dimensions. These barcodes significantly expand capacity by utilising both horizontal and vertical planes for data storage, accommodating everything from text and URLs to images.

Note: In the context of 2D barcodes, “X” denotes the dimension of the smallest individual square or dot that forms part of the barcode’s pattern.

For an in-depth comparison and understanding of 1D and 2D barcodes, be sure to explore our detailed guide, 1D vs 2D Barcode.

To ensure the effectiveness of barcode scanning systems, it’s important to focus on the design processes of barcodes, particularly the maintenance of the quiet zone. Here are some essential guidelines to ensure your barcodes meet the necessary specifications for their intended application:

Familiarise yourself with the specific quiet zone requirements for the barcode symbology you are using. This knowledge is crucial for preventing scanning errors and ensuring seamless operational efficiency.

When designing your barcode, incorporate the required quiet zone space from the outset. This approach ensures that the entire barcode, including its margins, fits the intended label or packaging space without adjustments that could compromise the quiet zone.

Ensure the quiet zone is free of marks, text, or designs. This clarity is essential for the barcode scanner to distinguish the barcode from its surrounding environment, facilitating accurate scanning.

Account for potential printing variabilities that might encroach on the quiet zone. Factors such as ink spread and label positioning can affect the actual size of the quiet zone, so it’s wise to allow a little extra space as a buffer.

After designing and printing, test your barcodes under real-world conditions. This testing should include various scanning environments and angles to verify the barcode’s readability across different scenarios.

Educate your team about the importance of quiet zones in barcode scanning. Awareness can prevent mistakes in the design and printing processes that compromise the effectiveness of the quiet zone.

Discover more tips and tricks for designing barcode labels by exploring our articles: Common Mistakes to Avoid When Designing Barcodes and Best Practices for Designing Perfect Labels and Barcodes.

Navigating the complexities of barcode design and printing can be daunting, especially when considering critical elements like quiet zones, which are essential for error-free scanning but often neglected. This oversight underscores the importance of choosing the right tools for barcode generation.

While free barcode generator software might seem appealing due to its cost-effectiveness, it often fails to deliver the high-quality, customisable barcode solutions that businesses require. These limitations include inadequate quality control, limited customisation options, and a lack of support for advanced barcode standards, which can significantly impact operational efficiency and compliance.

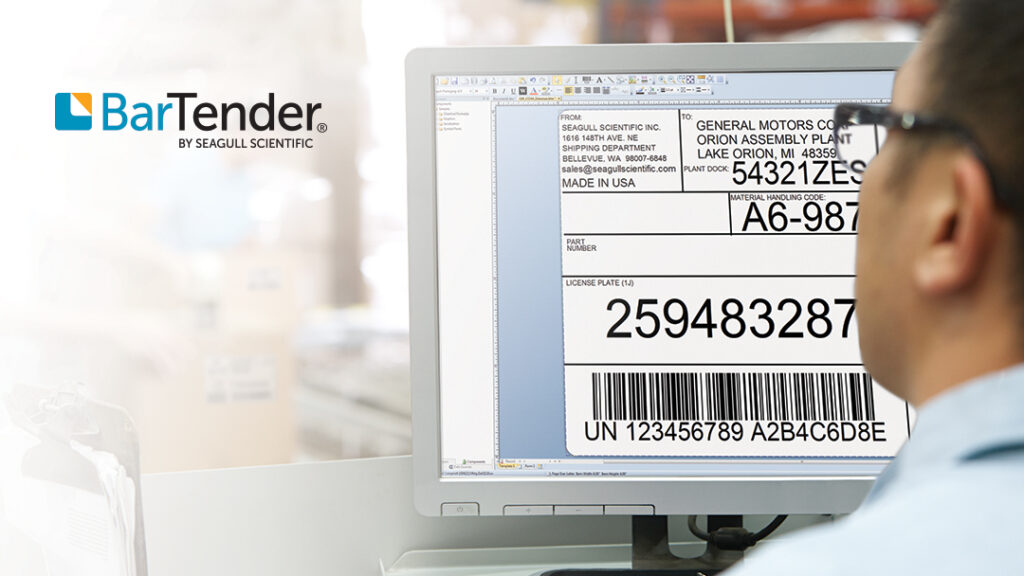

Enter BarTender by Seagull Scientific, a premium solution that transcends the capabilities of free generators. BarTender is not just a label designing tool; it’s a comprehensive suite for creating high-quality labels, barcodes, RFID tags, and more, designed to integrate flawlessly into your existing infrastructure.

BarTender distinguishes itself with user-friendly design tools that simplify label and barcode creation, eliminating the need for extensive programming skills. With over 400 pre-formatted, ready-to-use barcode components and support for 105 symbologies, BarTender caters to various industry standards. The software’s extensive template library, coupled with its ability to connect to various data sources like databases and CSV files and its advanced date/time serialisation features, make it a versatile choice for generating diverse barcodes and labels.

Discover more about BarTender’s extensive features in our article, What is BarTender?

At Triton Store, we proudly offer all four editions of BarTender software: Starter Edition, Professional Edition, Automation Edition and Enterprise Edition, alongside BarTender Cloud—a cloud-based solution for remote label printing and management, ensuring accessibility from anywhere.

For insights into how BarTender Cloud compares to its on-premise counterparts, delve into our article, BarTender Cloud vs BarTender Software.

No, not all barcode symbologies necessitate a quiet zone. This is primarily because some barcodes incorporate unique centre locator patterns or possess specific design characteristics that inherently differentiate the barcode from its surrounding environment.

Examples of barcodes that do not require quiet zones include Aztec code and DotCode.

The absence of a quiet zone in barcode types that require a quiet zone can lead to scanning errors. Scanners might not accurately identify the start and end of the barcode, resulting in failed scans or incorrect data interpretation.

In labels, the quiet zone refers to the clear, unprinted space surrounding a complete barcode (i.e. barcode with the quiet zone). This area is free from text, graphics, and other markings, ensuring that barcode scanners can effectively read the barcode without interference. It acts as a buffer zone that enhances the readability and accuracy of the scan.

The size of the quiet zone varies depending on the barcode symbology.

For 1D barcodes like UPC and EAN, the quiet zone typically requires a space at least 9 times the width of the narrowest bar on either side.

For 2D barcodes such as QR codes, a quiet zone on all sides that is 4 times the size of the smallest element is recommended.

Printing materials can significantly impact the quiet zone. Materials that cause ink spread or fading can encroach on the quiet zone, reducing scan reliability. Therefore, choosing materials compatible with your printing method is crucial.

Repairing a damaged quiet zone on a printed barcode is challenging and often impractical. The best approach is to reprint the barcode according to the original specifications to ensure its integrity and scalability.

Different barcode scanners may have varying sensitivities to quiet zone variations. High-quality scanners might compensate for minor quiet zone issues, but adhering to the recommended specifications is advisable for universal compatibility.

The quiet zone is a fundamental component of barcode technology, essential for ensuring the accuracy and efficiency of barcode scanning systems.

Adhering to the quiet zone requirements for different barcode types, utilising appropriate design and printing techniques, and conducting thorough testing is critical for maintaining barcode integrity.

By prioritising these aspects, businesses can enhance operational efficiency, reduce the risk of scanning errors, and ensure seamless transactions across various industries.

We hope this article was useful.

Thanks for reading!

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below

Melbourne

Brisbane

Phone 1300 558 438

Live Chat – Widget below